Daubert Chemical Co., makers of cavity wax and wax-based underbody coatings, highlights the Nox-Rust series of products as winterization solutions for fleets. The Nox-Rust 1210HP hot-melt corrosion preventative in and on structural components can defend against the effects of moisture, road debris and chemicals. Nox-Rust X-121B can be used as an aftermarket solution, to stop active corrosion, and as an extra layer of protection.

Nox-Rust 1210HP

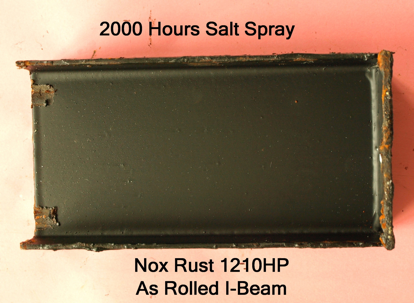

Daubert’s Nox-Rust 1210HP is a hot melt corrosion preventive coating is designed to be applied to various truck trailer structural members from a heated dip coating tank. The coating hardens upon cooling to form a dry, wax-like film. Nox-Rust 1210HP can also be used for other applications where excellent corrosion protection is desired.

The product can be applied to a wide variety of substrates and requires far less surface preparation than competing anticorrosive coating technologies. Nox-Rust 1210HP also exhibits superior adhesion to welds and demonstrates resilience even when exposed to post-coating assembly processes using welds or mechanical fasteners like screws and bolts, the company said.

“By using products like Nox-Rust 1210HP to protect components, engineers have greater flexibility when choosing materials and construction methods,” said Mike Duncan, Ph.D., vice president technology for Daubert Chemical. “Thinner, higher-alloy steel can last much longer and welded areas are far better protected. By leveraging the superior coverage that submersion in a wax-based coating like Nox-Rust 1210HP affords, I-beam, C-channel and tubular steel structural components can all receive the same optimum level of anticorrosion protection.”

In final assembly scenarios, where coating abrasion is often inevitable, the pliable Nox-Rust 1210HP coating exhibits self-healing characteristics that maintain a residual anticorrosive barrier. Nox-Rust coatings also come in the form of a touchup solution that can be applied to areas where a component’s coating has been compromised in the assembly process. Nox-Rust 1210HP, according to the company, provides greater corrosion resistance or “high performance” when measured in accelerated lab tests than the original Nox-Rust 1210.

Other features of the Nox-Rust 1210HP include:

• Elimination of volatile solvents and the fire, health hazards, and pollution problems related to them.

• No loss of material during application; nearly 100 percent utilization.

• Uniform and complete coating of intricate parts, box sections and channels.

• Improved overall corrosion protection due to coating uniformity and process control.

Nox-Rust X-121B

Nox-Rust X-121B is a thixotropic wax-gel rust proofing compound designed to provide a long-term protective film for primed and unprimed steel. Nox-Rust X-121B flows when applied and dries to a firm wax-like film that will repel water, self-heal, and remain flexible at low temperatures.

Nox-Rust X-121B comes in a convenient aerosol can that can be sprayed for touch-up applications. The product also comes in larger industrial quantities that can be applied to larger areas using low-pressure airless equipment.

“As part of a regular PM, fleets can inspect a vehicle for telltale signs of corrosion and can apply Nox-Rust X-121B directly on trouble spots with active rust,” Duncan said. “The product dramatically inhibits the oxidation process and prevents further damage from occurring. Nox-Rust X-121B can also be widely applied to areas of a vehicle where nicks and abrasion have compromised original protective coatings.”

Nox-Rust X-121B can be applied to some previously coated substrates and interacts well with galvanized, E-coated, powder-coated and liquid-coated steel. Unlike other traditional corrosion-resistant coatings, surfaces treated with Nox-Rust X-121B require no preparation before accepting new welds.

Nox-Rust X-121B is particularly effective at protecting a vehicles undercarriage, which is one of the most challenging environments for any corrosion prevention plan of attack. Because it is compatible with both finished and unfinished metal, little if any prep is required before application.

Nox-Rust X-121B can also be used to treat areas where repair work has created exposed metal and over new welds. Additionally, the product inhibits the galvanic response caused when stainless steel nuts and bolts make contact with carbon steel components.

Other features of the Nox-Rust X-121B include:

• A thixotropic wax-gel rust proofing compound.

• Designed to provide a long-term protective film.

• For use on primed and unprimed steel.

• Available in aerosol and non-aerosol form.