Recently, I was answering truck driver questions regarding tires and wheels on a national satellite trucking radio show. During the hour event, most of the questions centered on the confusion associated with the information molded onto a truck tire sidewall. These truckers were justified in their uncertainty—there is a lot of information, which is not always clear. In most cases, the same information is available on either sidewall with one exception, the official DOT number is only found on one side.

Tire DOT numbers are unique for a specific tire make/model and size for a given week of production. If 1,000 tires are produced in the same manufacturing plant and the tires are the same model, size and load range then all 1,000 tires will have exactly the same identical DOT number molded on the sidewall if they were produced during the same week. Just about every tire manufacturer changes the DOT week number on a Sunday. Why? Tradition.

Every time a commercial truck tire casing is retreaded, a new retread DOT number must be branded onto the tire sidewall preferably near the original DOT number. A new tire DOT number is comprised of a total of 11 digits when compared to the retread DOT which has 13 digits.

The first two digits: Tire plant code

(Every tire plant in the world is assigned a unique two digit code. The NHTSA website is the best source to determine which code represents what specific new tire or retread plant.)

The second five digits: Tire construction information (This is unique for each tire construction).

The last four digits: Week and year tire was produced: 4401 = 44th week of 2001.

The most important information regarding the DOT from a fleet perspective is the last four numbers that represent the week and the year of production.

The tire sidewall tells a history of the tire. A fleet can determine how many retreads the casing received and which plants produced each retread and new tire. The age of the casing can also easily be calculated through the original DOT number.

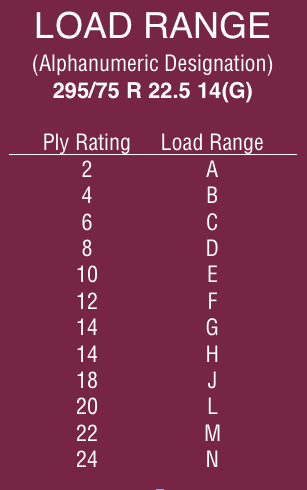

Tire make, model, size, load range and ply rating are also molded on the tire sidewall. Load range and ply rating go together. The most common truck tire load range is G or 14 ply rating. In linehaul fleet operations, drive and trailer tires are typically LR-G while LR-H is required for those fleets running higher-rated steer axles that must have tires with more weight capacity. LR-G and H tires for a given tire make/model have the same overall dimensions; however, the LR-H tires will be heavier and more costly to purchase. To support the increased load, these LR-H tires will have been built with a heavier gauge steel wire construction. You will also find on the tire sidewall specific load and inflation information.

Tire make, model, size, load range and ply rating are also molded on the tire sidewall. Load range and ply rating go together. The most common truck tire load range is G or 14 ply rating. In linehaul fleet operations, drive and trailer tires are typically LR-G while LR-H is required for those fleets running higher-rated steer axles that must have tires with more weight capacity. LR-G and H tires for a given tire make/model have the same overall dimensions; however, the LR-H tires will be heavier and more costly to purchase. To support the increased load, these LR-H tires will have been built with a heavier gauge steel wire construction. You will also find on the tire sidewall specific load and inflation information.

The maximum individual tire load is listed at a specific tire pressure. To add confusion, the maximum load and inflation is shown for running the tire as a single or as a dual configuration. Just because the tire sidewall is stamped 120 PSI does not imply that is the pressure that you should be running at your fleet. The recommended fleet pressure is based on your worst case load scenario. Load/inflation tables published by all the tire companies will determine the recommended pressure for your vehicle loads.

It is always good practice to work with your tire professional if you have questions regarding the information molded onto every tire sidewall.