Ever since the Federal Motor Carriers Safety Administration launched its initiative called Compliance, Safety, Accountability (CSA) there has been increased attention to the condition of over-the-road equipment. Everyone wants to avoid problems during a roadside inspection because every infraction will be reported to the FMCSA and made public via the Internet.

According to some fleet managers, compliance involving vehicle condition is not difficult. For example, Andy Stopka, vice president of Maintenance at NationaLease, said, “CSA citations can be avoided if everyone does proper due diligence during PM inspections. The biggest problems are caused by people’s inactivity. When PMs are being done properly, the truck will make it to the next PM. Other than a light getting broken or a tire picking up a nail, concerns about CSA should be minimal on the road from a maintenance perspective.”

If Stopka is right, and he most likely is, the major problem is not directly equipment related. The major challenge is for everybody in the maintenance shop to be diligent in making sure that everything is running in a well-maintained condition. That means formal PM inspections are thorough and followed by promptly correcting any equipment found. It also means that drivers make a careful pre-trip vehicle inspection and make sure problems are corrected before starting a trip.

What’s it all about?

When the CSA program was first launched, then Transportation Secretary Ray LaHood said, “The CSA program will help us more easily identify unsafe commercial truck and bus companies. Better data and targeted enforcement will raise the safety bar for commercial carriers and empower them to take action before safety problems occur.”

The centerpiece of CSA is the Safety Measurement System (SMS), which analyzes all safety-based violations from roadside inspections and crash data to determine a commercial motor carrier’s on-road performance. SMS assigns points to violations and charges them to both drivers and carrier companies. The measurement system uses a number of safety related categories to examine a carrier’s on-road performance and potential crash risk. One of which is vehicle maintenance, which, of course, is the responsibility of the fleet manager.

Using this information over time, FMCSA is able to identify carriers with patterns of high-risk behaviors and intervene with information necessary for them to change unsafe practices early on. Such interventions include early warning letters, targeted roadside inspections and focused compliance reviews that concentrate enforcement resources on specific issues.

Carrier and driver scores are easily accessible via the Internet to encourage improvements in motor carrier safety and empower carriers and other firms (e.g., shippers, insurers) involved with the motor carrier industry to make safety-based business decisions.

The SMS will continuously monitor on-road performance to assess whether an entity‘s safety performance has improved enough for it to exit the Intervention Process or if further intervention is warranted. If a carrier does not take the appropriate corrective action, FMCSA imposes civil penalties.

The results so far

The program is clearly improving safety on our highways. According to Duane DeBruyne of the FMCSA’s Office of Communications, there has been a dramatic decrease in safety violations—down 14%, and driver violations are down 17% per roadside inspection. Moreover, the SMS has enough performance data to evaluate nearly 40% of the carriers that have been involved in more than 92% of reported crashes.

Such observations are supported in the results of an independent study of the program done by University of Michigan Transportation Research Institute (UMTRI) that reported crash rates were higher for motor carriers identified with safety problems by the program than for motor carriers not so identified. In fact, the crash rate for motor carriers that were identified with safety was more than three times greater than the crash rate for motor carriers not identified with any safety problems.

More importantly, the UMTRI study found that the effect of a warning letter produced significant results. Twelve months after receiving a warning letter 83% of the notified carriers had resolved identified safety problems and only 17% continued to have safety problems.

Carrier responsibilities

The CSA program is readily available on the FMCSA website. Everything you might need is found in sections 393 and 396. In these documents you will find:

• That motor carriers and intermodal equipment providers must regularly inspect, maintain and repair all motor vehicles and intermodal equipment under their control.

• That records must be available that include an identification of the vehicle, including company number, make, serial number, model year and tire size. They must also include a means to identify the nature and due date of the various inspection and maintenance operations scheduled and a record of inspection, repairs and maintenance indicating their date and nature.

• That such records must be retained where the vehicle was either housed or maintained for a period of one and a half years after it leaves the carrier’s control.

Problem areas

Not surprisingly, the top equipment-related areas that present the most frequent problem areas for fleets during road side inspections are brakes, tires and the electrical system, particularly but not exclusively lights. Such a situation certainly supports NationaLease’s Stopka when he said, “CSA citations can be avoided if everyone does proper due diligence during PM inspections.” This is especially true if driver pre-trip inspections are added to PM inspections.

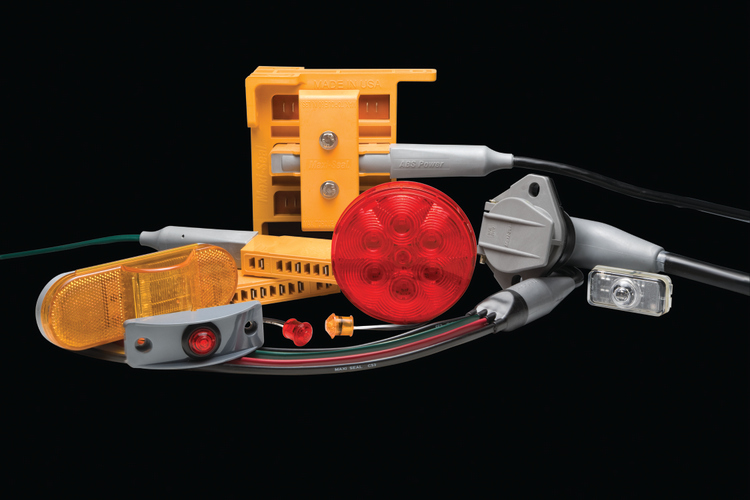

The most frequent vehicle violation is not having required lamps in working condition. The use of LED lighting systems have been proven over and over again to save fleets money. Every over-the-road fleet should be using them. According to Tim Gilbert, director of Heavy-duty Fleet and OEM Sales at Petersen Manufacturing, “It’s not so much lighting failures that are causing problems. It’s premature system failures, which are more caused by corrosion than anything else. There are people getting citations everyday even with LED lighting systems. If they don’t have the right harness system behind it all they did was delay the failure.”

Randy Walker, director of North American aftermarket sales at Phillips Industries, agrees. He said, “Many of the equipment related CSA violations are attributed to failing lights or indicators on the trailer that receives its power from the tractor via the harness, socket and cable assembly. These components are exposed to the elements like road salts, moisture, rain, snow and chemicals used to melt snow like magnesium chloride, calcium or sodium chloride. This combination creates a perfect environment for corrosion to thrive, which severely limits the flow of current required to illuminate these lamps, which is an easy item for a DOT officer to spot, jeopardizing the truck driver’s and his employer’s CSA rating.”

Electrical system manufacturers, including Grote, Petersen and Phillips, offer harness systems designed to prevent corrosives from damaging a truck and trailer’s electrical supply system. For example, Phillips’ STA-DRY product line protects not only the fleet’s and driver’s CSA rating but the general public’s as a whole.

Air and electrical cords that are chaffed, cracked and rubbing or dragging on the deck plate are DOT violations that also become a CSA issue. Failing to secure brake hose/tubing against mechanical damage is a four-point CSA violation. Quality hose holders, tender spring kits and pogo sticks are all very useful cable support accessories that will help keep the hoses and cords off the deck plate. When well maintained and used correctly, they will help to prevent DOT and CSA issues and help the air and electrical cables behind the tractor last longer.

Tire condition is another condition that should generate little concern on the road assuming they are properly maintained. For tires, insufficient tread depth and under inflation are the most common problems found by roadside inspectors. No truck should ever leave a terminal with either of these conditions. It’s surprising that a driver would be willing to go on the road with either knowing if he is stopped he will get points as well as his company. A proper pre-trip inspection and follow-up would prevent both situations short of a nail picked up after leaving the terminal.

FMCSA certainly considers tire condition to be an important factor in road safety. Al Cohn, director of New Markets Development at Pressure Systems International, said, “In the CSA scoring system, tires can have a major impact. Tires have a score of eight or three depending on the specific issue. Examples include tires that are flat—less than 50% of the pressure indicated on the tire’s sidewall— are scored an eight along with tires below the minimum legal tread depth. A three-point penalty is assigned to tires that are underinflated. These points can add up especially when you consider that there are 18 or more tires on a typical Class 8 vehicle. Points also increase based on the interval since any previous similar penalty.”

Only a serious tire program will help assure that your CSA score is not adversely affected. Checking tire pressures on a regular basis in combination with automatic tire pressure monitoring and inflation systems can go a long way in keeping tire pressures at their recommended pressure. A check of tread depths across a tire’s tread surface should be done at every schedule PM.

“We are hearing from fleets running automatic tire inflation systems on their trailers that CVS people are not even bothering to check the tires because they know they will have the right pressure when they see a PSI tire inflation system hooked up and the hoses attached,” Cohn said.

Gary Ganaway is director of Marketing and Global Customer Solutions at Bendix Spicer Foundation Brake LLC. He said, “Brake problems are still running around 15%. The biggest issue is brakes out of adjustment, that is, the stroke exceeds the maximum limit. This situation, we believe, stems from misinformation regarding automatic slack adjusters. ASA’s are designed to maintain brake adjustment. If the fleet finds that it is necessary to adjust breaks, even on an occasional basis, it is an indication of a problem.”

One of the misconceptions brake manufacturers see is that slack adjusters have an infinite life. Like most mechanical devices, automatic slack adjusters have moving parts that wear out. When those parts wear out they need to be replaced. In the case of the automatic slack adjusters, an important indication is that they no longer hold brakes adjusted.

Bendix data indicates that when fleets find that a brake is out of adjustment, they adjust it to proper specifications and then they send the truck on its way. They need to understand that the slack adjuster might need to be replaced. That probably is not happening as often as we would like to see it.

Ganaway said, “Our recommendation to fleets is when they find a brake out of adjustment to take a look at the maintenance records to see when the automatic slack adjuster in question had been installed, and if that adjuster is at the three, four or five year range, it is probably time for that adjuster to be replaced.”

He went on to say, “The biggest thing with CSA is to not be afraid of it. Bendix wholeheartedly supports the efforts of CSA.”

Fleets that are interested in highway safety should follow that lead and consider NationaLease’s Stopka’s advice: “The biggest problems are caused by people’s inactivity. When PMs are being done properly, the truck will make it to the next PM.”