All indicators lead in the same direction. A 2013 report from the National Highway Traffic Safety Administration (NHTSA) says that under-inflation is the leading cause of tire failure. The Federal Motor Carrier Safety Administration (FMCSA) cites defective tires as a leading factor in crashes involving commercial vehicles. A 2010 Technology & Maintenance Council (TMC) report on tire pressure and inflation states that tires are the second leading cause of roadside inspection citations.

Today, increasingly stringent fuel economy standards for trucks are driving manufacturers to look for new ways to help improve MPG. According to the EPA, under-inflation of as little as 10 PSI can lead to a reduction in fuel economy between 0.5 and 1%.

“There are several ways for trailer manufacturers to achieve the new fuel economy targets,” says Matt Wilson, business unit manager for Hendrickson Controls. “Ultimately, trailer OEMs will need to decide which technologies will be required for compliance, but since automatic tire inflation systems are one of the technologies that are named in the proposed regulations, we expect that overall demand for tire inflation systems will increase.”

Beyond improving fuel economy, tire pressure optimization technology presents an opportunity for commercial vehicle fleets. Improper inflation also causes sidewalls to extend and contract, creating excessive heat and fatigue, accelerated tire wear and greater susceptibility to damage.

Increasing interest

Although those risks are well known, effective tire pressure inspection and maintenance can be a challenge. For drivers and fleet maintenance personnel, taking a pressure reading on every tire can be a lengthy process. It is no surprise that fleet managers are showing increased interest in tire pressure monitoring and inflation systems for trailers, as well as tractor systems.

Dana Holding Corp. is road testing a new tire pressure management technology for linehaul tractors. The internal axle system is engineered to automatically maintain proper inflation in tires on 6×4, 6×2 and 4×2 drive axle configurations and non-driven steer axles from multiple manufacturers.

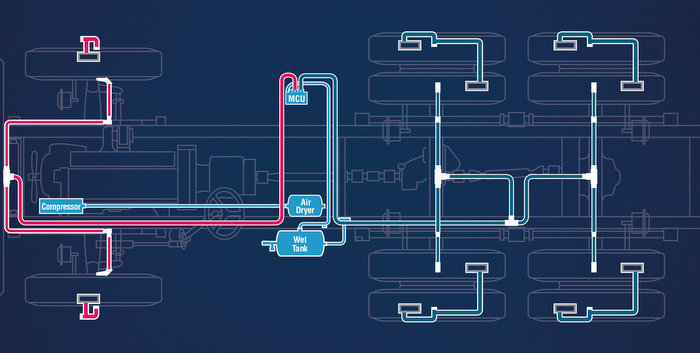

The Dana tire pressure management technology (as seen in the above photo) automatically initiates periodic system and pressure checks while driving, inflates tires as needed to optimum pressure and equalizes pressure in all tractor tires. The integrated system for OEM installation is compatible with J1587 and J1939 communications protocols so its electronic control unit can communicate tire inflation issues requiring immediate attention to a dashboard display. The steer-axle part of the system features a rotary joint with a cross-drilled spindle to supply air to the tires.

Future options may include a multi-channel system that can regulate up to eight wheel ends separately, as well as the ability to measure each tire’s internal air temperature.

The SmarTire Tire Pressure Monitoring System by Bendix Commercial Vehicle Systems has been added as a factory-installed option on Freightliner Cascadia and Cascadia Evolution models. SmarTire TPMS obtains temperature and pressure readings directly from inside tires and communicates wirelessly to an on-board receiver to provide real-time pressure and temperature data, along with alerts, via an in-vehicle display.

SmarTire TPMS also comes standard with trailer monitoring capabilities. Once the tractor is connected to a trailer equipped with the Bendix SmarTire Trailer-Link TPMS, trailer data will be automatically displayed in the tractor, monitoring all tires on a tractor-trailer combination. The system is also sold for retrofit in a kit that includes sensors, antennae, receiver, wiring and display.

Bendix is adding service options to SmarTire TPMS that will allow for sensor programming without the need to use of a separate sensor diagnostic tool. It is also providing ability to program a sensor by simply removing 5 PSI of air from the tire by using the system’s display.