Keeping a close eye on tire pressure can also impact your bottom line. Under-inflated tires flex excessively under load, producing heat and increasing rolling resistance, which wastes fuel. Tires inflated 10 PSI below recommended levels can reduce truck fuel economy up to 1%. In addition, stress from flexing causes fast and uneven wear, shortening the life of the tire. Let’s take a look at the tire pressure monitoring systems (TPMS) and inflation options that can keep your fleet rolling productively and safely.

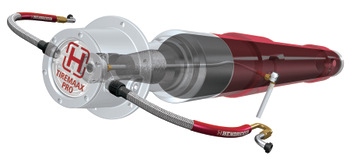

Hendrickson’s TIREMAAX automatic tire inflation system

Hendrickson’s TIREMAAX Automatic Tire Inflation System maintains proper inflation levels without pressurizing the axle or wheel-ends, said the manufacturer. The TIREMAAX system instead uses a rotary air connection that is integrated into the hubcap.

Hendrickson’s TIREMAAX Automatic Tire Inflation System maintains proper inflation levels without pressurizing the axle or wheel-ends, said the manufacturer. The TIREMAAX system instead uses a rotary air connection that is integrated into the hubcap.

“TIREMAAX CP features a simple mechanical design that comes factory-preset to a target cold tire pressure setting,” said Matt Wilson, business unit director—controls, Hendrickson Trailer Commercial Vehicle Systems. “The system monitors pressure in all tires and directs air to one or more tires when they dip below the preset level. A signal light activates only when attention is required.”

Wilson noted that TIREMAAX PRO is the company’s latest and best selling product. “PRO not only monitors and adjusts for low tire pressure, but also is designed to relieve air pressure when necessary to prevent over inflation and also equalizes the pressure across all wheel locations,” he said.

In order to keep the tires properly inflated, the PRO system draws air from the trailer air supply.

“If the ambient temperature increases, the system will relieve air when necessary to prevent over inflation,” Wilson said. “This feature is important to achieve maximum tread life with all tire configurations, but especially with tires that are sensitive to pressure like wide based singles.”

Wilson also noted that Hendrickson offers the only ATIS that pressurizes and balances tires.

“One of the benefits of TIREMAAX PRO is that the traditional manual tire checks are supplemented by the continuous monitoring of tire pressure. With TIREMAAX PRO, the driver is notified of low tire pressure almost immediately.

Of course, drivers need to make sure they are in compliance with any state and federal regulations for tire checks, but a labor savings can certainly be achieved by reducing, if not eliminating, manual tire checks by drivers, which can take an operator 30 minutes per rig,” Wilson explained.

Meritor Tire Inflation System (MITS) by P.S.I.

Meritor’s current inflation system, Meritor Tire Inflation System (M TIS) by P.S.I., harnesses a trailer’s existing air supply to keep tires fully inflated when the vehicle is in operation. Air from the trailer air supply is routed to a central control box and then into each axle. The axles act as conduits to carry air through a rotary union assembly, which distributes air to each tire as needed. John Morgan, senior product line manager of trailer products, reported that the MTIS system is spec’d on nearly one of every three trailers built today.

TIS) by P.S.I., harnesses a trailer’s existing air supply to keep tires fully inflated when the vehicle is in operation. Air from the trailer air supply is routed to a central control box and then into each axle. The axles act as conduits to carry air through a rotary union assembly, which distributes air to each tire as needed. John Morgan, senior product line manager of trailer products, reported that the MTIS system is spec’d on nearly one of every three trailers built today.

Meritor states that MTIS offers cost savings in tread wear, maintenance, fuel and tire downtime and replacement. This equates to, on average, $1,960 in savings annually per trailer, according to the company.

Additionally, the ThermALERT wheel-end heat-sensing technology option immediately alerts drivers to overheating wheel ends so that they can take preventive action to avoid damage. This increases vehicle, driver and public safety, and also reduces vehicle downtime, according to the company.

According to Meritor, maintenance is simple. “The standard system includes an indicator light that illuminates when the system is flowing air through the control box,” Morgan added. “Air flows only when the system is charging upon start-up, or when a leak is detected. If a leak should occur in a tire or anywhere in the system, the indicator light will illuminate, signaling the operator that service is needed.”

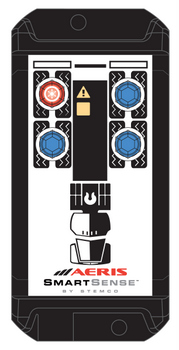

Stemco’s Aeris TPMS solution

Stemco’s Aeris TPMS solution

Similar to other automatic tire inflation systems (ATIS), Aeris by Stemco takes air pressure from the trailer brake system and uses it to inflate trailer tires. What sets Aeris apart, said Chris Steph, Stemco segment business leader, are three important features.

“The unique and patented rotary seal used in Aeris is designed to eliminate failures that can pressurize the wheel end and reduce maintenance by lasting up to millions of miles,” Steph said. “The Aeris system also utilizes a highly sensitive airflow detection system that not only detects and reports even minor inflation events, but can also generate a ‘high-flow’ warning, alerting the driver to serious tire issues so that he can pull over as soon as it is safe to do so. Aeris also includes hoses that are extremely robust and include filler/check ports at the wheel end.”

Stemco recently released Aeris SmartSense, an option that alerts the drive and maintenance personnel which wheel end is experiencing inflation due to leaks in the tire. “SmartSense significantly reduces the amount of time spend diagnosing which tire is taking air by narrowing the focus from eight tires down to two or four to one,” Steph noted.

The system offers reduced maintenance, a warranty up to seven years.

IPA Mobile Tire Pressure Equalizer

Minute discrepancies in tire pressure can have profound effects on both tread wear and fuel economy. The IPA Mobile Tire Equalizer provides a system which helps technicians perform consistent and accurate tire pressure maintenance across all fleet vehicles, the company reported. This saves tremendous amounts of money by improving fuel efficiency, reducing tread wear, spotting mismatched duals, and reducing blowouts.

Minute discrepancies in tire pressure can have profound effects on both tread wear and fuel economy. The IPA Mobile Tire Equalizer provides a system which helps technicians perform consistent and accurate tire pressure maintenance across all fleet vehicles, the company reported. This saves tremendous amounts of money by improving fuel efficiency, reducing tread wear, spotting mismatched duals, and reducing blowouts.

The IPA Mobile Tire Pressure Equalizer accurately reads and inflates tire pressure on multiple tires (up to five) at the same time. It is equipped with two integrated, high-capacity air regulators, and two accurate, high-resolution, glycerin- filled pressure gauges for consistent and precise tire pressure readings. Additionally, due to hands-free operation via lock on chucks, the Mobile Tire Pressure Equalizer promotes a safer work environment by placing the worker away from the tire during inflation.

Aperia Technologies Halo Tire Inflator

Aperia Technologies highlighted its Halo Tire Inflator is commercially available for use on drive and trailer axles on medium- and heavy-duty trucks and buses. Halo is an easy-to-install system that operates on a similar principle to a self-winding watch, the company explained. The device uses a wheel’s rotational motion to pump and maintain optimal tire pressure. The system does not require any connection to a compressor and can be installed in five to 10 minutes per wheel end.

Aperia Technologies highlighted its Halo Tire Inflator is commercially available for use on drive and trailer axles on medium- and heavy-duty trucks and buses. Halo is an easy-to-install system that operates on a similar principle to a self-winding watch, the company explained. The device uses a wheel’s rotational motion to pump and maintain optimal tire pressure. The system does not require any connection to a compressor and can be installed in five to 10 minutes per wheel end.

“The fuel savings from properly inflated tires are well documented,” said Josh Carter, CEO and co-founder of Aperia. Research by the Federal Motor Carrier Safety Administration (FMCSA) indicates that maintaining proper tire pressure results in a 1-2% fuel efficiency increase. 55% of all truck tires on the road today are at least 5 PSI from their target pressure, which also reduces tire life and increases annual tire costs by 10%-15%. Underinflation is also responsible for one blowout per tractor-trailer per year. Cater explains “numerous studies including research by the FMCSA show that by eliminating tire underinflation, the average fleet can save more than $2,200 annually for each tractor-trailer.”

Halo, an American Made product, is expected to operate effectively for 500,000 miles or 10 years.

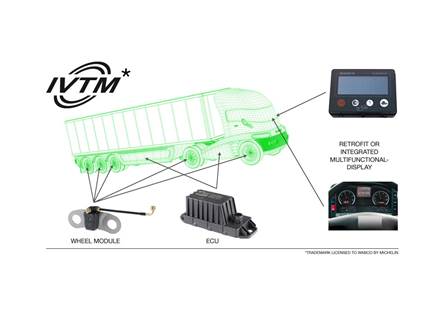

Wabco Integrated Vehicle Tire Pressure Monitoring

Wabco’s Integrated Vehicle Tire Pressure Monitoring system (IVTM) is especially developed for commercial vehicles. Wabco IVTM helps to ensure optimal tire pressure at all times to reduce fuel consumption and increase tire lifetime. It is a way to decrease fleet running costs while improving vehicle safety, according to the company. IVTM provides the driver with constant updates of tire pressures directly from each monitored wheel. Furthermore IVTM helps preventing tire blow-outs by timely informing the truck driver of a leak before the tire goes flat and is destroyed. In combination with TrailerGUARD telematics, IVTM also reports the tire pressures to a web portal and warns the fleet manager or dispatcher via SMS or e-mail.

Wabco’s Integrated Vehicle Tire Pressure Monitoring system (IVTM) is especially developed for commercial vehicles. Wabco IVTM helps to ensure optimal tire pressure at all times to reduce fuel consumption and increase tire lifetime. It is a way to decrease fleet running costs while improving vehicle safety, according to the company. IVTM provides the driver with constant updates of tire pressures directly from each monitored wheel. Furthermore IVTM helps preventing tire blow-outs by timely informing the truck driver of a leak before the tire goes flat and is destroyed. In combination with TrailerGUARD telematics, IVTM also reports the tire pressures to a web portal and warns the fleet manager or dispatcher via SMS or e-mail.

Mobile Awareness TireSTAT tire sensor

The Mobile Awareness TireSTAT Tire Sensor TPMS can be mounted internally or externally on the tire. The sensor transmits PSI and temperature readings every 60 seconds, 24/7 to both the Mobile TRAQ VUE in-cab Smart monitor, a touch screen portable computer that stores PSI and temperature information for one year, or the YardTRAQ PC application, a system that emails fleet managers to notify them of a low pressure tire. The sensor also features a 10-year battery life, which, the company says, allows for minimal maintenance.

The Mobile Awareness TireSTAT Tire Sensor TPMS can be mounted internally or externally on the tire. The sensor transmits PSI and temperature readings every 60 seconds, 24/7 to both the Mobile TRAQ VUE in-cab Smart monitor, a touch screen portable computer that stores PSI and temperature information for one year, or the YardTRAQ PC application, a system that emails fleet managers to notify them of a low pressure tire. The sensor also features a 10-year battery life, which, the company says, allows for minimal maintenance.

“Measurable cost savings are achieved through lower fuel consumption, reduced tire wear, fewer tire related ‘vehicle down’ roadside service calls and fewer customer penalties from missed appointments,” said Nico Cottone, chief operating officer and vice president of business development.

The company provides annual software updates with improvements and user requests for The Smart Monitor and PC Application. Tire sensors can be re-used from vehicle to vehicle without reprogramming as there are no special tools needed to add the sensors or cab monitor.

Continental TPMS solution

ContiPressureCheck is a direct measurement system glued to the inside of the tire that detects any changes in air pressure and air temperature. The sensor inside the tire sends the data wirelessly to the central control unit (CCU) to process the information. The CCU then uses this data to send warnings directly to the display in the driver’s cab. This allows the driver to take immediate corrective action and avoid a breakdown before it happens.

Continental feels that the positioning of the sensors on the inner liner of the tire protects it from hazards that can occur on the outside of the tire and damage that can result during the tire mount and dismount process.

“We tell customers that the cost of one tire-related roadside call will more than pay for our complete system when you consider lost time, a lost tire and of course the cost of the roadside call itself,” said Terry Smouter, business development manager, commercial vehicle tires, Continental.

Continental also recently upgraded the ContiPressureCheck system to allow a truck to connect to any trailer equipped with tire sensors. This is a critical advantage for fleets running drop and hook loads.

The system can be adapted to the demands of every fleet, the company reported. There are numerous possible configurations, including tractor and trailer—separate or together—since the sensor and receiver can be positioned in many different ways.

Dana Holding Corp. developing tire pressure system

Dana is developing optimized tire pressure system technology for linehaul tractors, the first integrated tire maintenance system of its kind for commercial vehicles, according to Tom Bosler, Dana Holding Corp. global director, product planning, who noted that while no official announcement has been made, systems are currently accumulating miles in the field.

“Currently undergoing road testing on commercial-vehicle tractors, this system has been engineered to automatically maintain proper inflation for drive and steer axles, significantly minimizing total cost of ownership through reduced maintenance, lower tire costs and maximized fuel efficiency,” Bosler explained. “As needed, the system inflates tires to the optimum pressure and can equalize pressure in all tractor tires, minimizing tire dragging and premature wear. A closed design isolates the tires, preventing a hose failure or tire puncture from affecting the other tires.”

Dana’s optimized tire pressure system technology can improve fuel economy by 1% by making periodic checks to ensure that each tire is properly inflated to a pressure equalized with the other tires on the tractor. Bosler provided an estimate of savings for a typical 6×4 linehaul truck logging 120,000 miles annually at today’s fuel prices involved in two tire event-related service calls per year at a total yearly savings of more than $1,500 from using the Dana system, noting that the total potential depends on numerous variables, including truck configuration, duty cycles, annual mileage and fuel prices.

Bendix SmarTire TPMS

Bendix Commercial Vehicle Systems (CVS) offers two TPMS products: SmarTire tire pressure monitoring system and SmarTire Trailer-Link TPMS. SmarTire TPMS monitors the pressure and temperature of each tire on a commercial vehicle to provide real-time tire status information to the driver or maintenance technician. The system reads pressure and temperature information directly from inside the tire and communicates wirelessly to an on-board receiver. The in-vehicle technology warns a driver of tire-related problems, including alerts for low tire pressure, extreme low tire pressure, and extreme high temperature—before they pose a safety hazard.

The company’s latest product is the SmarTire Trailer-Link TPMS, which wirelessly transmits alerts, pressure and temperature information for trailers directly to the tractor and is displayed on the SmarTire TPMS dash gauge or integrated vehicle cluster. It is now available to OE trailer manufacturers as an aftermarket retrofit kit. A typical kit consists of eight wheel sensors, harnessing and a wireless receiver.

IMI Tire air solutions

IMI offers several tire air pressure solutions. For a shop or service truck, there’s Air Auditor, an inflation system that automatically checks air pressures and inflates/deflates tires to fleet specifications. With mobile integration, Air Auditor also keeps a record of pressure measurements. The system provides alerts for significant or repeat pressure issues beyond the fleet specification.

IMI offers several tire air pressure solutions. For a shop or service truck, there’s Air Auditor, an inflation system that automatically checks air pressures and inflates/deflates tires to fleet specifications. With mobile integration, Air Auditor also keeps a record of pressure measurements. The system provides alerts for significant or repeat pressure issues beyond the fleet specification.

“Air Auditor’s ability to track and automatically inflate tires helps to reduce downtime associated with tire maintenance and reduces premature tire replacement costs,” said Derek Forney, IMI product marketing specialist.

The tool automatically records inflation measurements and correct tire pressures, allowing the fleet manager to focus on other maintenance areas. It provides accountability that each tire was checked for ideal preventative maintenance.

iTire, on the other hand, is a connected tire gauge, created to provide one-touch tire pressure measurement. The gauge is self-calibrating and impact resistant for use in any environment. Measurements may be taken through the gauge or TPMS unit and store in the unit or seamlessly uploaded to the cloud through a mobile device.

TireStamp’s TireVigil TPMS, TireVigil TPMS Trailer

TPMS Trailer systems monitor tire pressure and temperature, as well as vehicle location and tire and vehicle mileage. The systems’ telematics capabilities allow it to send tire and vehicle data from the vehicle to TireStamp where the data is analyzed, hot inflation pressure is converted to cold pressure and then compared to the fleet’s alert thresholds, and the data is stored.

Fleets are able to customize their own thresholds for alerts, receive standard and customized reports and set reminders for checking torque after a tire change and preventative maintenance based on mileage, among other features. “Since the data is stored in a database, useful reports can be generated not just on one tire or the tires on just one vehicle, but on all the tires at a specific yard location or in the entire fleet,” explained Peggy Fisher, president of TireStamp Inc. The system comes with three standard reports; an active issues report; service history report; and a fleet management survey that measures tire maintenance performance.

Balancing beads

Counteract Balancing Beads provide an automatic, readjusting, trouble-free balance of the complete wheel assembly, in all wheel positions, for the life of the tire. Tests run by Auburn University’s Program for Advance Vehicle Evaluation (PAVE) resulted in a 2.2% improvement in fuel economy. Counteract is the only balancing method in the world to have conclusively proven better fuel economy. Completely trouble free, dust free and simple to use, the Counteract “bag in bag” system makes it easy to install. Throw the inner bag into the tire before mounting it. Counteract can also be injected through the valve stem. All wheel assemblies on the vehicle must be balanced to achieve maximum gains in fuel economy, increased tire life and reduced vibrations.

Counteract Balancing Beads provide an automatic, readjusting, trouble-free balance of the complete wheel assembly, in all wheel positions, for the life of the tire. Tests run by Auburn University’s Program for Advance Vehicle Evaluation (PAVE) resulted in a 2.2% improvement in fuel economy. Counteract is the only balancing method in the world to have conclusively proven better fuel economy. Completely trouble free, dust free and simple to use, the Counteract “bag in bag” system makes it easy to install. Throw the inner bag into the tire before mounting it. Counteract can also be injected through the valve stem. All wheel assemblies on the vehicle must be balanced to achieve maximum gains in fuel economy, increased tire life and reduced vibrations.

The Federal University of Brazil recently reconfirmed test results from Auburn, proving that tires run cooler, last longer and save fuel, doubly proven in the PAVE and TMC SAE Type II tests.

Other benefits include improved handling, reduced wear and tear on the vehicle and freight due to reduced vibrations. Counteract is reusable and recyclable, making it the environmentally friendly choice for balancing. Test results along with testimonials are available here.