“Traditionally, there has been an understanding in the industry that excellent drivers develop skill sets to operate equipment in a way that generates good fuel mileage,” says Mario Sanchez, technical sales support director at Cummins. “Even the best drivers are not consistent all the time, however, and as fleets continue to struggle to retain and attract a skillful driver force, integrated powertrain technology helps all drivers operate more efficiently.”

Automated transmissions and engines sharing data provide consistent results day in and day out, Sanchez notes. “With these integrated systems, fleets do not have to worry as much about whether drivers will operate as efficiently,” he states. “These solutions allow fleets and drivers to pay more attention to improving other factors related to profitability and productivity.”

There is a compounding effect from engine-transmission integration, Sanchez points out. “With engines running at a lower RPM, there is not only less fuel use but also less friction and therefore less heat, which improves long term durability,” he relates. “Also, providing only the torque required and automating gear changes optimizes the powertrain for fuel economy.”

Another benefit of integrated powertrains, and something that became even more visible during this past winter’s extreme cold conditions, was the lessened potential for damage to drivelines. “New engines can produce higher levels of torque,” Sanchez explains. “Integrated powertrains determine the best torque level, reducing damage to drivelines, tires and wheel end components, especially during cold weather.”

Smarter and smoother

Eaton’s Director of Medium and Heavy Transmissions Worldwide Jeffrey Walker says that the capability to provide torque matched to mass and grade, and choosing the optimal gear for operating conditions automatically can extend driveline life and provide a measurable fuel economy benefit. “We’ve seen much better fuel economy—three to six percent better on average and some higher results,” he states, “due to smarter acceleration and smoother shifts.”

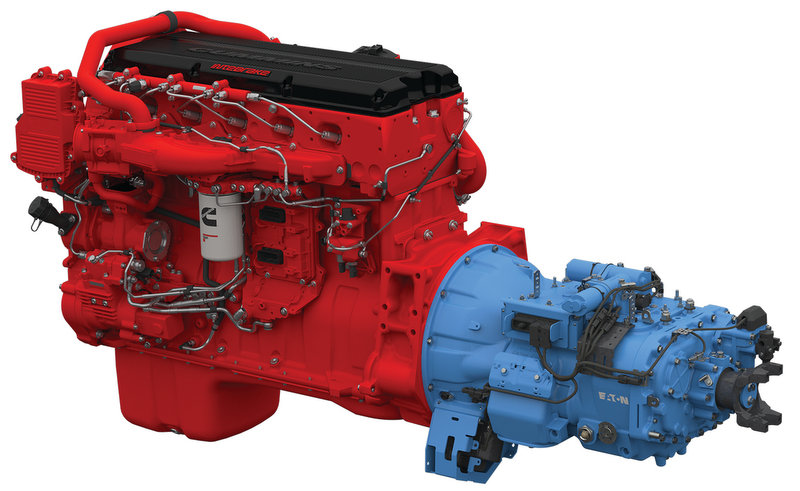

Eaton and Cummins now offer an expanded line of SmartAdvantage Powertrain packages that includes applications for Cummins ISX12 and ISX15 diesel engines. The product line initially integrated an Eaton Fuller Advantage Series Automated Transmission with the Cummins ISX15 engine.

The newest SmartAdvantage offering will pair the Eaton Fuller Advantage Series 10-speed Automated Manual Transmission with the Cummins ISX12 engine. It will be offered as a small-ratio-step overdrive model with two new Cummins ISX12 SmartTorque2 (ST2) ratings: The ISX12 370ST2, with torque of 1,150 lb./ft. to 1,450 lb./ft., and the ISX12 425ST2, with torque of 1,350 lb./ft. to 1,650 lb./ft.

“These integrated powertrain offerings combine two proven and innovative technologies,” Walker states. “Integrated, highly engineered components reflect a depth of knowledge from innovative focused companies. This is clearly a case where one plus one equals more than two.”

New offering

Internal development efforts at Daimler Trucks North America (DTNA) have led to the integrated Detroit Powertrain, featuring a Detroit DD15 engine, Detroit DT12 transmission and Detroit axles. The new offering will be available starting in January 2015 in the Freightliner Cascadia Evolution and later in 2015 for the new Western Star 5700.

“When technologies come from a single supplier, it makes working relationships easier and you have better results from consulting on issues and challenges,” says Brad Williamson, manager, engine and components marketing. “With engineers who are all on the same team, there is a focus on communication and you have integrated powertrain components and vehicles that are all speaking the same language.”

The integrated Detroit Powertrain features a new axle ratio and configuration to match the DD15 engine’s “downsped” rating of 400 HP and 1,750 lb./ft. of torque. Engineers also tuned the transmission electronics, and the integrated DT12 automated manual transmission in the offering has a new Intelligent Powertrain Management (IPM) function that uses pre-loaded terrain maps and GPS to know the route ahead and automatically adjust transmission and engine functions.

“The downsped rating enables the engine to turn at a lower RPM regardless of road speed, reducing fuel consumption and friction, while delivering necessary torque,” Williamson says. “Downspeeding technology improves fuel economy by shifting usable power and torque to a lower RPM range. Fuel economy, which is a bottom line deliverable, can improve from five to seven percent with the Detroit Powertrain depending on axle configuration.”

One roof

Roy Horton, director of segmentation management at Mack Trucks, says that having produced its own engines, transmissions and axles for much of its history, the OEM has learned quite a bit about powertrain integration. “Everything we have accomplished is the result of designing, developing, testing and optimizing integrated powertrains under one roof,” he states.

Tailored to meet different application needs, Mack integrated powertrain offerings include the 11-liter MP7 engine rated from 325 to 405 HP, the 13-liter MP8 engine with a range from 415 to 505 HP and the 16-liter MP10 engine from 515 to 605 HP. Each engine, which can be specified for torque and power needs to maximize efficiency, can be mated to the Mack mDRIVE 12-speed automated manual transmission built exclusively for Pinnacle tractors and two different axle configurations.

“It’s about optimizing performance,” Horton states. “Along with fuel efficiency, completely integrated powertrains offer other tangible benefits, including the ability to enhance warranty, parts availability and service capabilities to better meet fleet needs.”

Integrated powertrains are described by suppliers as the perfect marriage, one that produces fuel cost reduction and driver retention benefits for fleets, as well as fosters compliance with greenhouse gas emissions and MPG mandates for manufacturers.

The integration of powertrain technologies, they say, helps balance the equation on all fronts, and the further the industry moves down the path of integration, the better the solutions it will be able to provide to help lower cost of ownership.

Proving value

Last fall, FPInnovations’ Performance Innovation Transport (PIT) group, a not-for-profit engineering and research group for the North American trucking industry, began conducting fuel consumption tests comparing 2014 model year European and North American Volvo Trucks models with fully integrated powertrains. The equipment, leased by Transport Robert, a Boucherville, Québec-based truckload, LTL, intermodal and specialized carrier that serves customers across the United States and Canada, was evaluated at the Transport Canada Motor Vehicle Test Centre in Blainville, Québec.

The PIT group evaluated fuel efficiency on the Volvo tractors using the SAE J1526 Type III fuel consumption procedure, which compares vehicles using the gravimetric method of weighing portable tanks before and after each trip. The tractors for comparison are switched between trailers at mid-test. Values for fuel savings will be released in the future.

“The first question is always about fuel efficiency,” Provencher says, “but fleets are also interested in knowing about reliability and maintenance issues. From what we’ve seen, with integrated powertrains that are developed by manufacturers talking to each other, it can be easier to connect engines and transmissions.”

The PIT group has also produced test results on a key component of integrated powertrains. Its evaluation compared the fuel consumption of automated manual and automatic transmissions. “Our fuel consumption tests found that automated manual and automatic transmissions have the potential to improve fuel efficiency when compared to manual transmissions,” Provencher reports. “These tests have also shown that the driver still plays a role in fuel consumption. Therefore, to optimize fuel efficiency, efficient driving techniques must be used. Additionally, the driver shortage has meant some fleets have to hire and train less experienced drivers. Automated manual and automatic transmissions will help those drivers obtain decent fuel economy faster.”

“The goal of these trials, like all evaluations by the PIT group, is to use our controlled test-track fuel efficiency studies to provide the commercial vehicle industry with the information it needs to make sound equipment choices,” Provencher continues. “By providing our fleet members with accurate results on the return on investment they can expect, they can make more effective capital investments. Our fuel efficiency evaluation procedures include the most stringent testing protocols and guarantee independent verification of a technology’s fuel efficiency performance. The result is a fuel savings projection that is highly representative of what a fleet can expect to realize in actual service.”

Benefits for U.S. and Canadian fleet members of the PIT group include the ability to choose which new technologies and operational practices are submitted for fuel efficiency testing, access to past test results on fuel efficiency of different technologies, and access to the group’s engineering resources and peer networking opportunities for fleet owners and managers.

“Leveraging the disciplined PIT testing protocols allows member carriers to focus our efforts on core competencies, including managing our fleet operations,” said Chris Trajkovski, vice president of fleet maintenance at Bison Transport. “Without internal engineering expertise, fleets cannot effectively determine the merits or quantify the net impact of fuel efficiency technology claims on fleet performance.”