As fleets continue to seek new technology that lowers their overall total cost of ownership (TCO) while improving safety and performance, notes Bill Hicks, director of product planning/market development for the Trailer Suspension Business Unit at SAF-Holland, suspension/axle suppliers are responding with a total system integration approach. “This presents opportunities for matching and optimizing the complete suspension, axle, brakes and wheel end components to provide maximum performance and value while reducing overall weight,” he says.

Chris Farrar, truck vocational marketing at Hendrickson, agrees about the latest trends in axle and suspension design. “Suspension, axle and brake system suppliers are partnering with vehicle builders,” he states. “Whether the products are branded by the manufacturer or are proprietary to the OEM, integrating components from a single suspension, axle and wheel end supplier makes it easier for customers, especially when it comes to parts and service needs.”

Pending fuel economy and greenhouse gas standards under development by the U.S. Environmental Protection Agency (EPA) and the Department of Transportation for medium-duty and heavy-duty vehicles by March 2016 are also impacting axle and suspension system design. “The announcement increased pressure on truck manufacturers to accelerate their efforts to squeeze more miles out of every gallon,” relates Andy Nieman, vice president of global engineering for Dana Commercial Vehicle Technologies. “Every vehicle system is ripe for scrutiny.”

The answer, Nieman notes, is engine downspeeding, a reduction in RPM from around 1,450 to a more efficient range, generally 1,100 to 1,200 RPM while maintaining horsepower at the wheel end. “As a result,” he says, “fuel efficiency will increase substantially but for every 100 RPM drop in engine speed, torque goes up significantly to maintain full power.

Added stress

In a white paper on the subject, Nieman goes on to explain that an engine running at lower RPM requires faster axle ratios to maintain the same vehicle speed and performance in all driving conditions, and that generates higher torque stresses in the drivetrain. “By decreasing an engine’s RPM at cruise speed from 1,450 to 1,125 for a downsped engine,” he explains, “torque loads in the driveline increase by 5%. These higher torques place added stress on the axle and demonstrate the need for suppliers to properly address the increase in torque.”

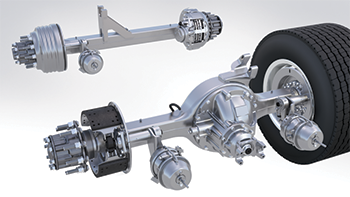

Approaches for handling the increased drivetrain torque with downsped engines include a systems approach that addresses the high-cycle fatigue that results from long-term stresses. “This solution requires an axle and driveshaft system engineered from the start to work together to support engine downspeeding,” Nieman states. “It includes an efficient, lighter weight tandem axle that offers the fast ratios required and that can withstand higher torques.”

The Dana system optimized for engine downspeeding includes the Spicer AdvanTEK 40 tandem axle, which is offered in five faster axle ratios to handle the higher axle input torques that result from lowering engine RPM at highway cruise speeds. Dana is also collaborating with truck manufacturers to engineer axle disconnect technology that will accommodate even further engine downspeeding to the 900 RPM range.

Portfolio launch

Beginning this year, Meritor will launch a portfolio of products that it says supports demand for improved fuel economy through downspeeding of engines. In particular, the manufacturer will offer a 2.28 ratio on its 14X tandem for 6×4 linehaul applications and a 2.31 ratio on its new FUELite+ tandem for the 6×2 market.

“This comprehensive approach to downspeeding ensures torque is transmitted evenly throughout the drivetrain without stressing any particular component and compromising reliability,” says Karl Mayer, product line director, rear axles for Meritor. “The new axle ratios are perfectly suited to accommodate the current industry trend toward downspeeding.”

Improving fuel economy and reducing maintenance are among the trends in axles and suspensions, says TJ Thomas, director of marketing and customer solutions, Controls group at Bendix Commercial Vehicle Systems, and along with weight savings to help boost hauling capacity, are the reasons fleets might look at automatic lift axle controls on 6×2 axles.

Available from Bendix as an add-on to its ABS-6 braking system with Automatic Traction Control is eTrac, an automated air pressure transfer system for 6×2 tractors and trucks. eTrac automatically engages and disengages the vehicle’s airbag pressure transfer system during low-traction events, transferring pressure from the undriven axle to the driven axle without requiring driver input.

“By automating the air transfer process, the eTrac system makes it easier for fleets to take advantage of the more efficient suspensions typically found on 6×2 tractors,” Thomas states. “Unlike a manual system, eTrac can respond in fractions of a second to a low-traction situation, offering real-time adjustment. eTrac also provides protection against drivetrain damage by automatically disengaging after a low-traction event or when the vehicle’s speed exceeds 25 MPH.

Bendix has also enhanced its TABS-6 Advanced trailer roll stability system with automatic lift axle control. When equipped on a trailer with a lift axle, TABS-6 Advanced monitors the load on the air bags and based on the trailer’s suspension capacity and legal load limits will raise or lower the axle as required without driver input. Automatic lift axle control is customizable and can be set to lower the axle automatically when the trailer is parked so when the trailer is loaded it is ready to handle its weight capacity.

Versatility

Paula Ngo, marketing coordinator at Hendrickson Truck Commercial Vehicle Systems, says that in addition to providing fuel and weight efficiencies, a 6×2 configuration such as Hendrickson’s OPTIMAAX system also offers versatility through its liftable axle.

“With OPTIMAAX, the integrated lift axle, suspension and controls are installed in the pusher position, allowing the tractor to operate in both 6×2 and 4×2 configurations,” Ngo explains. “The lifted axle position provides increased traction by increasing drive axle load, which offers a distinct advantage over traditional 6×2 tag systems when backing under trailers in soft soil or wet conditions, and driver intervention is not necessary due to the system’s fully automated load-sensing controls for axle lowering and lifting.

“In addition to the 2.5 to 3% fuel economy savings achieved by 6×2 systems,” Ngo adds, “OPTIMAAX can achieve an additional 2 percent in fuel savings when it operates in its lifted position, yielding up to a 5% fuel economy improvement and a weight savings over 6×4 configurations. The system’s capabilities address the operational needs of variable load carriers such as bulk haulers and other applications experiencing empty backhauls.”

Jason Heath, product manager, powered vehicle systems at SAF-Holland, notes how the use of 6×2 axles and suspensions is becoming more popular. “6x2s offer significantly improved fuel economy versus traditional 6x4s,” he states. “Additionally, 6x2s now benefit from electronic stability control and automatic axle lifting/load regulating technologies that help improve traction. 6×2 products have also been weight reduced substantially.”

SAF-Holland truck suspension products for vocational applications include the 13,500-lb. capacity Neway LSZ auxiliary steerable lift axle. “With lift axles, small is a big deal,” Heath says. “Space has become a precious commodity on chassis due to the requirements for diesel exhaust fluid (DEF) tanks and larger exhaust systems. Even when there is enough space for a traditional lift axle, a shorter one is preferred to give body builders more space for additional equipment.”

Increased capacity

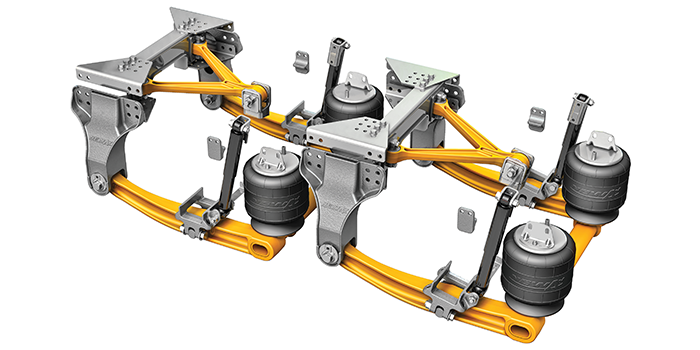

On the trailer side, of SAF-Holland’s business, the company has expanded its CBX Series Air Suspension/Slider Axle System for the North American market. Included is the SAF CBX46, a 46,000-lb. capacity system that features a new trailing arm designed to handle increased duty cycle and axle capacity demands for moderate- to heavy van and reefer applications. Also new is the 50,000-lb. capacity SAF CBX50 air suspension slider axle system, which is also approved for the Mexican market. This spring, SAF-Holland will also be introducing its ULX40 mechanical trailer slider suspension system.

Ridewell Suspensions is adding a new series of trailer suspensions to its RSS-233 product line. The 13,200-lb. capacity suspensions designed to reduce weight include a compact mounting envelope and an adjustable hanger system, and ship fully assembled to simplify installation. The 233 series steerable liftable suspensions are available in a range of ride heights.

Also launched by Ridewell is the RAR-266 Series trailer air ride suspension. The completely new product features a 5-3/4-in. large diameter axle and is available initially in narrow and wide pivot bushing models as well as 23,000- and 25,000-lb. capacities.