Winter-proof: How to keep your trailers in the best possible shape during the harshest season

There’s plenty to like about the winter, but it’s not all skiing and hot chocolate, especially if you’re a fleet manager who has to worry about the damage the harsh season will cause your equipment. Let’s zero in on trailers, which are susceptible to a variety of potential issues when running during the winter. Luckily,

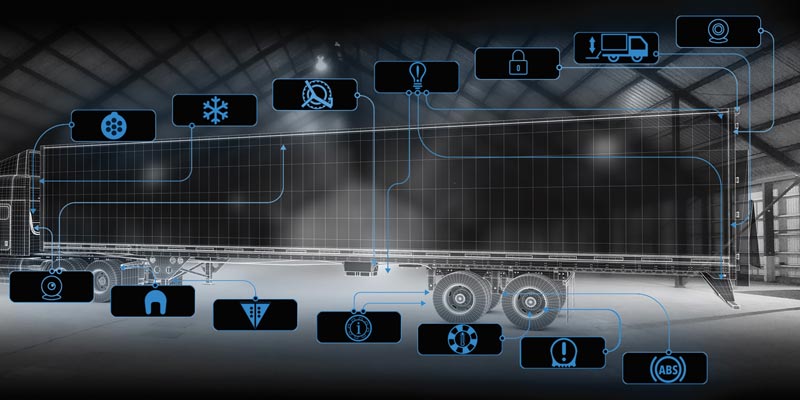

How implementing trailer tracking systems can streamline operations

With industry challenges such as driver shortages and high levels of equipment utilization, efficiently managing trailers is more critical than ever.

How trailer manufacturers are combating corrosion

Among trailer manufacturers, there is an ongoing effort to address costly corrosion and moisture intrusion. At Great Dane, approaches to combat corrosion include replacing corrosive metal with non-corrosive composite materials and applying coating systems on the metal components, according to Chris Lee, vice president of engineering. “Great Dane’s EnduroGuard rear frame uses stainless and galvaneal

Utility introduces new aerodynamic device

Utility Trailer Manufacturing Co. has introduced the Utility Aerodynamic Tail (UAT). When paired with low rolling resistant tires and configured on a Utility dry van or reefer, the combination of the Utility-designed Aerodynamic Tail and Side Skirt are designed to reduce fuel use and aerodynamic drag, the company says. The Utility Aerodynamic Tail was engineered

Fighting moisture intrusion in refrigerated trailers

“Moisture intrusion in refrigerated trailers impacts thermal performance through the degradation of insulating foam quality, increases in thermal conductivity and potential weight gain,” says Chris Lee, vice president of engineering at Great Dane Trailers. “Outgassing, in particular, causes moisture intrusion into foam cells, degrading the insulation’s value and leading to as much as a 30%

Mid-States Utility Trailer Sales opens new Iowa facility

Mid-States Utility Trailer Sales has opened a new facility in Sioux City, Iowa, 8 miles south of its existing location, Utility Trailer Manufacturing Co. announced. “We are excited to grow in Sioux City,” said Shane Keizer, president of Mid-States Utility Trailer Sales. “We decided to build in a location that will offer a better experience

Buying used trailers: What to look for and ask about

The current freight environment is booming and remains favorable for carriers. New dry van trailer builds, however, are booked nearly through the end of the year, which presents a challenge for growing fleets that want to add hauling equipment to their arsenal. Outside of tightening up your operational efficiency, buying a used dry van trailer

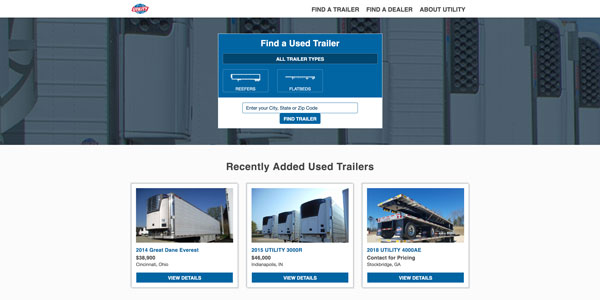

Utility launches used trailer website

Utility Trailer Manufacturing Co. has launched a new website featuring its available inventory of used trailers. “The new Utility used trailer website will serve as a valuable tool to our worldwide dealer network, customers and wholesalers,” said John Morrison, national used trailer manager for Utility Trailer Manufacturing Co. “This one-stop shop allows customers to view

Utility unveils 4000AE Drop Deck Flatbed

Utility Trailer Manufacturing Co. has introduced its 4000AE Drop Deck flatbed trailer. “Our new 4000AE Drop Deck incorporates the advanced technology that is found in our 4000AE combo flatbed, delivering the long-term benefits of both steel and aluminum,” said Brett Olsen, marketing manager for Utility. “In fact, a customer will discover that it weighs less

Utility Trailer manufacturing plant recognized with Liberty Mutual safety award

Utility Trailer Manufacturing Co.’s Paragould, Ark. manufacturing plant has received the Liberty Mutual Insurance Safety Commendation Award. Liberty Mutual’s Safety Awards are based on the days away, restricted and transferred (DART) rate, which is calculated from the number of hours worked relative to the number of accidents at the plant. A lower number of accidents results