When it comes to irregular wear and ride quality, tire/wheel assembly run-out and balance is an important issue for fleets. Removing expensive commercial tires prematurely, due to the early onset of tire irregular wear, will have a significant negative impact to the fleet’s bottom line. Tire and wheel manufacturers recommend balancing, but it is up to the fleet to determine what is best for their specific operation. Troubleshooting ride complaints is solved in many cases by balancing the tire/wheel assembly.

There are two types of run-out related to tire/wheel assemblies. Radial run-out is best thought of as tire “hop.” For a tire or wheel, its effect is to raise and lower the vehicle as it rolls along. This gives the perception of a hop or bounce. It is usually described as wheel “out of round.” These conditions are caused by non-uniformity in the tire/wheel assembly and the axle end. Radial run-out leads to irregular wear.

Lateral runout is tire “wobble,” which leads to ride vibration and poor ride quality. It can be described as a side-to-side movement of the rotating assembly. For the tire or wheel, its effect is to lead the vehicle alternatively right and left as it rolls down the highway. Drivers can easily feel the ride vibration and will not be very happy.

Some fleets check run-out on steer tire wheel assemblies; other fleets have found that checking run-out on all tire wheel positions maximizes tire removal mileage and eliminates driver vibration complaints.

So what is the proper procedure to check both radial and lateral runout? Tires will begin to show signs of flat-spotting after 15 minutes of sitting still. Therefore, check run-out as soon as possible after the vehicle has stopped. Use a tire run-out gauge or dial indicator to check radial and lateral run-out.

Check the radial run-out of the rotating tire-wheel assembly at the center of the tread, preferably on a smooth rib. Check the lateral run-out in the center of the sidewall.

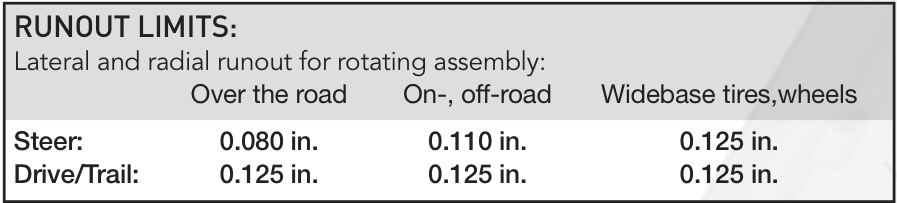

If total radial run-out exceeds the limits listed in the table, deflate the tire and unseat the beats. Lubricate the rim and rotate the tire 180º on the rim. Then re-inflate the tire and recheck radial run-out.

If lateral run-out is too high, remove the wheel, clean the mating surfaces, reinstall the wheel, and then check the lateral run-out.

A tire/wheel assembly that is out-of-balance is the result of an unequal distribution of weight about the axis of rotation. As with run-out, assemblies which are out-of-balance will lead to premature tire removals due to irregular wear. Vibration may also occur.

Tires will begin to show signs of flat-spotting after 15 minutes of sitting still; therefore, check run-out as soon as possible after stopping the vehicle.

A tire/wheel assembly can be balanced externally in two ways, static or dynamic. If the tire/wheel assembly is statically out-of-balance, the rotating tire will “bounce.” Adding wheel weights at the low spot and split between opposite sides of the rim flanges will get the assembly back in static balance.

When the assembly is dynamically out of balance, the rotating assembly will “wobble.” If the rotating tire/wheel is dynamically balanced it also will be statically balanced. The opposite is not true. A statically balanced tire may not be dynamically balanced.

A third option to balance tire/wheel assemblies is to use a material that moves inside the tire as the assembly rotates. These materials may reduce vibrations including road shock inputs at the axle end. A fourth option is balance rings, which are devices that have a material enclosed in a ring that rotates as the vehicle runs down the highway. They are mounted between the brake drum/hub and the wheel. The idea is to eliminate imbalance as the vehicle moves by constantly balancing the axle end through the movement of the material in the ring.

Keeping tire/wheel assemblies balanced, along with maintaining radial and lateral runout maximum specifications, will help reduce irregular wear and driver vibration complaints.

An excellent detailed source of tire/wheel end balance and run-out information is Recommended Practice 214D from TMC.