A major initiative in the trucking industry continues to be the concept of downspeeding, or maximizing available engine torque while minimizing engine RPMs and fuel requirements.

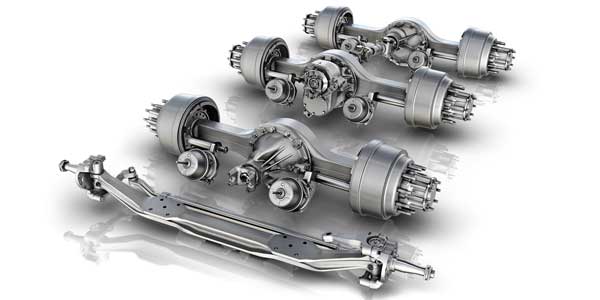

“By focusing on maximizing downspeeding, the fleet owner has the best chance of improving fuel efficiency,” explains Tom Lehman, product manager for Detroit Components. “Along with Detroit DD15 or DD13 engines and Detroit DT12 automated manual transmissions, Detroit rear axles and rear axle ratios are specifically designed to support downspeeding functionality. Detroit rear axles can be ordered with specific faster rear axle ratios depending on whether the fleet favors direct drive or over drive transmissions.”

In the 2018 Freightliner new Cascadia, which is now in production, the available combinations are a 2.28 or 2.16 rear axle ratio with a Detroit DT12 Direct Drive transmission or a 2.85 rear axle ratio combined with a Detroit DT12 Over Drive transmission. In addition to the even faster axle ratios, the Detroit rear axles are available exclusively in the new Freightliner Cascadia with an optional Axle Lubrication Management (ALM) system, which regulates the oil level at the ring gear through the use of a valve integrated into the ring gear cover which reduces the “churning” associated with the ring gear moving through the oil. This reduction in parasitic loss helps to realize even greater fuel economy gains, Lehman points out.

RELATED: Watch our video on the new Freightliner Cascadia here.

Engine ratings and transmission specifications have a major impact in configuring the correct axle/axle ratio combination. “Every spec is a relationship of fuel economy and performance attributes,” Lehman says. “In general, anything a fleet customer does with a spec to improve fuel economy will reduce performance and vice versa. Suggesting that a fleet moves to faster axle ratios [lower axle ratio numbers] will most likely improve fuel economy but reduces the mechanical advantage of the drivetrain; thus, performance can be reduced.”

Detroit offsets this degradation by increasing the torque output of the engine while at the same time reshaping the torque curve to produce greatest torque at lower engine RPMs, where the gearing will cause the engine to engage in a timely manner to support downspeeding.

Loads and specs

When it comes to handling maximum, constant and/or diminishing loads, axle spec choices can be influenced by the amount of time spent in each load situation. “Again, start ability and grade ability come into play when discussing load situations,” Lehman says. “More time in a maximum load situation may impact start ability and grade ability to a greater degree than if the majority of time is spent in a constant load or diminished load situation. Depending whether the fleet customer is more fuel conscious than anything else can drive how they might spec their Detroit rear axles and rear axle ratios.”

Meritor Product Manager Eric Lewandowski says that achieving better fuel economy through axle specs and axle ratio configurations.

“It really depends on the type of fleet and what they haul and the terrain that they travel,” he explains. “A direct transmission paired with a fast ratio like a 2.28 may be perfect for fuel savings. But if the fleet travels in the mountains at all or uses the truck less than 80-85% linehaul in top two gears, then the 2.28 may not be ideal and actually hurt the fuel economy of the fleet.

“An overdrive ratio like a 3.42 or 3.08 may give the same fuel savings as a direct drive in the top two gears and not have to worry about startability or gradeability,” Lewandowski continues. “But you have the extra gearing in the transmission, which does not save on efficiency. There are other factors within the truck spec that can make the best combination as well but these would need to be reviewed by the OEM.”

As for engine ratings for HP and torque, and transmission specifications affecting choices for axle configurations and ratios, Lewandowski says, “Some of the axle ratios have certain ratings that they can handle. Sometimes this can be handled by torque management in the engine and transmission. The effect of maximum, constant and/or diminishing loads affect axle specs depends on the fleet is running a tandem or a single axle and what type of engine and transmission and load that they are carrying. Some fleets run a 4×2 setup with our RS23186 which has a 19.62-in. ring gear where other fleets run a RS23160 with a 18-in. ring gear. Meritor has an applications group by OEM and a sales and service representatives [driveforce] for each state that can sit down with the fleet/dealer and determine, based on what the fleet hauls, what the best solution is for the fleet to achieve the best fuel economy.”

A combination of factors

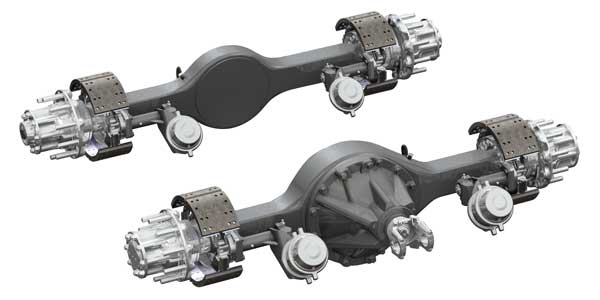

“In most cases, maximizing fuel economy improvement comes from a combination of factors, all of which are dependent upon the specific needs of a particular fleet,” begins Steve Slesinski, director of product planning for the commercial vehicle market at Dana Inc. “First and foremost, fleet owners should thoroughly evaluate route characteristics, payload demands, and resale plans to determine a drivetrain system that best serves their needs. Slower [numerically higher] axle ratios traditionally provide better performance, but at the expense of fuel economy. Faster [numerically lower] axle ratios allow the engine to operate more efficiently, and a range of technologies exists to help fleets find a balance between efficiency and performance. The axle and ratio should match the truck’s performance requirements for the intended application.”

Regardless of the ratio, axles can vary in efficiency. Depending on design and mechanics, all axles are not created equal.

“Dana offers a range of Spicer axles featuring AdvanTek gearing with greater power density delivered by our ring and pinion gear sets, and other innovative axle design features to maximize performance, reliability, and efficiency,” Slesinski says. The axle configuration type also offers varied levels of efficiency. A 6×2 tandem axle can offer weight savings to drivers operating in situations where torque to all four-wheel ends is not critical. Featuring one rear drive axle along with either a tag or pusher “dead axle,” this configuration can deliver two to three percent more efficiency than a traditional 6×4 arrangement.

Dana is offering for 6×2 configurations is the Spicer EconoTrek tandem axle. Available in 21 different ratios for vehicles with a gross combination weight (GCW) of up to 125,000 lbs., it delivers up to 350 lbs. of weight savings and offers numerous innovations for reducing maintenance, according to the company. In combination with electronic-controlled air suspension systems, a 6×2 tandem axle with a differential lock can alleviate many traction concerns. For example, the Bendix eTrac system seamlessly transfers weight to the drive axle for improved low-speed traction, according to the company.

“While fuel economy is important, performance and reliability are also essential for maximizing vehicle uptime,” Slesinski adds. “For drivers traveling long distances with a full load, a 6×4 axle configuration provides maximum traction, offering a balance of robustness and efficiency. Faster axle ratios typically result in better fuel economy. However, that ratio must lower engine RPM while the vehicle operates at highway cruise speeds without compromising performance. The Spicer AdvanTek 40 tandem axle was designed with faster axle ratios to handle the higher axle input torque that results from this engine downspeeding strategy. Dana leads the industry with seven available ratios to support engine downspeeding, ranging from 2.26:1 to 2.93:1.”

Transmission choices

The selection of engine and transmission combinations determines the torque required to deliver an optimum power level. Specifying the optimum axle size and driveshaft to handle torque loads is important.

“Dana offers a range of robust, lightweight driveshaft solutions to fit specific commercial-vehicle applications.” Slesinski says. “The SPL 350 driveshaft and the next-generation SPL 350 Lite driveshaft handle 30% higher input torque from downsped powertrains, enabling increased overall vehicle efficiency while maintaining expected reliability and life with direct drive transmissions. The SPL 350 Lite version is also 30 lbs. lighter, pushing efficiency even further in applications for axle ratios 2.5:1 and numerically lower. Better fuel efficiency can also be achieved with slightly higher axle ratios through overdrive transmissions. The SmartAdvantage powertrain offers fleets the choice of a small-step overdrive transmission that delivers exceptional fuel economy in less-than-truckload [LTL] and regional linehaul operations.”

The terrain factor

Start-ability and grade-ability related to the terrain of the routes a fleet covers are two of the most important factors in selecting a rear axle ratio. The amount of time that will be spent in severe terrain is a critical consideration of the rear axle ratio spec.

“To a lesser extent, traction may be a consideration in choosing an axle configuration and is not as focused on the rear axle ratio spec,” Detroit’s Lehman says. “Choosing a 6×4 or 6×2 rear axle configuration can be impacted by terrain considerations. In general, a 6×4 rear axle configuration offers better traction in certain terrain conditions. By pairing the Detroit axles and rear axle ratios with the Detroit DT12 featuring Intelligent Powertrain Management [IPM], the fleet has the best chance to improve fuel efficiency. IPM utilizes pre-loaded terrain maps and GPS to look at the upcoming route over a mile ahead and can initiate the actions of acceleration, preselecting gears, eCoasting and braking the engine to maximize fuel efficiency.”

“Fleets should consider both terrain and weather in order to spec the right engine, transmission, and axle ratio,” Slesinski says. “These environmental factors also determine whether a 6×2 or 6×4 configuration will be most effective. Offered as a fuel-efficient alternative to the traditional 6×4 axle configuration, 6×2 drive axles are best for primarily dry-weather conditions over flat, smooth pavement when torque on all four wheel-ends is not critical. For long distances with a full load, a 6×4 configuration can provide the added traction needed in foul weather or on steep grades. With four wheel-ends driving the tractor, a 6×4 tandem axle configuration is preferred on long routes that can span regions with unpredictable weather or steep elevation changes, which describes typical linehaul routes across North America.”

Air disc brakes are also preferred on long or steep grades. With less potential for brake drag, performance and stopping distance are improved over traditional drum brakes.

Duty cycles factor into axle selection. “For diminishing-load applications such as bulk haulers or fuel-distribution vehicles, a fleet may want to spec a smaller axle to save on the initial investment,” Slesinski says. “The lightest weight configuration will also allow for increased load capacity. Alternatively, fleets may select a more robust axle that will support the residual resale value of the truck. If a lighter axle is overloaded, it may result in early repair bills. If over-specified, the fleet may be spending more than necessary and hauling around extra weight. We work closely with vehicle manufacturers to help the end customer examine maximum operating loads, duty cycles, resale values, and all of the potential tradeoffs that go along with these considerations.”

It is important to remember that none of these options should be considered in isolation. Fleets should specify a complete system solution, one that allows the entire powertrain to work together to optimize the performance of a particular vehicle.

Spec right

“The Detroit Technical Sales organization is available to all Freightliner and Western Star dealers, customers and fleets to serve as powertrain spec’ing advisors,” Lehman says. “They are able to assist in spec’ing the right axles and axle ratios for all of their applications, and make sure the fleet has the correct spec for their complete powertrain from Detroit engines to Detroit transmissions to Detroit front and rear axles to correct rear axle ratios.”

“Every day, Dana is working to provide the right axle and driveshaft solutions for a variety of powertrains,” Slesinski says. “It’s our primary focus; we work closely with original equipment manufacturers’ application engineering groups. We also work with many industry peers such as Cummins and Eaton to ensure that our axles perform optimally alongside many different engine and transmission combinations.”