Tracy Bogler describes his company’s philosophy: “The management of Woody Bogler Trucking Co. believes that we should maintain a continuous cycle of improvement,” says the carrier’s president. “Our longevity has given us the experience to understand that change is the only constant in trucking. We understand that we must embrace change in order to provide the service that our customers demand.”

Founded in the 1920s by William Bogler, the current president’s grandfather, the company began using a horse-drawn wagon to carry clay to railroads for transport to brick plants. Today, the fleet hauls dry and bulk freight in the lower 48 states. The Rosebud, Mo.-based carrier operates 142 Kenworth tractors and a mix of Utility 4000 DX dry vans and MAC Trailer Macsimizer half-round, 48-yd. end dump trailers that haul clay, dirt, rock, sand, coal, grain, scrap metal and other commodities.

“We’re replacing all of our tractors,” Bogler relates. “We have a three-year trade cycle based on an average of 120,000 miles annually per tractor, our oldest power units are 2012 models and the newest are 2015. Our goal is to take advantage of warranty coverage as much as possible and to field the most fuel efficient equipment available.”

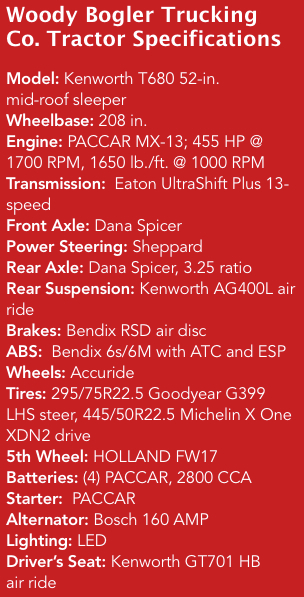

A case in point, the company’s recent decision to standardize on the Kenworth T680 with 76-in. Aerodyne sleepers for long hauls and on T680s with 52-in. mid-roof sleepers for regional hauls, including two of the OEM’s first production units. All of the fleet’s new Kenworths are spec’d with 455-HP PACCAR MX-13 engines and Eaton UltraShift Plus 13-speed transmissions.

Fuel savings

“Initially, we spec’d Kenworth T660 models because of the fuel savings we’re achieving,” Bogler says. “The T660s with PACCAR engines were getting 4/10 of a mile per gallon [MPG] more compared to other trucks in our fleet. After we added 16 T680s, some were getting more than 8 MPG and the fleet average rose to 6.8 MPG.”

“Initially, we spec’d Kenworth T660 models because of the fuel savings we’re achieving,” Bogler says. “The T660s with PACCAR engines were getting 4/10 of a mile per gallon [MPG] more compared to other trucks in our fleet. After we added 16 T680s, some were getting more than 8 MPG and the fleet average rose to 6.8 MPG.”

The fuel economy improvement adds up to about 1.5 MPG overall in the last two years, which equates to $4,000 per year, per truck. Once the entire fleet is converted, including 55 T680s on order for 2014, the math shows a savings of around $500,000 annually.

To maximize fuel savings, the fleet is spec’ing the Kenworth Advantage factory-installed aerodynamic package that includes longer side extenders, lower cab fairing extenders, a front air dam, aerodynamic mud flaps, a rear fairing without steps coupled with an air deflector, exhaust cut-out covers, and wheel covers for drive tires. On T660 models, the fleet is installing the FlowBelow Tractor AeroKit with aerodynamic wheel covers and tandem middle fairings. On new dry van trailers, side skirts from Utility and AT-Dynamics are being added. Additionally, all tractors and trailers in the fleet are fitted with Michelin X One wide base drive and trailer tires. To improve fuel efficiency by maintaining proper inflation pressures, it is using Stemco Bat RF tire pressure monitoring systems on tractors and Meritor Tire Inflation System (MTIS) by P.S.I. automatic tire inflation system on trailers.

Reducing idle time

The fleet is also focused on reducing idling. Espar Airtronic cab air heaters are standard on new tractors and the company is evaluating 20 Idle Smart automatic engine start stop units. “We’ve been testing Idle Smart in cold weather and feel they will provide an even greater advantage in fuel savings in warmer weather when drivers need to keep the cab cool,” Bogler says. “We’ve also had some battery drain issues that we think we can address with the Idle Smart Battery Protect feature that continuously monitors voltage levels and starts and runs the engine to recharge batteries.”

For its new Kenworths on order, the fleet is changing to 6×2 rear axles. “While we wanted to reduce weight, especially in our bulk operations,” Bogler states, “we also saw a fuel savings about 5/10 MPG in testing. Additionally, the 6×2 axle configuration is another way to improve fuel economy without the need to involve drivers. With that system, automated manual transmissions, automatic tire inflation systems and other specs, we’re doing everything we can to improve fuel

efficiency.”

The carrier has worked to continually identify practices to bring customers the level of service they have come to expect. “Our time-honored reputation for reliability, coupled with controlling expenses,” Bogler says, “remains the hallmark of this company’s longevity.“