Air disc vs. drum brakes

So what about the difference between air disc brake chamber sizes and how does the performance of each differ?

So what about the difference between air disc brake chamber sizes and how does the performance of each differ?

“Air disc brakes are typically more effective than drum brakes, and therefore require smaller service chambers than drum brakes for the same application,” says Haldex’s Dunkleberger. “Chamber size and configuration should be checked when servicing air disc brakes.”

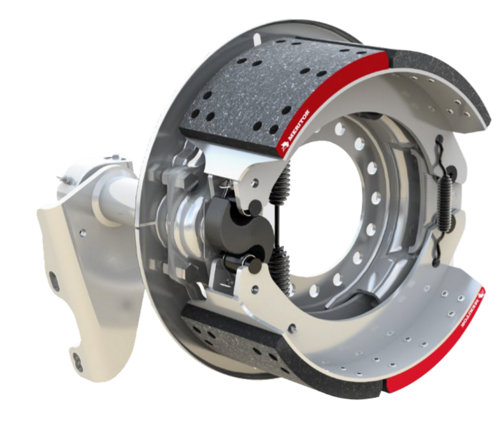

“Air disc brake systems use a brake actuator and wear compensation mechanism,” Stemco’s Geist says, “which is integrated into the caliper and designed based on OEM performance criteria. Drum brake systems utilize an actuator and brake adjuster that is separately serviceable lowering maintenance costs and offers capability for modifying the ‘AL factor’ based on desired braking performance.”

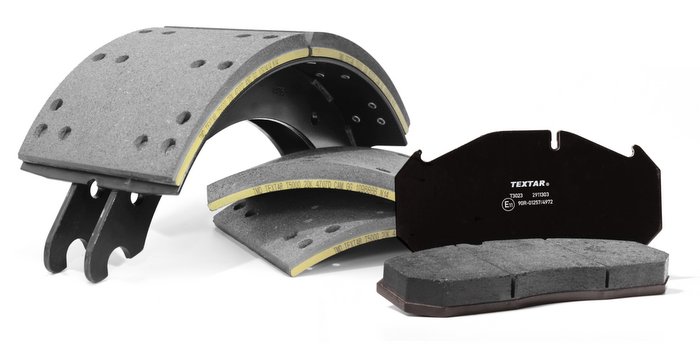

“The friction material utilized in air disc brake pads is engineered specifically to the application to provide the best overall performance for braking and field service life,” says Tony Ryan, SAF-Holland’s technical services and training manager. “The introduction of pads that are not properly specified for that particular application may consist of friction material compositions that could greatly diminish the overall performance characteristics of the ADB system. Air disc pad manufacturers use Jurid539 as a compound for trailer disc brake pads. Performance problems such as accelerated wear, and in some cases cracked rotors, may be encountered when fitting truck disc pads to trailer axle/brake applications. Truck air disc pads are a manufactured with significantly more aggressive compounds to meet RSD legislation.”

“Meritor offers both disc and drum friction materials (pictured left),” says Gopi Krishnan, Meritor’s senior director of brakes for North America. “We determine the customers’ vocation or application need and tailor a specific friction material to their specific vehicle needs.”

“Fleets need to consider that air disc brakes tend to use smaller air chamber sizes compared to drum brakes,” notes Joe Kay, Meritor’s director of engineering and brakes for North America. “Less air consumption results in improved efficiency. The smaller air chambers result in fleets having the option of reducing the number of air tanks used if equipped with air disc brakes. Fleets will have a larger variety of air chamber sizes, which result in multiple air consumption situations. They will also experience the mechanical advantage of air disc brakes over drum brakes in terms of air disc brakes using less mechanical force, resulting in smaller air chamber sizes over drum brakes. Smaller chamber sizes result in less air consumption which in turn results in improved efficiency.”

TMD’s Thompson agrees. “Air disc brake chambers are different than cam brake chambers,” he says. “The mounting studs and push rods are unique and not interchangeable. The standard drum brake air chamber types, 20, 24, 30, etc., tells that there are 20, 24 and 30 sq. in. of diaphragm area inside. This also lets the user know what the expected force output will be. For example, if 100 PSI of air pressure is applied to a type 30 air chamber, the output will be 3,000 lbs. Disc brake air chambers are the same in their ‘type’ designations. There are different sizes beyond the well-known cam brake sizes. When European disc brakes arrived in the U.S., they added sizes of Type 18 and Type 22, to better tailor the input force to the brake to get the output torque desired.“