In preparation for the winter months ahead, air lines should be inspected for damage to avoid failure on the road.

However, component replacement is not only for the winter months; it can apply all year round. Although not always necessary, it’s a good practice to replace air lines, and air line accessories, annually to ensure proper working order.

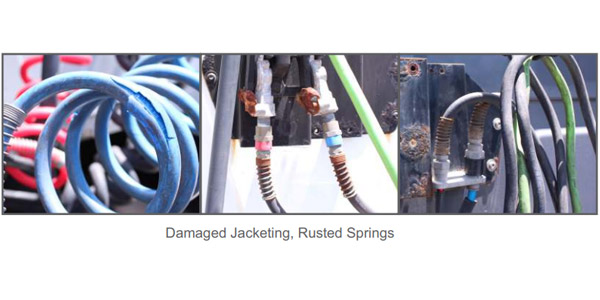

However, during routine PMs, or during pre-trip inspections, if any of the following issues are noted, air lines should be replaced much sooner to avoid possible air line failures, leading to downtime, or CSA violations:

- Chaffing or damaged jacketing;

- Rusted springs and/or fittings;

- Nylon cables that are stretched out and no longer recoil; and

- Kinked nylon cables.

When selecting air lines for a tractor/trailer, most know that it is recommended, and in some cases even required by law, to choose air lines with the following features:

- Air line assemblies that display the appropriate markings which signify compliance with DOT regulations (fequired by law);

- Swivel fittings on the tractor end to avoid corkscrewing during installation;

- Spring guards to protect the hose or tubing from a sharp bend at or near the fitting (fequired by law);

- Added handle grips at the trailer end to provide protection from kinking of air lines during gladhand connection and disconnection;

- Coiled assemblies that extend to their maximum expected service length and return to their retracted position without sag;

- Proper overall working length for the tractor-trailer application; and

- If operating in harsh environments, using cables rated for extreme temperatures (lower than the typical standard of -40°F).

When installing new air lines, its always important to remember the following:

- If cables or handles are color coded, be sure to stall/couple them with their correlating connections (red to red, blue to blue); and

- Always remove the old fitting from the tractor protection valve and install the new fitting attached to the new air lines.

This article was contributed by Phillips Industries.