Allison Transmission has completed the installation of a new e-Axle production assembly line at Allison’s electric axle development and manufacturing facility in Auburn Hills, Mich. This production line integrates automated assembly features and will manufacture Allison’s eGen Power series of fully integrated electric axles, as Allison prepares to progressively increase the output of pilot builds.

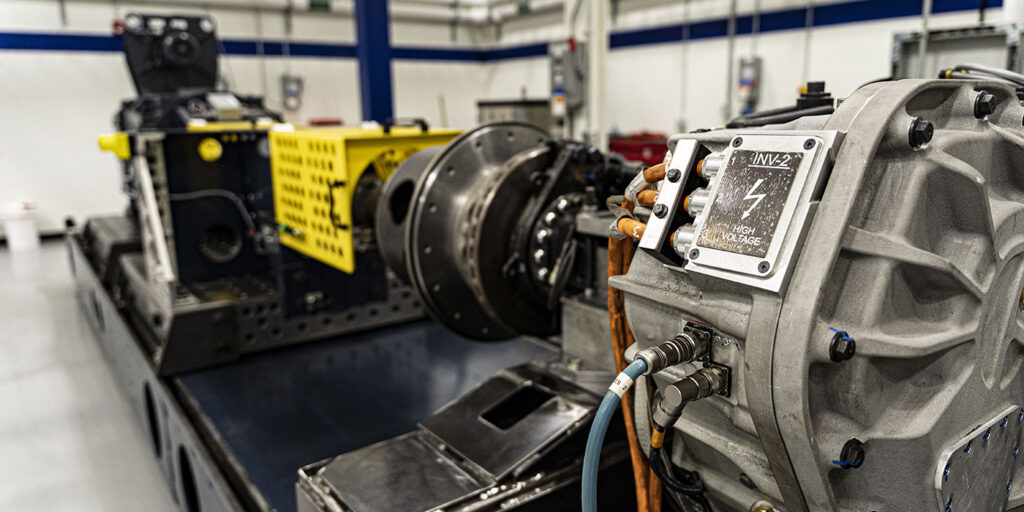

In addition to the production assembly line, Allison has also completed the installation of an e-Axle specific build verification test protocol. Each e-Axle will complete a series of tests to verify every system is functioning to specified performance levels, the manufacturer noted. The test system will ensure that each eGen Power e-Axle is manufactured and tested to Allison’s exacting production standards before it ships. Allison has also made significant investments in e-Axle dynamometer equipment to support fast, repeatable and reliable engineering development and design validation.

The Auburn Hills e-Axle facility is capable of building all products in the eGen Power product portfolio. This includes the eGen Power 100D for heavy duty 6×2 applications, and the eGen Power 130D, which is targeted for European and Asia Pacific applications where a 13-ton gross axle weight rating is required. The facility will also manufacture the 100S, which addresses heavy-duty 6×4 tractors and heavy-duty tandem axle straight trucks, as well as medium-duty truck and school bus applications.