FleetNet: Roadside mechanical repair costs continue to increase

FleetNet America discussed the results of its 2019 Q3 quarterly truck maintenance cost benchmarking program at the Technology & Maintenance Council annual meeting, announcing that the average cost of a mechanical roadside repair exceeded $400 for the first time since the study began in 2017. Additionally, the $407 average cost is 24% higher than mechanical

From tractor-trailer pairing to security: Phillips Connect Technologies details telematics solutions

The new Phillips Connect Technologies (PCT) products introduced during TMC press conference are designed to operate in an open platform, that can interface with non-PCT telematics gateways and with any supplier sensor, or with PCT supplied sensors or a combination of both. PCT’s user interface displays a dashboard of fleet assets, giving the ability to

WABCO introduces a connected, intelligent trailer platform

WABCO Holdings Inc. introduced a connected and intelligent trailer platform. The WABCO intelligent trailer platform is built on four key technologies—an Intelligent Anti-Lock Braking System (iABS); trailer Anti-Lock Braking System (ABS); Intelligent Trailer Program (ITP); and TrailerCAST—as well as open software architecture to facilitate cooperation with key industry players. Introduced in 2019, the WABCO iABS

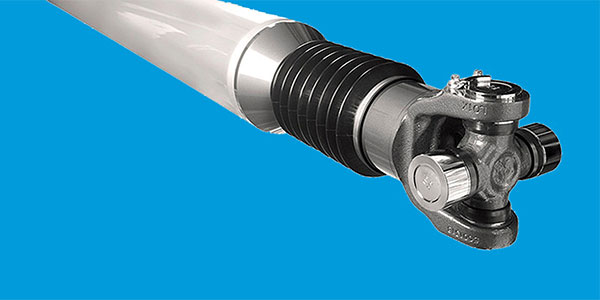

Dana enhances Spicer SPL Series driveshafts to boost efficiency, performance

Dana Inc. announced enhancements to its Spicer SPL Series driveshafts for improved overall efficiency and increased performance. The improvements underscore Dana’s ongoing commitment to its core driveline technologies, providing solutions for evolving customer application requirements. The product enhancements will be available immediately for the Spicer medium-duty SPL series, while updates to the heavy-duty SPL series

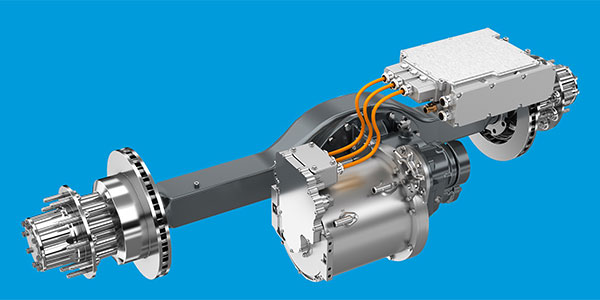

Dana starts production of Spicer Electrified e-axle for commercial trucks

Dana Inc. announced today the start of production of its Spicer Electrified eS9000r e-Axle for Class 4 and 5 commercial fleet applications. The e-Axle will be available for ordering by vehicle manufacturers in the third quarter of 2020. Designed for medium-duty truck and bus applications, the e-S9000r is based on the proven and widely specified

NACFE turns its focus to electric truck in regional haul applications

Through its extensive work on regional haul and electric trucks, the North American Council for Freight Efficiency (NACFE) has determined that regional trucking operations are well suited to be early adopters of electric trucks. It is also a rather large segment of the market with sufficient scale to have a big impact on the industry.

Mitchell 1 updates TruckSeries with interactive wiring diagrams

Mitchell 1 TruckSeries truck repair software was recently updated with interactive wiring diagrams that aim to increase efficiency as technicians can access component repair information directly from inside the wiring diagrams without having to initiate a secondary search. While viewing a wiring diagram, truck repair technicians can click on any component within the diagram to

Matching truck axles to the right vocational jobsite

Application: The Alpha and Omega of equipment spec’ing. Start with the right spec to work as productively as possible with that spec. “Vocational applications place a wide variety of demands on the drivetrain,” said Tony Sablar, vocational marketing manager for Peterbilt. “Consider the differences between a flatbed hauling materials to a construction site and the

Leveraging lift axles in various vocations

Tough truck tasks require tough spec’ing choices. Picking the right lift axle to put to work is often one of the most complicated decisions. Driven by application, lift axles need to meet your expectations and adhere to stringent bridge laws. A quick refresher: The federal bridge formula aims to keep bridges from becoming overloaded, stating

What’s the right axle ratio for vocational trucks?

Carrying your vocational load means balancing the right axle ratio with the right axle weight rating. Just as advanced engine technology and deeper integration have enabled faster axle ratios on-highway, so too have those engine efficiencies translated to the vocational world. “Today’s engines are more advanced and efficient than ever,” said Kelly Gedert, director of

What vocational truck weight class is your axle working in?

Are you a heavy-haul roller or do you cube out before you weigh out? The load that’s riding on your axles shoulders will greatly determine the equipment you spec for your vocational truck application. “Selecting the proper weight rating for steer and drive axles allows the truck to haul the right amount of payload for

Inside the Volvo Trucks electric VNR

Volvo Trucks North America offered a first look at its Class 8 battery-electric project trucks during an event at TEC Equipment dealership in Fontana, Calif. The Volvo VNR Electric project trucks will be put into real-world commercial operations with two of California’s leading freight companies, Dependable Supply Chain Services and NFI. Volvo Trucks engineers and