A 2013 CSA Violation Study by Vigillo, which provides a widely used CSA reporting system that aggregates, organizes and delivers fleet safety information in a suite of CSA Scorecards, reveals that maintenance related issues make up over 80% of all violations among all seven BASICs, or Behavior Analysis Safety Improvement Categories. Furthermore, notes Steve Bryan, chief executive officer of Vigillo, brakes and light make up most of those violations.

That’s hardly news to fleets, relates Gary Ganaway, director of marketing and global customer solutions at Bendix Spicer Foundation Brake. “We asked the members of the Bendix Fleet Council how CSA had changed their business and they said one of their biggest concerns was brakes out of adjustment,” he says. “It is commonly accepted that brakes are a key issue for fleets. While CSA is doing what it was intended to do— focus on safety areas—it is clear that brakes need more attention.

“The Technology and Maintenance Council has done an outstanding job putting together brake related Recommended Practices, which point to the need for a robust PM schedule,” Ganaway continues. “A good system of inspections and PMs and driver practices is extremely important. If the right things are being looked at and technicians are proactive, you can solve problems before they become issues on the road. Some fleets are even installing safety lanes and dedicating maintenance resources so vehicles can be inspected more effectively.”

“While maintenance is only a part of a carrier’s CSA score, it can cause a negative impact on a fleet’s rating,” states John Thompson, sales manager CV NAFTA at TMD Friction. “When maintenance violation data is analyzed, a significant percentage of ‘vehicle out of service’ violations at roadside inspections are for brake adjustment. There are both maintenance and technical solutions that can greatly reduce brake adjustment violations.”

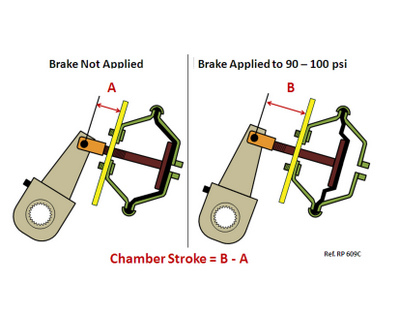

Thompson also points out that education on the requirements of brake stroke is crucial. “There are rules that must be understood, including different stroke limits for standard and long stroke chambers, the 20% rule for out of adjustment brakes, as well as half and full defects for stroke. Daily stroke checks should be performed and any brake out of adjustment should be reviewed and repaired.”

More effective practices

Peter Moss, product manager, brakes North America at Meritor, says that growing awareness as more fleets pay closer attention to CSA violations is leading to more effective inspection and maintenance practices. “Preventive maintenance is paramount,” he states. “Brakes and other safety items need to be checked and maintained on a regular basis. Good pre- and post-trip inspections help make sure the air and brake systems are operating properly.”

Peter Moss, product manager, brakes North America at Meritor, says that growing awareness as more fleets pay closer attention to CSA violations is leading to more effective inspection and maintenance practices. “Preventive maintenance is paramount,” he states. “Brakes and other safety items need to be checked and maintained on a regular basis. Good pre- and post-trip inspections help make sure the air and brake systems are operating properly.”

New technologies can also help address brake related CSA violations, Moss notes. “There are systems becoming available that provide brake stroke information to drivers,” Moss explains. “With continued growth in telematics systems, we are also expecting to see more performance information relayed to service personnel.”

Steve Hampson, director of sales at WABCO North America points to air disc brakes as a technology that can help fleets improve CSA scores. “As brake adjustment is one of the primary issues for fleets that could lead to CSA violations,” he says, “an advantage of air disc brakes is that they are designed with a sealed internal adjuster. That eliminates the need for an external slack adjuster and can virtually eliminate the possibility of out-of-adjustment brake violations.”

According to Phillips Industries, disciplined maintenance and use of the latest technologies can help make out of adjustment brakes a non issue, and that includes the air brake system. If the air system is not properly maintained, the company notes, sludge consisting of oil from the compressor and moisture build up can form and cause valve failure. To eliminate this concern, Phillips advises draining air tanks daily and changing the desiccant filter on the air dryer at the manufacturer’s suggested intervals.

According to Phillips Industries, disciplined maintenance and use of the latest technologies can help make out of adjustment brakes a non issue, and that includes the air brake system. If the air system is not properly maintained, the company notes, sludge consisting of oil from the compressor and moisture build up can form and cause valve failure. To eliminate this concern, Phillips advises draining air tanks daily and changing the desiccant filter on the air dryer at the manufacturer’s suggested intervals.

Gladhand seals should also be checked regularly to make sure they are not dried out or cracked and the use of dust flaps and filters will help keep debris from entering the system through stowed gladhands. Before every trip, Phillips adds, be sure that air lines are properly supported and are not rubbing or dragging on the deck plate, a practice that will also help avoid CSA violations for failing to secure hoses.

Lighting systems

Properly maintaining a vehicle under CSA guidelines, beginning with effective inspection practices, also applies to lighting systems. Mark Blackford, national fleet manager at Grote Industries, says that until recently, fleets may not have been aware of the impact lighting violations have on their operations. “Traditionally,” he relates, “maintenance operations have focused on big ticket items such as brakes and tires, but now that there is a few years of CSA infraction data we can see how lighting affects CSA scores.”

Blackford explains further using data from the CSA website that shows the top 20 violations as of October 2013, including safety lighting (non-headlight) taking up four of the first 13 categories. Specifically, not counting headlights, lighting accounted for 647,125 inspections, resulting in 865,304 violations.

“Note that the number of violations is 1.7 times the number of inspections,” he says. “This indicates that in general an inspection of one possible issue results in seven out of ten times in further violations.

“Lighting problems trigger inspections, which trigger lighting violations, but there is another downside to being pulled over for a tail light problem,” Blackford continues. “Lighting infractions are by far the easiest problems to spot, and once the rig is pulled over, the procedure is to check the entire vehicle. A simple blown bulb can trigger a complete roadside inspection, resulting in keeping the rig on the side of the road for more than just a few hours and the possible assessment of a significant number of CSA points.”

Worthwhile investment

For Blackford, that data makes it obvious that LED lighting should be considered a worthwhile investment. “Replacing incandescent trailer lamps with LED lamps, you can significantly increase your fleet’s productivity and profitability, while also decreasing maintenance downtime and CSA scores,” he says.

“For example,” Blackford continues, “incandescent lamps have a 3.5 year average life expectancy per bulb so a 1,000-trailer fleet can experience more than 1,000 replacement episodes per year, most of which will occur on the road. If that fleet converts all 4,000 of its incandescent stop/tail/turn trailer lamps to LEDs it will incur an additional investment cost of about $36,000, but almost all of those lamps will last the entire life of the trailers, a much lower overall cost when you consider the savings in repairs and the accompanying CSA points for lighting violations.”

“For example,” Blackford continues, “incandescent lamps have a 3.5 year average life expectancy per bulb so a 1,000-trailer fleet can experience more than 1,000 replacement episodes per year, most of which will occur on the road. If that fleet converts all 4,000 of its incandescent stop/tail/turn trailer lamps to LEDs it will incur an additional investment cost of about $36,000, but almost all of those lamps will last the entire life of the trailers, a much lower overall cost when you consider the savings in repairs and the accompanying CSA points for lighting violations.”

Truck-Lite’s Brad Van Riper, senior vice president and chief technology officer, says it is surprising that with all of the positive features of the technology, some segments of the market have not fully adopted LEDs. “Like many electronic technologies, the price has dropped as they mature,” he states. “Durability alone makes LEDs a smart choice, and we’ve seen a significant improvement in CSA scores from adopting LED lighting. There is the potential for lighting violations to drop out of the top items in terms of frequency of repair.”

Mark Assenmacher, director of marketing at Peterson Manufacturing, says that from the viewpoint of over-the-road fleets, the issue is to continue to find ways to better prevent CSA lighting violations for non-functioning lights. “A major cause of non-functioning lights stems from corrosion entering either the trailer’s wire harness system or the connectors on the lamps,” he relates. “One thing fleets can do to fight corrosion and prevent resulting CSA lighting violations is to specify a totally sealed integrated lighting and harness system on new trailers. From a replacement standpoint, fleets should look to upgrade trailer electrical connections to sealed, weatherproof plugs for the lamp-harness interface.”

Mark Assenmacher, director of marketing at Peterson Manufacturing, says that from the viewpoint of over-the-road fleets, the issue is to continue to find ways to better prevent CSA lighting violations for non-functioning lights. “A major cause of non-functioning lights stems from corrosion entering either the trailer’s wire harness system or the connectors on the lamps,” he relates. “One thing fleets can do to fight corrosion and prevent resulting CSA lighting violations is to specify a totally sealed integrated lighting and harness system on new trailers. From a replacement standpoint, fleets should look to upgrade trailer electrical connections to sealed, weatherproof plugs for the lamp-harness interface.”

First step

“CSA violation statistics reinforce the importance of performing vehicle inspections on a regular basis,” says Michael Riemer, vice president, products and channel marketing at Decisiv Inc., “and making sure any obvious vehicle problems are corrected doesn’t give inspectors a reason to perform a full roadside inspection. Fleets should be focused on avoiding CSA violations in the first place and having a proper preventive maintenance program in place is a good first step.

“CSA points out the need for a closed-loop maintenance and repair process that makes sure everything that needs to be repaired does, in fact, get repaired,” Riemer continues. “It shines a light on the importance of having good processes and systems in place to ensure regular inspections, high levels of PM compliance and timely completion of needed repairs.”

Riemer goes on to say that trying to stay on top of maintenance and repairs using a manual system or multiple non-integrated systems is almost certain to result in things slipping through the cracks. “Our Service Relationship Management [SRM] platform captures data in real-time from pre- and post-trip inspections, DVIRs and preventive maintenance inspections so necessary repairs won’t be forgotten,” he relates. “It also keeps track of the not-so-obvious problems so if a truck does get pulled over for a roadside inspection, it passes with flying colors.

“Fleets can control whether they avoid violations in the first place,” Riemer states. “Maintaining vehicles on a scheduled basis and then using data from those inspection reports is a good way to keep inspectors at bay and CSA scores low, especially in the Maintenance BASIC, which makes up the lion’s share of violations.”

For brakes, lighting and any other maintenance related CSA violations, motor carriers can address issues proactively. If proper inspections are performed and all problems are addressed as soon as possible, the risk of being cited for CSA vehicle maintenance violations can be significantly reduced.