More years ago than I might care to admit – 44 years to tell the truth – I became aware of the independent repair shop near my home. As a sophomore in high school, the need for a future career lurked in my subconscious but being a mechanic was not in the embryonic plan. Nevertheless, when you are 15 years old, there exists an acute need for “spending money” to buy important stuff. So, the shop looked like a viable means to make a few bucks.

The journey into shop life started slowly. After hanging around the shop for a couple days after school, I asked the shop owner if he might have something for me to do after school. In fact, he did, namely sweeping up the shop and putting away the tools at day’s end. Consequently, I started learning tool uses and sizes and other mysterious aspects of shop operations.

Once summer break came along he asked if I would like to work full-time to which I answered, sure. Thus, over the summer my shop education flourished to include the complexities of taking things apart and cleaning greasy parts. Thus occupied, I spent my first summer in the shop.

I lived in, and still live in, a small community filled with citrus groves. For those who do not know, orange and lemon trees have some pretty nasty thorns. Those thorns, along with the other junk that ends up on the ground in a grove will wreak havoc with tires, especially rear tractor tires. As a result, one of my first teardown jobs was to remove the orchard fenders from the rear tractor tires, then breaking down the tire to fix flats.

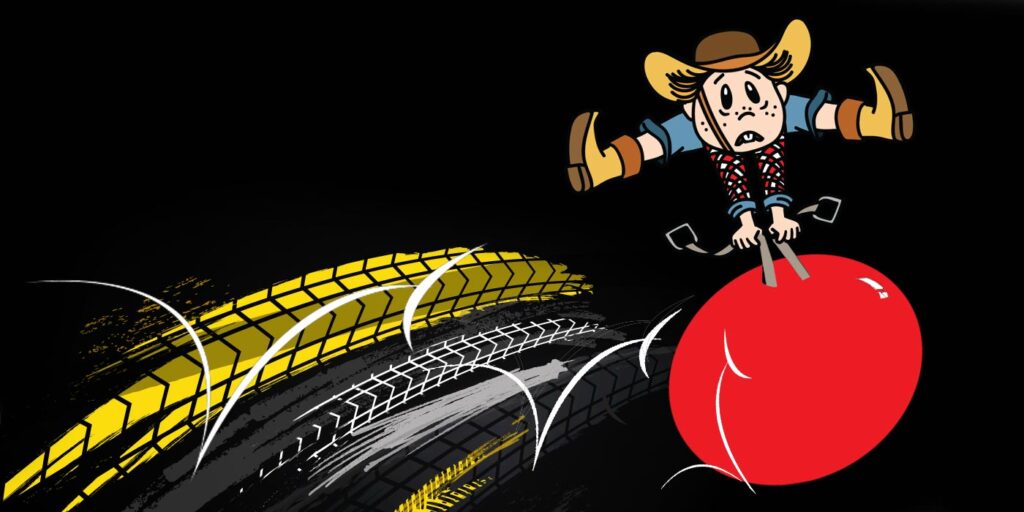

This experience brought about the discovery that the tires were three-quarters filled with water to provide weight for additional traction. This new-found knowledge, likewise, helped to explain why driving a farm tractor down the road is akin to riding a bouncy ball: At higher speeds, the water in the tire stays put and throws the tires out of balance. In a BIG way.

While water is helpful in adding weight for traction in farm tractor tires, it is not a benefit for truck tires. Water may enter a tire by excessive lubricant being applied and not removed during tire installation. Storing tires outside also presents a problem opportunity for rain, snow, bird nests and other assorted junk to end up inside the tire casing.

Foreign material inside the tire can make it difficult to balance and potentially cause a rather bouncy driving experience. More importantly, water and other debris inside a tire can lead to other issues, including potential damage to the tire pressure monitor and tire failure.

A simple step before installing a tire onto the wheel will help eliminate foreign material from inside the tire, specifically inspect and clean out the tire interior. In addition, after soaping the tire during installation, make sure clean any excess liquid from inside the tire. A little uncomplicated effort up front can help prevent bigger problems in the future.

Additional tips for repair and maintenance of Class 4-8 trucks may be found in the Mitchell 1 ShopConnection Truck blog: https://mitchell1.com/shopconnection/category/truck/