Battery electric vehicles (BEVs) have the potential to offer several benefits to operators: lower fuel costs, reduced maintenance costs, and lower total cost of ownership (TCO). However, there are still several barriers that must be overcome before the industry sees full adoption of BEVs and their benefits.

These barriers include:

- Limited range

- Higher upfront cost

- Limited charging infrastructure

- Unknown component reliability

- Increased vehicle weight

- Expected battery life

Out of this list, the most critical are limited charging infrastructure and range. Both of these limitations will be improved within the next 10 years, but until then it will be more difficult for fleets to adopt BEVs.

Limited charging infrastructure

The lack of charging infrastructure can be resolved by state governments, utilities, equipment providers, and customers working together. The vast majority of fleets are planning to install their own charging infrastructure, instead of relying on third-party sites. This means that the responsibility of implementation rests with the transportation company. The largest barrier companies face is cost. This makes available state and federal incentives and rebates critical. The timeline for planning and installing a charging infrastructure is typically two years or more. Fleets should begin discussing their charging equipment needs and layout now.

Limited range

Range anxiety, a term that has been coined within the transportation industry, is the apprehension that comes from not knowing if a vehicle will make it to a charging station before running out of power. The range of BEVs will gradually improve as battery power density improves. In the meantime, range anxiety can be mitigated by fleets using advanced features such as real-time range prediction, advanced route planning, and accessory power consumption estimation.

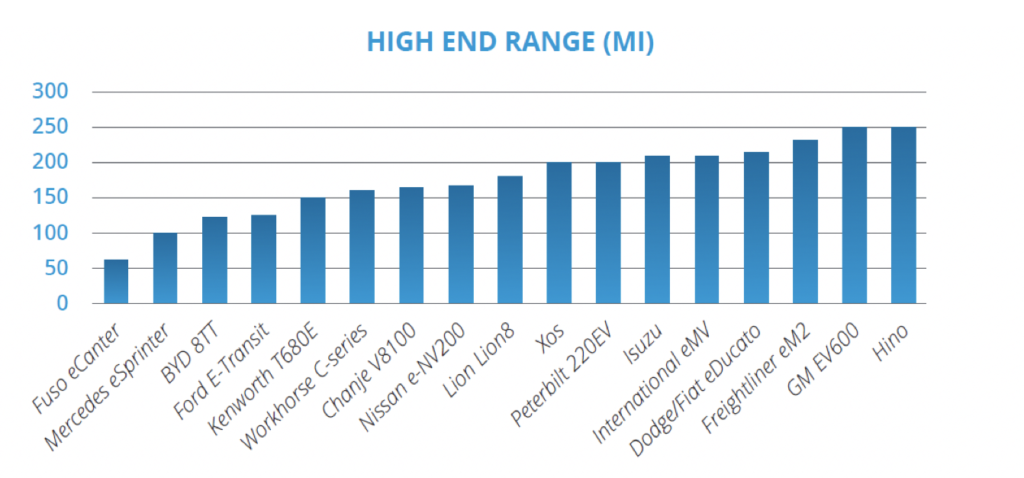

Initially, vehicle range is expected to be between 100 and 250 miles for most light- and medium-duty vehicles, with a higher range typically accompanying higher Gross Vehicle Weight Rating (GVWR). The estimates in the chart below do not consider the decreased range experienced when a TRU pulls power from the chassis, which could impact the range by 30% in some cases. To minimize range loss from TRU operation, drivers should plan to pre-cool their vehicles as much as possible during stationary operation.

One technology that continues to make progress and helps improve a BEV’s range is fuel cell technology.

Progress of fuel cell technology

Fuel cell technology is making progress. In the last two years, it has gained industry acceptance as a viable technology to replace diesel. However, there are a few obstacles that are preventing the industry from clearly seeing the future of this technology. Durability, system cost, fuel availability, and hydrogen fuel prices are the main obstacles that need to be addressed. Fuel cell technology can be a viable replacement for diesel and act as a range extender for BEVs. However, the use of fuel cell technology is not plug and play, and the hydrogen supply chain will create a sharp learning curve for fleets.

RELATED: Hydrogen trucks: How seriously should we take this technology?

Fuel cell technology will likely be best suited for long-haul or regional trucking applications. There are still concerns around how heavy a fuel cell truck could be — potentially 5,000 lbs. more than a diesel truck. Ultimately, economics will drive fuel cell usage in trucking. Fuel availability and pricing will play a heavy hand when it comes time to make decisions about technology investment and fleet adoption, as well as whether or not a hydrogen economy materializes within the next couple of years.

Light- and medium-duty vehicles are in the midst of transitioning to zero-emission technology, and heavy-duty trucks will follow. But full adoption won’t be possible until the obstacles around charging infrastructure and limited range are addressed.

This article was contributed by Paul Kroes, the market insights leader for Thermo King Americas. Learn more about electrification solutions from Thermo King here.