The longevity and comfort of a commercial vehicle depend upon using the best components available for the application. Among the components that contribute to the health and well-being of the driver and passengers, as well as the condition of the vehicle, is the cabin air filter.

When a vehicle is in operation, more than 3,500 cubic feet of air are swept into the cabin every hour. Without adequate filtration, solid and gaseous particles present in the outside air can contaminate the cabin air inside the vehicle. With the potential concentration of pollutants in cabin air being six times that of outside air, the cabin air filter is the only barrier against the exposure of drivers and passengers to these pollutants.

Each season poses different types of pollutants for the cabin air filter to block. In spring, pollen, grass seed, and coarse dirt particles can clog the surface of the pleat bellows. Summer air brings more soot and fine dust. In fall, greater humidity accelerates the accumulation of dust and other particles. Finally, as winter begins, a year of particulate accumulation usually necessitates filter replacement. Otherwise, clogs in the cabin air filter will impede air flow and cabin ventilation, as well as increase the load on the blower. All of these can lead to greater discomfort for drivers and passengers, and cause damage to the heating, ventilation and air conditioning (HVAC) systems that is costly to repair.

One risk to cabin air filters is moisture, which often occurs when a leak causes a clog in the condensate pan or condensate drain line. The culprit is usually a cover that has been improperly seated during installation. The Haynes Manual recommends that when changing filters, be particularly careful about those below the windshield, as incorrect installation may enable moisture to penetrate the filter if the seal is not intact.

Normal conditions can also expose the filter to humidity, especially during warm or wet weather. Studies found that in routine use, vehicle cabin air filters are exposed to humid air more frequently than any other air filters. Sometimes, dust in the filter absorbs this humidity and compromises the filter’s effectiveness. Prolonged exposure to moisture will degrade the quality of the cabin air, as accumulated moisture can cause the growth of bacteria, mold, mildew, and damp odors. Some manufacturers have employed antimicrobial technology that enables their cabin air filters to keep the interior air cleaner and maintain air cleanliness for a longer time.

According to the Haynes Manual, if moisture in the cabin air filter is severe enough, it can leak into the cabin and soak the carpeting. In addition to failing to keep odors and contaminants out of the cabin air, a dysfunctional filter can affect the heater, air conditioner, defroster, and defogger, which can cause condensation to form on the windshield. Accumulated moisture can also make these systems noisy when operated.

- Droplet impact: One of the ways in which water affects the filter is droplet impact. The ability to keep moisture from intruding on cabin air depends upon several factors. According to one study, the pores of the filter media should be less than or equal to droplet diameter to prevent moisture from permeating cabin air.

- Pleat geometry: Another factor that affects moisture in the filter is pleat geometry, which refers to how folds in the paper media are made to increase surface area and enhance cleaning performance. Pleated filter media also minimizes airflow resistance to reduce the load on the blowers. This type of media is available with or without coatings and in various pleat ratios of height to pitch (slope steepness). One study has found that pleat geometry significantly influenced the pressure drop, which is a measurement of resistance to air that passes through the filter. In addition to pressure drop, pleat ratio can also affect cleaning adhesive force and particulate filtration.

- Changing the filter: Even with the best of care, the performance of cabin air filters declines over time and eventually cabin air filters must be replaced. With normal use, they should be replaced once each year or every 9,000 miles; in heavily polluted or dirty driving conditions, every 5,000 miles.

Some types of cloth and carbon media are reusable; they should be cleaned with low-pressure water flow from the clean side to the dirty side. All paper media, however, cannot be cleaned and must be replaced.

According to AAA Automotive, cabin air filters usually are in the ductwork of the HVAC system and are accessible through the engine compartment near the base of the windshield, under the dashboard, or behind the glove compartment. In some cases, the cabin air filter can be changed without tools within 15 minutes, but some filters located in the interior require the removal of fasteners that hold the glove compartment or trim panels in place. The owner’s manual should indicate where the cabin air filter is located. If it is in a spot where access is difficult, many owners choose to have an automotive technician or mechanic replace it. Again, it is imperative to keep moisture out of the cabin air filter when replacing it, especially if it is located underneath the windshield where exposure to moisture is most likely.

Given the importance of keeping cabin air consistently clean, the filter should be changed before 9,000 miles if there is noise, odors, particulates, or weak airflow coming from the HVAC unit. Otherwise, the interior environment could become unpleasant for the driver and passengers, as well as expose them to pathogens and allergens. A dirty cabin air filter also interferes with the proper functioning of the defogger and defroster, which can impede the driver’s vision, and puts excessive wear on the HVAC system.

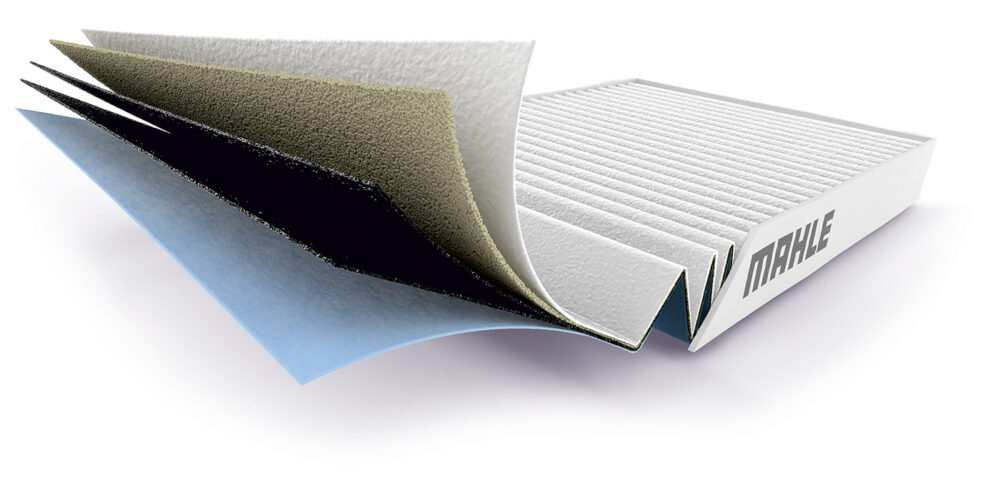

The aftermarket has offered some innovations in cabin air filters that provide consistently clean cabin air to drivers and passengers. Mahle Aftermarket, for example, offers cabin air filters with pleat geometry that optimizes filtration to limit the load on blowers. The assemblage of filter elements in their housings is highly precise to prevent unfiltered bypass air from entering the cabin.

Another innovation that Mahle Aftermarket offers is its line of CareMetix cabin air filters, which features five layers of protection to block odor, pollen, soot, fine particulates, and mold spores:

- A layer with a high-performance particulate filter;

- A layer that functions as a molecular sieve;

- An engineered, activated-carbon layer for adsorption of organic and inorganic gasses to eliminate a range of odors. Adsorption holds pollutants in a thin film on the outside surface or on internal surfaces;

- A bio-functional layer, also with activated carbon; and

- A protective layer that includes an antibacterial coating.

Many people spend a significant portion of their time in cars, especially those who earn their living by driving a vehicle. Innovative and effective cabin air filtration ensures that their health is protected, and their riding experience is comfortable.

This article was contributed by Tom Walsh, head of aftermarket filtration solutions–North America, Mahle.