Wheeler CAT Fleet Manager Scott Cline wanted to reduce the engine idle time racked up by the fleet’s service trucks when technicians were out on jobs.

Idle time was averaging 34% across the truck fleet, with some trucks hitting 50% idle time. The numbers were driving up fuel costs and increasing engine maintenance and downtime.

As a first step, the Wheeler fleet moved to all-in-one solutions on service trucks. But Cline wanted to take that change a step further to maximize potential savings and reduce idle time and costs even more.

A new heating and cooling solution

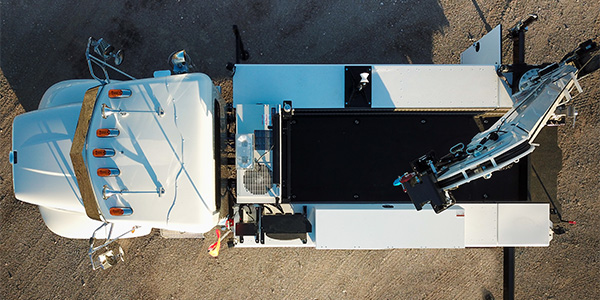

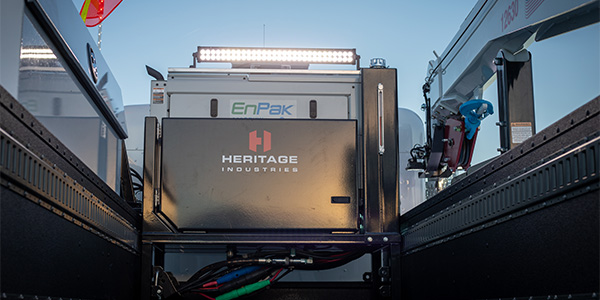

The installation of EnPak® systems several years ago on all mechanic trucks in the Wheeler fleet was step one toward reducing truck idling and decreasing the wear on truck engines. The fleet saw great benefits from the switch.

However, switching to the all-in-one didn’t eliminate the need for techs to continue to run their trucks to heat and cool their cabs for comfort while working on jobsites. The cab climate control was a piece of the puzzle that needed to be solved. Wheeler didn’t want to compromise on tech safety and comfort, so any option had to satisfy the requirement of keeping the cab cool on hot days and warm on cold days.

Wheeler CAT field-tested a fully integrated heating and cooling system for truck cabs that pairs with the EnPak unit. The CabEn™ Climate Pak system for truck cab heating and cooling allowed techs to control cab temperatures without idling the truck engine. The system doesn’t take up truck cab space or require extensive cab modifications, which helps reduce hassle in installation and protect truck resale value.

After several months of testing on a Wheeler truck, data showed that engine idle time dropped by 98% — to an average of just 1% idle time on that truck.

“The reduction was massive, and the idle time on that truck just plummeted,” Cline says.

Idle reduction and fuel savings

In the six-month period before the new system was installed, idle time on the truck averaged 48%, with fuel costs due to idling totaling $700. Cline knew the idle time was linked to weather conditions and temperatures, since data showed that idling peaked on very hot days.

Within a few weeks of the new system being installed — during the heat of summer — average idle time on the truck was down to just 1%, a 98% reduction from its previous level. In addition to the decline in idle time, the truck’s fuel efficiency increased by about 2 miles per gallon with the new system.

“The results we’re seeing are dramatically better than we expected,” Cline says. “It’s a massive difference.”

Best of all, the service tech was happy with the system’s performance and the comfort it provided in the truck cab.

“If it’s 98 degrees outside, is it getting cool enough in the cab? Is it making his life uncomfortable?” Cline says he asked the tech. “He told me, “No, it’s working great.’”

Even on a 110-degree day, the telematics data shows that the tech did not have to idle his truck to cool the cab.

“That tells me this is a huge benefit and he’s not having to worry about it,” Cline says. “He’s just not running his engine.”

Applying those numbers to the entire fleet would result in significant cost savings. Cline says just a 4% reduction in idle time across the truck fleet would save $400,000 to $500,000 a year in fuel, reduced technician downtime, and decreased repair and maintenance (especially related to DPF regeneration and service).

“A new DPF is $3,500 to $4,500, and most of my repairs are regen related,” Cline says. “If you start including the tech downtime and the lost revenue from the truck when we’re down for a regen repair, then our savings from this new system are five or six times what the fuel savings are.”

Ease of installation

Another benefit for Wheeler CAT was the ease of use and installation of the new system. The company didn’t want a climate control solution that would take up a lot of cab space or require modifying the truck significantly. They also wanted a solution that didn’t require a lot of effort on the part of technicians.

The new system uses many existing HVAC components and controls, so the truck doesn’t require major modifications or added components that take up space. And service technicians can turn the system on by simply flipping a switch after they turn their truck engine off.

“The less we have to demand that the tech do, the more it’s going to get used,” Cline says.

Wheeler CAT is happy with the switch and the results. The new system has allowed the fleet to save money on fuel, maintenance and downtime while still keeping technician comfort and safety a priority.

“We’re seeing phenomenal results; so much so that it will probably change how I purchase vehicles and my duration of keeping vehicles,” Cline says.

See how CabEn Climate Solutions can help you slash idle time.