Heavy Duty Aftermarket Dialogue: The future of the heavy-duty aftermarket

The annual Heavy Duty Aftermarket Week (HDAW) is proceeding virtually this year, and as always, it was preceded by Heavy Duty Aftermarket Dialogue, in which executives from OEMs, suppliers and organizations shared their thoughts on the future of heavy-duty service and the aftermarket. Here are some of the biggest takeaways. Panel guests over the course

Heavy Duty Aftermarket Dialogue: How running a fleet changed in 2020

The annual Heavy Duty Aftermarket Week (HDAW) is proceeding virtually this year, and as always, it was preceded by Heavy Duty Aftermarket Dialogue. One particular Dialogue session featured the thoughts of several fleets, who shared their experiences in 2020 on topics ranging from e-commerce and parts ordering to in-house vs. outsourced service to general lessons

Coxreels releases new swivel options for 1125 Series

Coxreels has released two upgraded swivel options for the 1125 Series. The medium pressure (up to 4,000 PSI) and high pressure (up to 5,000 PSI) can both be factory installed on the standard 1125 Series. The medium-pressure swivel is precision machined from solid brass and features upgraded wall thickness, and upgraded seals and backup rings.

Milwaukee Tool releases Packout two- and three-door tool boxes

Milwaukee Tool expands the Packout Modular Storage System with two new drawer solutions: the Packout two-drawer tool box and the Packout three-drawer tool box. Milwaukee says the two- and three-drawer tool boxes are constructed with impact-resistant polymers, all-metal ball bearing slides, and metal reinforced corners. The drawers are designed for easy access to tools and

Five steps to a more accurate truck service diagnosis

In today’s trucks, there seem to be fault codes available for virtually every monitored system. Because these systems interact with each other, it’s not uncommon to see multiple codes being set. In many cases, diagnostic procedures will indicate whether additional fault codes may be set that share circuitry or depend on the actions of another

Tech Tip: How often is lift maintenance needed?

Even the most rugged, low-maintenance lifts need attention from time to time. Give your lift a once-over every day before you use it, check the safety devices, operating controls, lift arms and all moving parts to make sure everything is functioning properly. Look for breakage, excessive wear or other conditions that may affect its performance.

The most overlooked truck tire maintenance practice (and six basic tire service tips)

According to the top truck tire pros that we polled, the most overlooked truck tire maintenance practice is … actually overlooking the tire during the maintenance process. But you don’t have to take my word for it. “A hands-on tire inspection is a commonly overlooked practice,” confirmed Matt Schnedler, product manager for truck and bus

Tech Tip: Be your own cable guy

When was the last time you checked the cables on your shop’s lifts? If you answered “today,” good for you! Cables are one of the things you should check before using your lift every day. In this article, we’ll explore how to maintain your lift cables or “wire ropes,” how to look for damage, and

‘What’s an e-fluid?’ and other electric truck maintenance topics

We’re just beginning to understand the operational and maintenance nuances of electric trucks. They aren’t a one-to-one replacement for diesel-powered trucks. Even topics as innocuous as greases and fluids (yes, fluids are potentially still a part of electric trucks) require new considerations when running electric trucks. Case in point: Shell recently announced its line of

Tech Tip: Troubleshooting your two-post lift

Your lift is critical to the operation and profitability of your business. If it stops working correctly, it’s costing you money. Let’s take a look at how to troubleshoot some common issues and get your lift back to work. Remember to check your owner’s manual for details about your specific lift. Lift won’t raise If

Tech Tip: Ten tips for daily brake lathe maintenance

Like any equipment, your brake lathes need regular care and maintenance to operate at peak efficiency. Keep your brake lathe running smoothly by following these 10 daily tips. Important: Before making any inspection, adjustment or repair, disconnect the power source and lock out all moving parts to prevent injury. Always wear protective clothing and eye

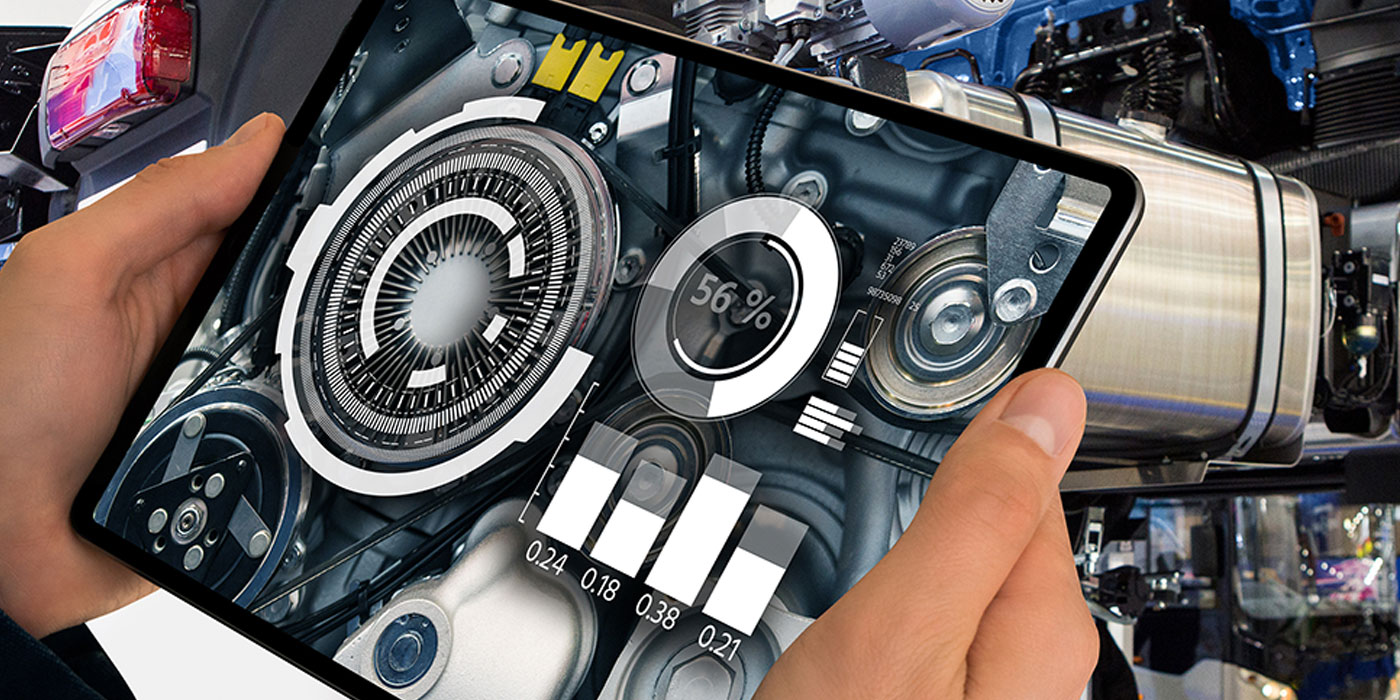

Using technology to stay on top of trailer maintenance

The technology offerings in the trucking industry today are innumerable, so it should come as no surprise that there are several technological methods that can help improve your winter maintenance program. For example, many trailer components can have sensors attached that report data to a main telematics hub, giving you an inside look at the