Proper engine air filtration helps engines perform at their best. When it comes to air filter servicing frequency, Steve Carter, air applications engineering manager for Donaldson notes, “Change your filter when your restriction measurement device tells you to do so. An air filter should be serviced when the restriction indicator shows that the maximum allowable restriction, which has been established by the engine manufacturer, has been reached. Restriction indicators come in the form of mechanical gauges or switches, electrical gauges or switches, or other warning devices. The filter should not be serviced on the basis of visual observation. A filter that looks dirty may actually be operating at peak efficiency. In other words, don’t be fooled by a dirty-looking filter, as this can lead to over-servicing.”

He goes on to say that over-servicing will spur increased service cost in both time and material, and may cause dust contamination of the engine due to:

- Filter damage from excessive handling;

- Increased chance of improper installation of the filter; and

- Increased initial inefficiency.

The efficiency of an air filter increases as it is used. As soon as the air filter is put into operation, it begins to remove harmful dust particles. As these particles accumulate throughout the filter media, many of the microscopic openings in the media become obstructed. This on-going reduction in the size of the openings helps the filter stop smaller dust particles, thus resulting in a more efficient filter. As the filter continues to load with contamination, the filter will develop a dust cake that further increases filter efficiency. The restriction to air flow will increase with this dust loading until it reaches the engine manufacturer’s specified restriction level. This defines the dust capacity of the filter element.

If you’ve ever wondered if air filters should be cleaned by end users or by one of those filter cleaning services, Carter says, “The answer is it’s never a good idea to clean and reuse an air filter. Cleaning an air filter can lead to the same increased service costs and dust contamination issues as over-servicing, while also decreasing the overall efficiency of the filter and potentially damaging it. Cleaning an air filter decreases the dust holding capacity of the filter by 20% to 40% with each cleaning. Attempting to clean a filter with compressed air or a water hose is also a risky business, as the filter media can become damaged. It only takes one small hole or compromised seal to put expensive engines and equipment in jeopardy.

Consult the service manual

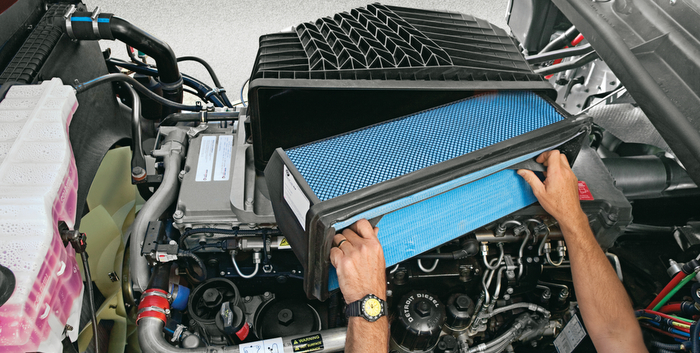

As a general rule of thumb, you should always consult the manual and select the service point according to the service indicator or service switch when considering performing maintenance on the engine air filter. According to Marianne Guldberg, marketing manager at Mann+Hummel Purolator, an air cleaner service becomes necessary when the filter element is exhausted. “Due to possible engine damages and in order to ensure maximum engine protection, the company recommends exchanging rather than cleaning the filter element,” Guldberg says. “If, however, cleaning cannot be avoided, care should be taken that the filter element is not washed out.”

In order to clean the air filter, position a pipe with an end bent by approximately 90° on the end of compressed-air pistol. The pipe must be long enough to reach to the bottom of the filter element. Carefully blow out the filter element with dry compressed air (max. 5 bar) from the inside to the outside, or from the clean air side to the dirty air side until there is no more development of dust. The end of the pipe must not touch the element.

In order to clean the air filter, position a pipe with an end bent by approximately 90° on the end of compressed-air pistol. The pipe must be long enough to reach to the bottom of the filter element. Carefully blow out the filter element with dry compressed air (max. 5 bar) from the inside to the outside, or from the clean air side to the dirty air side until there is no more development of dust. The end of the pipe must not touch the element.

Next, Guldberg recommends that you carefully examine the filter for possible damage. “Never beat or knock the filter element as this will damage it and could be a possible damage to the engine,” Guldberg says. Inside the filter housing there is a secondary filter whose purpose is to prevent dirt from entering the air system when servicing the primary air filter. This secondary element should never be cleaned, but rather be replaced upon standard change intervals. “It is important to take into consideration that a cleaned element will never match the service life and performance of a new element,” Guldberg continues.

After servicing the filter element, carefully wipe out the inside of the housing and the seal contact surface with a moist cloth. Care should be taken so that no dust or dirt gains access to the clean air side of the air cleaner. “When fitting the filter element, make sure that it is correctly positioned in the housing so that the function of the seals is not impaired,” Guldberg says. “An efficient air filter is the basis for optimum fuel combustion. If water enters the air filter housing (as a result of heavy rain, for example), the correct function of simple air filters can no longer be guaranteed, which leads to a decrease in engine power. “You should always look for an air filter with the latest technology in filter media which achieves much higher separation efficiencies. That way you can ensure that you protect the engine at all times,” Guldberg adds.

Best practices

When it comes to the best practices related to engine air filter maintenance, Edward Covington, vice president of quality assurance for WIX Filters, states, “We recommend the following best practices on air filter maintenance:

- Store replacement filters in a clean, dry and safe location. Be careful in handling the filter box to not let it drop onto a hard surface. Filters can be damaged during handling while still in the box.

- Make sure the housing, ducts, clamps and fasteners are in good working order. Leaks downstream of the filters can allow dirt and other contaminates into the clean air stream.

- Make sure the evacuator valve is functioning properly.

- If so equipped, the air filter pressure sensor will alert to when the maximum restriction is reached.

- Remove the filter carefully so that the contaminants stay in the filter.

- Change the inner air or safety filter on the schedule recommended by the vehicle manufacturer.

- Make sure the filter is properly seated and the clamps, bolts or wing nuts are properly tightened. Do not over tighten plastic wing nuts.

- Older style filters with wing nuts generally come with a replacement sealing washer. Use of a worn washer could cause air to bypass the filter.

- Always follow the instructions provided with the filter.”

Extending service intervals

Donaldson’s Carter says, “On-highway fleets interested in extending service intervals should consider using Donaldson Blue air filters with Donaldson’s advanced Ultra-Web nanofiber technology. These filters are guaranteed to last twice as long as conventional cellulose filters, making them the best choice to reduce maintenance costs and increase uptime for on-highway trucks.

Ultra-Web nanofiber technology causes submicron contaminant, like soot, to load on the surface of the media, which promotes lower restriction and longer filter life. In addition, Donaldson Blue air filters protect engines and help them last longer by providing better initial and overall efficiency compared to conventional cellulose media.

Buying aftermarket filters

Fleets are able to purchase any aftermarket air filter designed specifically for their engine and equipment without concern of voiding a warranty offered by an OE. Carter says, “As long as the manufacturer’s recommended maintenance practices are followed, the warranty is protected under the Magnuson-Moss Warranty Act, which deems it illegal for companies to void a warranty or deny coverage under the warranty simply because an aftermarket or recycled part was used. When purchasing aftermarket filters, Covington says, “First and foremost, buy your filter from a trusted supplier and select a reputable filter manufacturer’s product. Another important point is to make sure the filter is listed in the filter application section of the product catalog. After all, some filter applications require self-extinguishing filter media, also known as fire retardant media. From a warranty standpoint, make sure the filter is backed by an appropriate manufacturer’s warranty, and keep in mind that a factory trained filter representative can assist with recommended product selection and inventory levels, change out periods, and proper installation procedures. The bottom line: There’s more than just a filter in a box.”

Purolator’s Guldberg says, “In today’s competing industry, it’s important that you do some research before you purchase aftermarket engine air filters. Some may think that the quality of the air filter is not an issue and that they are more or less all the same. “This is not true,” Guldberg says. “Taking into consideration that the modern engines are becoming more efficient and therefore requiring higher demands on air filters due to the increase in air volume passing through, filters have risen proportionately.”