Say your driver is out on the road and notices something wrong—liquid is leaking from the engine area. The driver suspects a coolant leak, but how can he or she know for sure?

It’s an important question. Coolant leaks are serious business.

“Coolant leaks can be very damaging, as they reduce the coolant level, lower coolant pressure and lead to air entrapment in the system that can lead to engine overheating, lower MPG and increased emissions and corrosion,” says Colin Dilley, vice president of technology for Prestone.

So let’s start with the basics: where to look, and what to look for.

“When a coolant leak is suspected, it is important not to jump to conclusions,” notes Jake Schell, associate product manager for Mitchell 1’s Commercial Vehicle Group. “Take the time to view the appropriate service information for inspection procedures. Coolants are available in different colors, making it difficult to just look at the fluid to identify.”

Schell points out that you can’t limit your inspection to the outside of the engine and radiator.

“Coolant leaks can occur internally allowing coolant into the combustion chambers or lubrication system,” he continues. “Leaks may also show up in the cab through the heater. In some cases, the DEF tank will have coolant lines flowing through the tank. So, it is worthwhile to note particulars for the vehicle in question before jumping in, and again, always check your repair information resource, such as TruckSeries from Mitchell 1, to validate.”

“The most likely places to check for leaks are at hose clamps, then the water pump seal,” says Dan Holdmeyer, industrial and coolants brand manager at Chevron. “It’s important to know which pumps and pump seals fail much more frequently, somewhere around four times as frequently, with conventional coolants versus extended life (OAT) coolants.”

Is it a coolant leak?

There are a few examples of unrelated issues that may be mistaken for a coolant leak.

“New engine design has become very complicated and it is very difficult to determine what product or what type of functional fluid (coolant, brake fluid, power steering and transmission fluids, motor oil and so on) is leaking during vehicle operation and from where leaks originate,” says Prestone’s Dilley.

The leak source most commonly mentioned by the experts with whom FE spoke is a broken radiator cap. This is among the first areas you will want to check.

“Some applications experience evaporation either through coolant hoses or due to a faulty radiator cap. In these cases, water will evaporate out and you may notice the coolant level dropping,” says Lauren Lewis, senior technical support specialist of coolant and chemical technology for Cummins Filtration.

“Another situation,” Prestone’s Dilley mentions, “is a blocked or clogged system, i.e. corrosion in the radiator or build up in an engine block cooling system passage. Build-up or corrosion throughout a system can break free and clog key areas, causing the engine to overheat. This will result in coolant boiling and the cooling system pressure increasing above the designed pressure. The excess pressure will cause steam to vent out of the radiator cap, again causing a loss of fluid in the system.”

When tested with a cooling system radiator pressure kit, Dilley says, a broken radiator cap or a blocked or clogged system will each result in no pressure drop in the system.

How to know if it’s coolant

Luckily, there are a few ways of telling whether it’s coolant that is leaking.

“If the technician suspects a coolant leak, a first step would be to check the results of the engine’s most recent used oil analysis report,” says Darryl Purificati, OEM technical liaison for Petro-Canada Lubricants.

From this report, you’ll want to look at the levels of sodium and potassium, and whether glycol is present in the engine oil.

Let’s start with the former.

“When both sodium and potassium are present in noticeable concentrations, this is a sign that coolant is attacking the aluminum,” Purificati says. “No other mechanical issues manifest in this way, so it’s a clear indicator that there is a coolant leak.”

It’s important to know what kind of coolant the truck uses, as that informs what you should look for. Some coolants have potassium as a component, in which case that’s what you want to look for; for others, you should keep an eye out for sodium.

“For our Shell Rotella ELC coolants, we’d primarily be looking for potassium, and potassium in typical engine oil analysis should not be present at a significant amount,” says Stede Granger, OEM service manager for Shell. “If it’s somebody else’s coolant, they might use sodium instead of potassium.

“There are occasions when you see potassium in engine oil and it’s not coming from a coolant leak. This is typical in a very new truck that’s maybe had one to three oil drains, maybe four at the most, but in that brand new truck that potassium, we believe, is coming from the intake system of the vehicle. But here’s a clue: what we see with that potassium is a certain amount of aluminum.

“So if we would see elevated potassium and no aluminum, then we would suspect a coolant leak. If we would see elevated levels of potassium and elevated levels of aluminum and then we look and see, it is a fairly new truck, this is the first oil drain or second drain, then we would believe that would be potassium that’s coming from the intake system and we would not be concerned. That’s a normal thing; almost every manufacturer of the engines or trucks have that same phenomenon, and it eventually goes away as the truck goes through multiple oil drains.”

According to Granger, you should look for approximately three to four hundred parts per million potassium as your indicator of a significant coolant leak.

Another simple way to check for the presence of coolant, Petro-Canada’s Purificati says, is to use a blotter test. If the oil appears unusually thick, it may have been contaminated by glycol.

“In most cases, you can identify evaporation by checking the glycol concentration,” says Cummins Filtration’s Lewis. “If the glycol concentration is increasing and you’re using a premixed product for top-up, then water is likely evaporating out of the system.”

“System pressure test kits can be helpful in determining if leakage is occurring. A UV dye kit can be useful for detecting external leaks,” Lewis adds. “Internal leaks are more difficult to identify. There are some dye kits available that react in the presence of combustion gas. Combustion gas leaks also contribute to coolant degradation. Glycol degradation can be tested via a coolant lab test.”

Prestone’s Dilley also recommends using the pressure testing kit. “Raise pressure to that indicated on the radiator cap, and then see if the radiator maintains pressure, or even if the required pressure can be reached,” he advises. “This will force coolant out through the leak(s), to allow one to look for the drip and to follow back to the source. To more easily locate a leak, add fluorescent dye to the coolant system, run the engine for a few minutes to mix with the coolant, and then use ultraviolet light. The leak will fluoresce.”

In general, it’s important to keep up with regular coolant maintenance practices.

“The most important thing is to check functional fluid level and condition routinely, and to add fluids as needed in accordance to engine/vehicle manufacturing recommendations or your internal fleet maintenance protocol,” says Mark Alexander, director of product management for Old World Industries. “In any case, if fluid level needs to be corrected by adding the proper type of approved material, the entire system needs to be inspected by tightening coolant, brake and power steering fluid caps, hose clamps, connectors and elbows. In addition, each system needs to be checked for leaks by using appropriate practices recommended for your vehicle.”

Using software to address coolant issues

Service software options, such as diagnostic tools, can also come in handy when a coolant leak is suspected.

“A coolant leak is a great example of how a technician is often required to pair their visual inspection skills with the findings of a diagnostic tool,” says Scott Bolt, Noregon director of product management. “A diagnostic tool can point a technician to a low coolant fault or a fault indicating overheating caused by the leak, but the technician must perform an adequate visual inspection to determine the location of the leak.

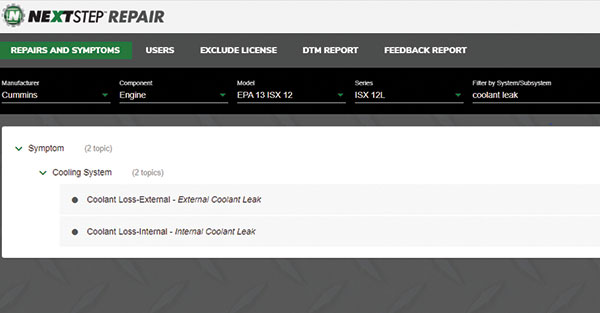

“Fortunately, tools like NextStep Repair help with the repair once that visual inspection is completed,” he continues. “Using NextStep Repair, technicians enter the engine parameters in the searchable database, filter the results to coolant leaks, and have step-by-step directions in front of them for troubleshooting the symptom-based issue and easy-to-follow repair instructions to complete the job once the root cause is determined.”

More coolant info from FE: read “Ten things you need to know about your coolant” here.