Late last summer, just before Cummins unveiled its Class 7 all-electric concept truck, the engine OEM took journalists through a tour of its technical center, an incubator for the hatching the next generation of powertrain technologies.

We walked through corridors of testing bays. The rumbling of super-secret prototype engines being put through rigorous testing procedures growled through large, locked double doors. Wrenches sat next to laptops on mobile work stations—the dichotomy of the tools necessary to craft yet-to-be-seen innovations on display.

We neared two engines perched side by side at the end of the hall: one smaller, in a mostly finished state, sporting the signature Cummins red; the other a beast of a big-bore block tangled in electrical wires.

“No pictures please!” a voice yelled from somewhere behind us.

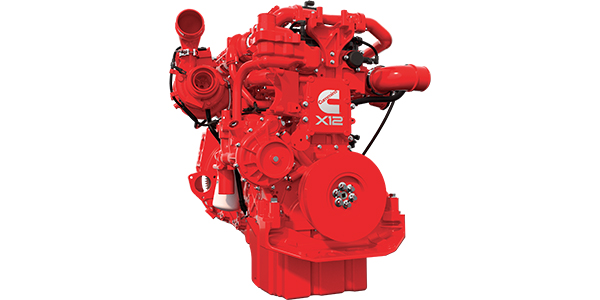

There in the halls of the Cummins Technical Center sat the future—the nearly finished X12 and the next generation of X15. While details on the engines were scarce at the time, the message was clear: Each iteration of Cummins engine—starting with the X15 Efficiency and Performance Series engines launched in 2016 and progressing through this year’s X12 and the still-in-development 2022 next-gen X15—is a building block toward the power of tomorrow.

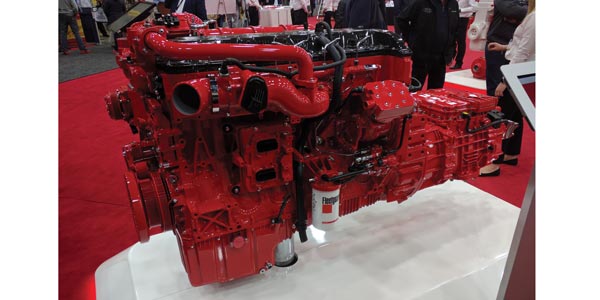

Fast forward to March of this year, and the X12 sat proudly in the Cummins booth at TMC’s Annual Meeting and Technology Exhibition, paired with the first heavy-duty automated transmission to come of the Eaton Cummins Automated Transmission Technologies joint venture, the Endurant, representing a diesel powertrain from the Cummins Integrated Power portfolio. And now it’s ready for prime time.

Let’s get the specs out of the way: In the medium-bore space, an integrated X12 powertrain (the Cummins X12 and the Endurant transmission) sheds hundreds of pounds—approximately 800 lbs. when compared to the X15—meaning more freight hauling capabilities. Alone, the X12, with a sculpted block design, weighs in at just 2,050 lbs. while maintaining rigidity and performance, the OEM stated. The engine sports a peak rating of up to 500 HP and a power-to-weight ratio with 1,700 lbs./ft. When combined with the Cummins Emissions Solutions Single Module aftertreatment, weight savings can add up to 40% more compared to earlier emissions systems.

The X12’s spec compared to the X15 means that the engine is specifically targeting applications for which the X15 might be a bit too much muscle for the job.

“Whether it be line haul, regional haul, vocational, or any other application, we have paid close attention to making sure that the X12 product is fully optimized and, obviously, a bit different from our X15 in terms of line haul capabilities,” said Mike Taylor, Cummins’ global powertrain manager. “We believe the X15 will continue to be very important in the line haul space; we don’t think that there’s any trend moving away from big bore products that are phenomenal when you’re talking coast-to-coast hauling. However, we also see that there’s opportunity in and around urban areas related to regional haul applications. That’s specifically what we’ve targeted for the X12. We don’t see it as cannibalizing our X15 product; we see it as adding a new optimized package that will serve this regional haul space really, really well.”

In today’s powertrain world, you can’t talk about the engine without talking about the transmission. The two components are more tightly integrated than ever. So much so that Cummins made a major investment with its aforementioned Eaton Cummins joint venture. Cummins and Eaton each own 50% of the new joint venture with the aim of designing, assembling, selling and supporting all future medium-and heavy-duty automated transmissions for the commercial vehicle market.

“The concept behind it was that we believe that having a legal agreement where we are bound together helps us be able to openly share intellectual property and all kinds of technical know-how in terms of how you do this deep integration,” Taylor said. “There’s nothing that’s hidden. There’s nothing that one side is holding back from the other. It’s completely transparent, which allows us then to be more closely knitted together.”

Which sounds great, but what does that actually mean in terms of product development and brining solutions to the market?

“When it comes to the nuts and bolts of the situation, what it really means is it allows us to keep the engine in its sweet spot,” Taylor explained. “That is: how it shifts and how it behaves in a vehicle to allow the engine to be in its most efficient position more of the time. Obviously, every drop of fuel that is burned is coming from the engine, and so it’s important to keep it where it wants to be in terms of its most fuel-efficient state. Cummins working closely with the transmission manufacturer enables that.”

Taylor pointed to downspeeding as an example of why a deeper partnership between engine and transmission development is so imperative. Downspeeding, of course, is enabled through faster axle ratios that allow the engine to maintain a lower RPM—thus saving fuel—while still providing the necessary power to the axle.

“As you slow the engine down, you have less frictional losses, and you have the ability to keep it in more of a fuel efficient range, burning less fuel. The engine and transmission working together enable that,” he said. “Having said that, downspeeding can harm performance if you’re not careful. As an engine manufacturer, we need to make sure that the vehicles perform at a high level from gradeability, launch and maneuverability perspectives. This interaction between the engine and the transmission is hyper critical, whether you’re at 2 or at 65 MPH. Being completely transparent between the two systems means that the engine system and the transmission system become one system.”

While fuel efficiency is important, it’s simply a part of getting the job done properly. If your powertrain is perfectly balanced at highway speeds but can’t muster the muscle to haul itself up a grade, then you have problems bigger than fuel efficiency.

Beyond productivity, Cummins is cognizant of truck life cycles and retaining resale value for its customers.

“A second owner may have a bit of a different perspective on what he wants from a truck operation, from total cost of ownership. All of those things play into how we go about developing powertrains,” Taylor said. “Having this joint venture gives us the flexibility not just on the mechanical interface, but also the controls interface to basic features that we develop like adaptive cruise control and progressive gear shifting. All of those things are highly integrated, and being completely open and transparent between the multiple systems makes them possible.”

Power of choice

At a time when electric powertrain development, be it hybrid, hydrogen or all electric, dominate the daily truck industry headlines, it’s a comforting reminder that diesel power is still going to be the driver behind your fleet’s business today and likely tomorrow. And it’s only getting better.

That said, from Taylor’s chair, Cummins is evolving its powertrain technology development approach to be more power agnostic.

“Many of the things we’ve talked about today in regard to diesel automated transmission technology are applicable to natural gas and even all-electric powertrains,” Taylor said. “We just want to be able to offer the right technology. Some customers, who might have applications that fit a pure electric powertrain, will obviously be interested in the pure electric solution, which might not be optimized for other applications. What we want to do is be able to say, ‘Hey, we’re not here to push diesel; we’re not here to push full electric. We’re here to provide whatever the right technology is for you.’

“Our know-how in terms of different applications and the relationships that we have with hundreds if not thousands of OEMs makes Cummins uniquely qualified to be able to offer the right solution with the right technology,” Taylor said. “And we’re really, really excited about where that is taking us.”