Cummins is serious about sustainability. To prove it, they invited me out to their corporate headquarters to talk through the product plan and what Cummins calls “Destination Zero”–a path to zero carbon emissions powertrain options. The big takeaway was that Cummins isn’t going to wait for a single, perfect solution, quite possibly because there is no one zero-emissions powertrain technology to rule them all. There are many options that enable decarbonizing today so that tomorrow will truly be a zero-emissions future.

While I’m still digesting a ton of cool Cummins content, here are some quick takes from the meetings.

Cummins products going forward

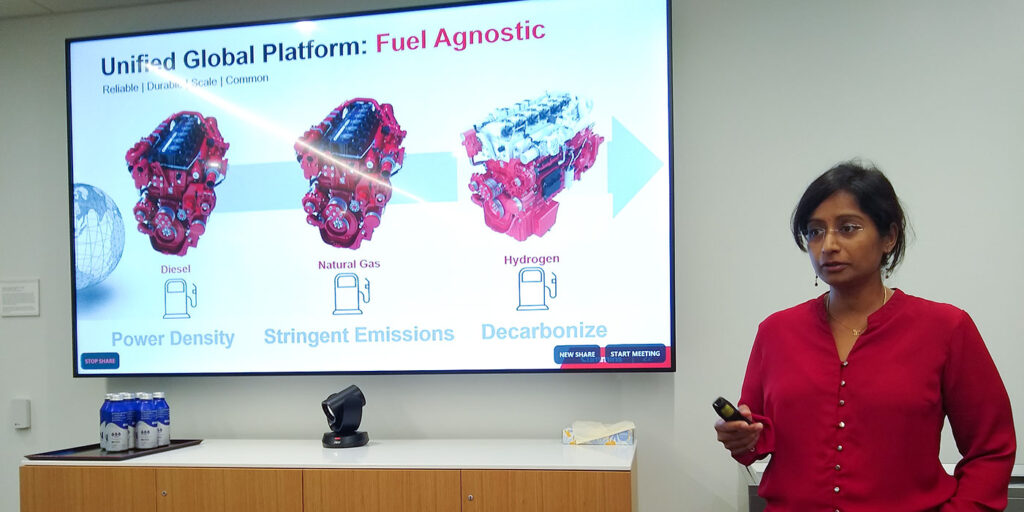

Uma Vajapeyazula, product strategy, Cummins, took to a PowerPoint presentation to give us a rundown of the Cummins product roadmap in the short- and long-term to get to zero carbon emissions transportation. It begins with a mix of technologies that Cummins has mentioned before–cleaner diesel (including renewable diesel), hard-working “diesel-like” gas engines, renewable natural gas battery electric vehicles and hydrogen internal combustion engines (prototype pictured above) and hydrogen fuel cells.

In terms of how electrification segmentation could shake out:

“We believe that, like we have gas on the lighter engine end and diesel on the heavier side, we see the same thing in electrification where battery electric is on the lighter vehicle end where hydrogen fuel cell electric on the heavy-duty vehicle end,” Vajapeyazula said. “We anticipate the messy middle to be a challenge for transportation, the diversity of the portfolio Cummins offers will help the industry transform and navigate [the change].”

Regulations are key to driving emissions down and Cummins is working with regulation entities like the EPA. Here’s what’s ahead, according to Vajapeyazula: Regulatory drivers included 75-90% NOx reduction in the 2020s; GHG EPA Phase 3 in 2030s; and “Destination Zero”–a big driver within Cummins product strategy to achieve zero-emissions scale with electrified technologies and carbon-neutral fuels. Short-term, Cummins aims to reduce in scope three absolute lifetime GHG emissions from newly sold products by 25% by 2030.

On renewable fuels: “Yes, infrastructure is limited, but renewable fuels has a much bigger impact on the environment, and if you bring renewable diesel, you get cleaner trucks on the road today,” Vajapeyazula said.

Natural gas: The next natural step?

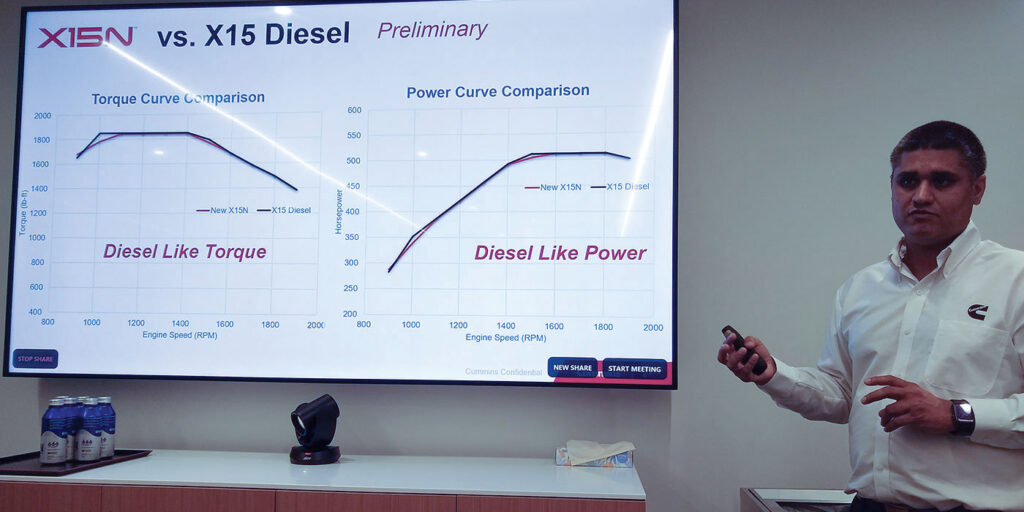

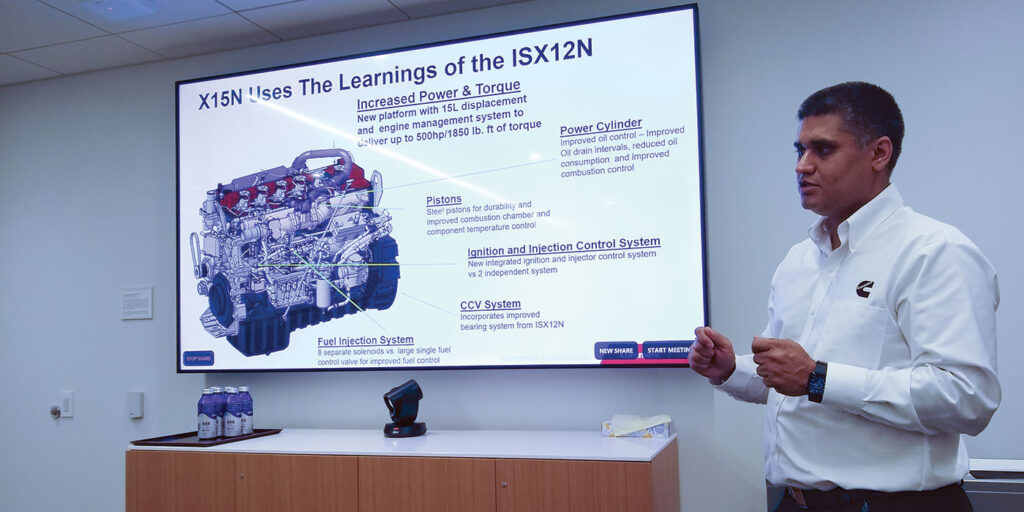

“We think it’s the right time for a 15-liter natural gas engine,” said Puneet Jhawar, general manager, global natural gas, Cummins. “With natural gas, it’s critical that we hit durability and uptime that customers expect. From a drivability standpoint, we’ve pushed it to where it’s as close as it can be as a diesel. It offers up to 500 HP, 1,850 lb-ft with broader peak torque speed bands and it will be integrated with the Endurant Transmission.

The X15N (Cummins nomenclature for 15-liter natural gas engine) is aimed at heavy-duty trucking applications including long-haul and regional delivery.

In terms of natural gas infrastructure, Jhawar noted that Cummins is working with fuel suppliers and fleets to find where the infrastructure is needed most. “It’s a combination of what fleets want and where we’ll see enough density to put in a fueling station. Fueling companies are open to putting stations where truck stops are, but they want to understand how this takes off because they have to bring a pipeline to the location, which is significant.”

The availability of renewable natural gas (RNG) is driving interest from fleets. “Within the market, there is enough RNG to power 30,000 heavy trucks [or 1% of the market],” Jhawar said. “I think there’s enough being put in place to push this technology forward.”

In terms of addressing natural gas engine durability concerns that fleets may have had in the past.

“Everything related to the head and architecture–it’s a clean-sheet design for the X15N,” Jhawar said. “It’s not something we’ve modified. Engineering addressed problems we’ve had in the past and then, to some extent, designed to protect for the future. There’s the element of play [in the product engineering] that we have so we’re not constraining elements at the top level.”

In terms of the decarbonization impact the X15N has, without RNG, moving to the new natural gas engine is an emissions reduction of 16% to 20% compared to a diesel engine. When you add in RNG, you can get to carbon-negative scores, and Cummins noted that can be key when looking at sustainability goals of an entire company, not just the trucks on the road. Jhawar also noted that the new X15N offers an up to 10% fuel efficiency improvement over the previous 12-liter natural gas engine Cummins offered.

Why hydrogen internal combustion engines matter

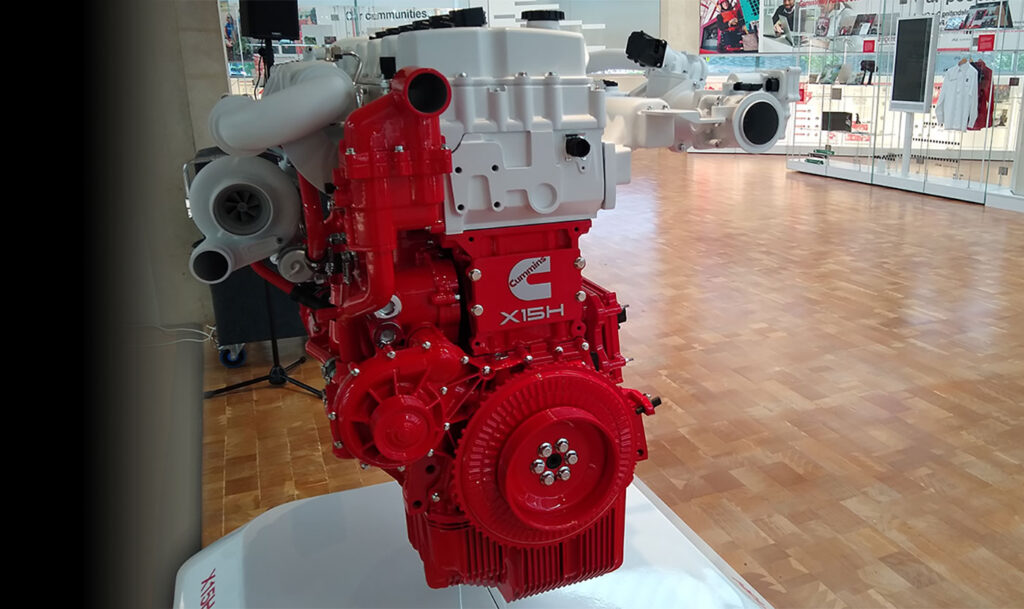

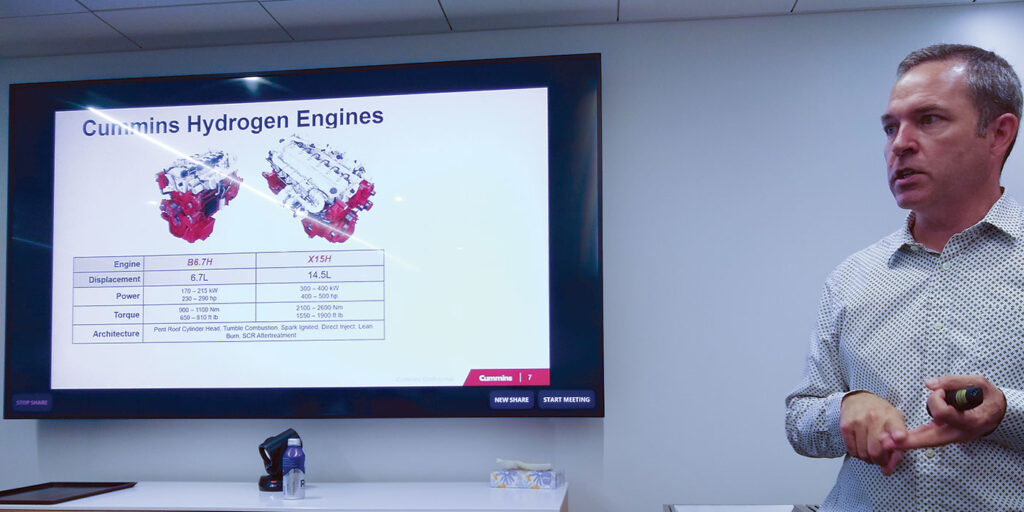

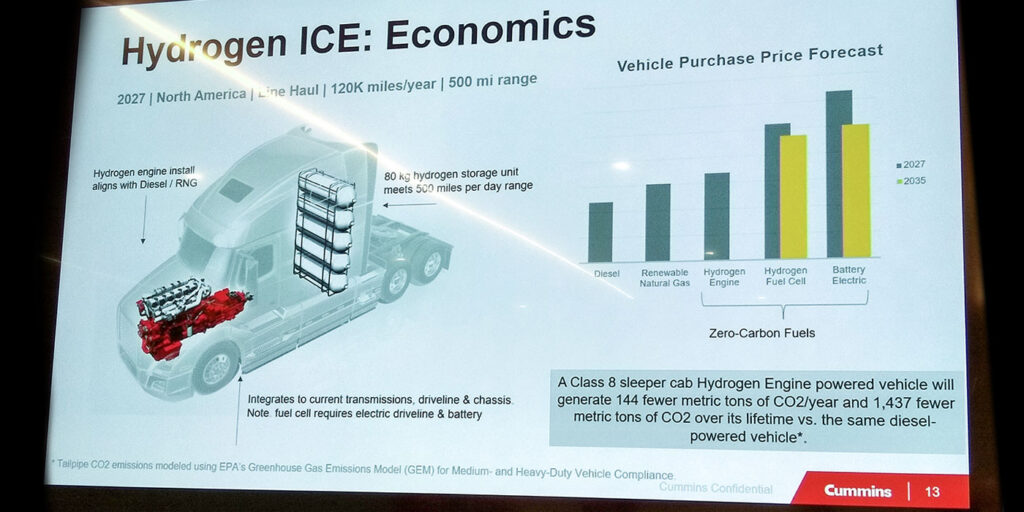

Cummins has announced two hydrogen internal combustion engines (ICE), a 6.7-liter and a 15-liter. Much of the conversation was focused on the 15-liter for heavy-duty trucks, which takes aim at scale production in 2027. The X15H is currently in product development, eyeing pilot programs in 2024.

“Hydrogen is the lowest cost zero-carbon fuel out there and we’re getting positive feedback from fleets that are looking to decarbonize,” said Jim Nebergall, general manager, hydrogen engines, Cummins.

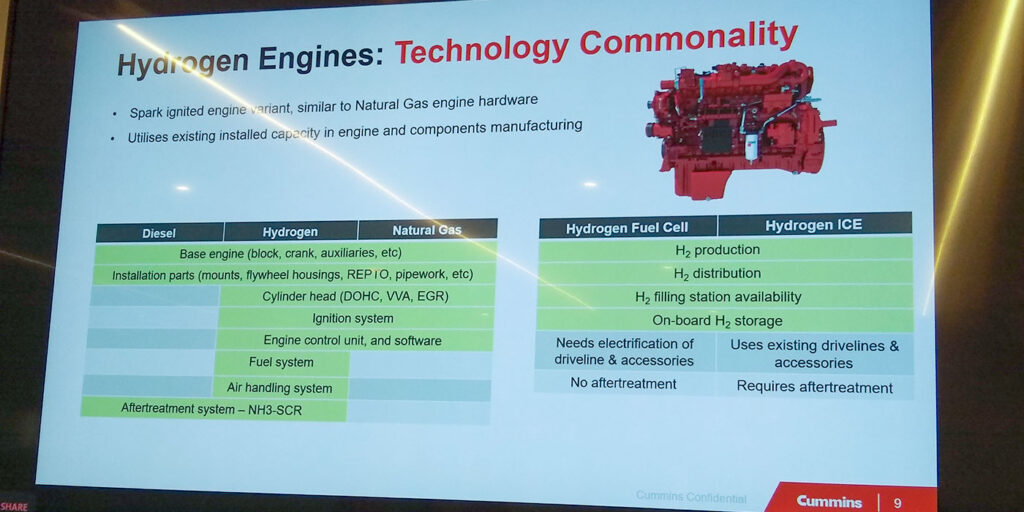

Again, Nebergall reiterated that while there’s a solid place for battery electric vehicles, it’s not a one-size-fits-all solution. A hydrogen ICE presents a level of approachability, Nebergall noted, as it’s still an engine with maintenance that fleets are comfortable with and can relate to, rather than a sea change in truck technology. But it’s a zero-emissions fuel that moves toward decarbonization.

The X15H offers 300 to 400 kW (or 400 to 500 HP) with 2,100 to 2,600 Nm (or 1,550 to 1,900 lb-ft). Nebergall also highlighted the pent roof cylinder head that he said contributes to greater power density along with other features like tumble combustion, spark ignited and direct injection–“lean burn” technology, as Nebergall put it.

Since are no carbon emissions from the X15H, but there is NOx due to being an ICE, it begs the question: is this a transitional technology until hydrogen fuel cells are ready for prime time?

“We don’t know what the future holds,” Nebergall said. “There are a lot of environments we’ve engineered engines to work in. Extreme colds, for example. You don’t have to worry about the engine freezing. I think there’s going to be both [hydrogen ICE and hydrogen fuel cells]. We can move fast with the engine because of our position in the market.”

Where hydrogen fuel cells fit (when they’re ready)

With more than 2,200 fuel cells in operation, Cummins is barreling toward a hydrogen fuel cell pole position as a powertrain supplier with a global fuel cell footprint. (Not to mention May’s announcement that Cummins is partnering with Freightliner on hydrogen fuel cells.)

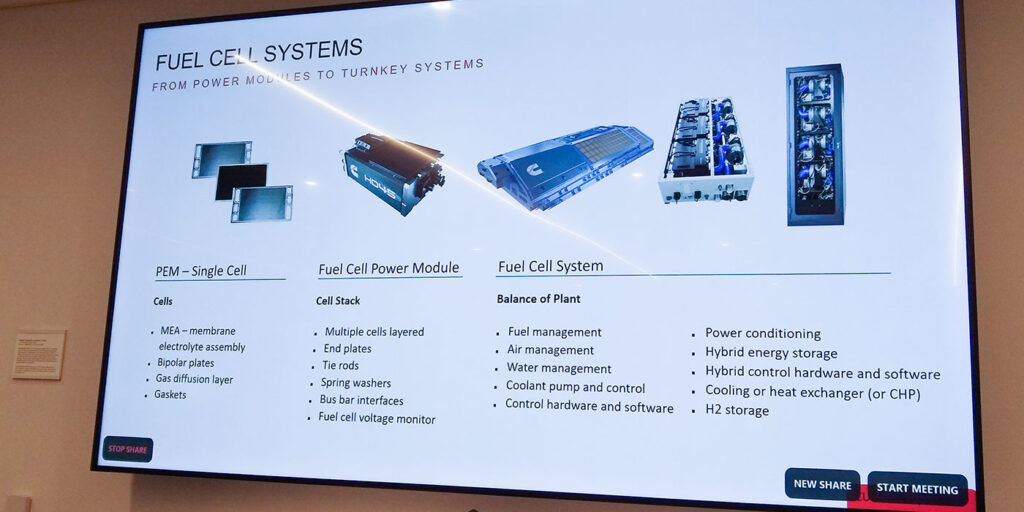

John Carroll, general manager, fuel cell mobility, Cummins, talked about the approach of Cummins building its in-house fuel cell systems, from single-cell “PEM” to fuel cell power modules which incorporate multiple cells layered to fuel cell systems.

The technology can get complicated, so let’s walk through it. Check out the image below. The single cells are the components that make up the fuel cell power module, which is pictured in the center. What goes into a heavy-truck is a fuel cell power module, DC-DC converter and temperature management system.

Fuel cell systems, pictured on the right include, for all intents and purposes in heavy-duty trucks, the electric powertrain. Right now, Cummins is supplying the components noted above. But there’s the pending Meritor acquisition that … well Cummins was tight lipped about that, but you can dream up your own applications.

Carroll did note that announcements like the Freightliner partnership and the 20 PEM fuel cell systems integration into Scania’s battery electric vehicle platform are based on Cummins next-generation fuel cell products, not ones currently in demonstration.

“I personally think hydrogen ICE is a transitional technology, whereas hydrogen fuel cell is the endgame,” Carroll said. In terms of extreme environments or outlier cases where internal combustion engines are reliable, he said, “I made reference to our next generation fuel cell–it won’t be our last generation fuel cell.” His point was that today’s hydrogen fuel cell development might have limitations, such as operating in high altitude environments, but that the systems will continue to evolve and improve.

Making the right powertrain choice

There’s a lot to unpack here. Sitting through the conversations, even I went through the roller coaster ride of feeling optimistic about the reality of powertrain choices that will move toward greater decarbonization to the analysis paralysis that can come with too many options. Talking through the challenge of choice with the Cummins team, it was clear that you have to continually turn the lens back to what’s going to bring the best decarbonization option for the fleet-specific application; not approach it as what fuel will “win” 20 years from now.

The “right” choice is the equipment that gets a fleet’s specific application done, at the desired TCO and produces fewer emissions today than they did yesterday.