Heavy-duty truck filtration is easy to take for granted. Hard-working filters keep engine and cab air clean, allowing both the driver and the diesel powerhouse to breathe deep. While filters become more efficient overtime, they reach a tipping point when they need some truck maintenance TLC.

“If you ignore the diesel engine air filter long enough, it will not end well,” noted Donald Chilton, director, product management, Wix Filters. “Much like our bodies, ignoring maintenance does not lead to a good outcome. An air filter is protecting the engine’s most vital areas. Once it fails to protect you from 99.9% of what it is ingesting, you are guaranteed to replace an engine. Rings, pistons, sleeves, turbos, etc. are all going to be faced with contamination and guaranteed failure.”

It only takes 8 ounces of dirt to destroy the engine of a heavy-duty truck, Wix Filters has noted. This fact makes Wix air filters, which are 99.9% efficient, critical to the life of an engine. When it comes time to replace the air filter, your go-to engine air filter maintenance checklist should include:

• Making sure the housing, ducts, clamps and fasteners are in good working order. Leaks downstream of the filters can allow dirt and other contaminants into the clean air stream.

Make sure the evacuator valve is functioning properly;

• Removing the filter carefully so that the contaminants stay in the filter;

• Changing the inner air or safety filter on the schedule recommended by the vehicle manufacturer;

• Making sure the filter is properly seated and the clamps, bolts or wing nuts are properly tightened. Do not over tighten plastic wing nuts; and

• Always following the instructions provided with the filter.

If you’re wondering if you’re running your air filters too long, Chilton noted that dirt in the air filter housing is a tell-tale sign that you need to tighten up your air filter maintenance schedule. And that’s one of the early signs.

“If it is severe enough and the user ignored the warning signs, the filter could disintegrate,” Chilton warned. “If you think about the volume of air flowing across the filter, it is huge. The engine keeps pumping and draws a huge flow of air. If the filter disintegrates, you will find urethane, metal or adhesive somewhere it is not supposed to be.”

And it’s not just air and detritus that can cause air filter issues.

“We have seen rodents, nests, nuts, baggies and all sorts of junk inside air filter housing,” he said.

When you’re performing maintenance, it’s also important that you replace the air filter with a brand new one. Banging it on the side of the truck or running it under water to clean it can be disastrous.

“Air filter cleaning is 100% always a bad idea,” Chilton stressed. “Even if you don’t intend to damage the filter media, you will. Trying to clean the filter creates tiny holes in the media as particulates are blown or washed away. The holes are not visible to your eye so just don’t do it. Engines are expensive and filters are cheap. The risk vs reward just doesn’t add up.”

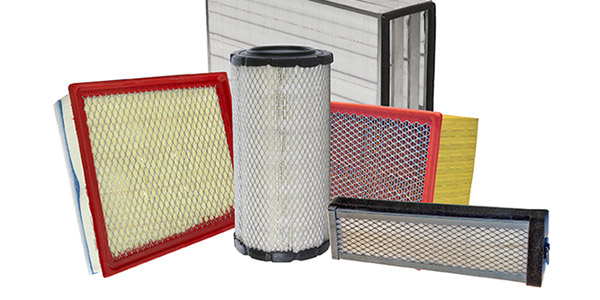

The air filtration media will be a key indicator of filter quality when you’re stocking new filters. Wix air filters, for example, feature embossed pleats and pleat stabilization beads that help the filter trap more dirt and last longer. You also want to make sure your filter of choice has the proper fit inside the air filter housing. Wix premium heavy duty air filters go to the added expense of adding metal end caps with handles, which allows for ease of installation and helps ensure that the filter becomes one with the housing to protect the engine.

For more info on Wix’s line up of heavy-duty diesel engine air filters, visit the Wix website.