It’s already enough of a headache to have to send a truck in for maintenance—pulling a truck from its route for an extended period of time is, of course, not a good recipe for making money with that asset. But if the shop doesn’t have the right part when the truck gets there? That headache gets upgraded to a migraine.

If your fleet runs its own shop, it’s important to stay on top of your inventory levels—tracking how many of each part you have, how frequently they are typically used and when it’s time to order new parts. Many shops now are finding that the easiest way to do this is by investing in parts inventory software, eliminating human error and paper tracking from the equation.

Why is that? Let’s take a look at a few common inventory mistakes that make the case for this software’s value—eight of them, to be exact.

1) Stock management

According to those we interviewed, fleet shops make a wide variety of mistakes when it comes to managing their stock, most of which come down to stocking too many or not enough of certain parts, and not properly keeping track of what parts you have and which ones you don’t.

This is the main advantage of parts inventory solutions: You will always know how much of everything you have.

“Parts inventory tracking is a major money saver,” says Kurt Claussner, president of Fleetsoft. “Reducing inventory carrying cost by as much as 50% can be accomplished. Parts warranty tracking alone can save thousands or, depending on your fleet size, millions of dollars per year.”

According to Richard Clark, business analyst for Chevin Fleet Solutions, many fleet operators are faced with two options when it comes to inventory management: purchased stock, where stock is purchased and sold on with a margin; and imprest stock, where stock is provided and managed by a third-party supplier who monitors stock and keeps it up to date.

“With purchased stock it’s possible to obtain greater discounts, improving margins for sales or reducing maintenance costs; however, there is a financial risk of the part becoming obsolete, damaged or lost,” Clark says. “When it comes to imprest stock, the client carries no financial risk of the inventory becoming obsolete—they can simply return the items free of charge when they are no longer required. On the flip side, if a part goes missing and there is no record of it being used, the client is still liable for the part. It is, in effect, a credit loan that is returnable when no longer needed.”

“Our fleet management software, FleetWave, allows stock categorization and management, meaning that if required, both purchased and imprest routes can be used to maximize the benefits. Being able to seamlessly order, track, manage and report mitigates the financial risk.”

Many parts inventory software solutions include the option for automated inventory replenishment—meaning that parts are automatically ordered when the inventory dips below a certain number. That number can be set by the shop, based on their typical usage of that part.

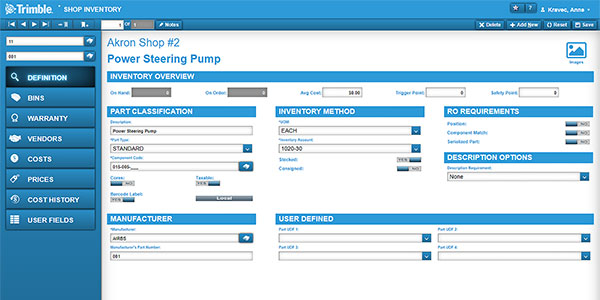

“Automated inventory replenishment saves shops time and is more efficient versus having to call the parts store and place an order,” says Renaldo Adler, industry principal for asset maintenance for Trimble Transportation. “It also helps to eliminate a gigantic inventory of parts that are used frequently, again freeing up space in the shop as well as cash flow. This is available through TMT Fleet Maintenance and TMT Service Center, which integrate with e-commerce providers, and most orders can be delivered on the same day if there are parts stores nearby.”

“A parts inventory management system allows you to specify minimum quantities on hand and warn you when they hit these levels,” Fleetsoft’s Claussner says. “This allows you to keep a low stock level for all your parts, which greatly reduces your inventory carrying costs. Fleetsoft can also automatically determine what your minimum quantity on hand should be based on 90 days of usage. Additionally, with a parts inventory system, you will always know what is on hand and the overall value of the parts in your inventory.”

Additionally, Patrick Fish, inventory specialist with Pluss Software, recommends using priority codes for certain parts. “This creates an ordering routine based on movement but tracked on a deeper level,” he says. “Priority codes of parts can then be ordered differently rather than the same as your weekly stock ordered parts. Also, using rush backorder priority codes will make sure to service the customer in need.”

Jacob Findlay, founder and chief executive officer of Fullbay, says that his company’s software allows tracks how frequently parts are sold and places them in a cycle count group. He says that shops appreciate this feature because it saves them money on inventory shrinkage.

“Shops that regularly perform cycle counts benefit from knowing exactly what is on the shelf, and it also cuts down on inventory losses,” he says. “The system also tracks whether a part needs to be counted based on its cycle count group. This makes it easier for a parts manager to do a little bit of cycle counting every day or every week, versus one huge count at the end of the year.”

So that’s the major issue, but there are quite a few smaller mistakes made in shops that can be alleviated through the right software and processes. Let’s run through a few of them:

2) Unnecessary costs from warranty issues

When starting a repair, it’s important to know whether a given part is in warranty—improper billing of in-warranty or out-of-warranty parts can lead to major headaches and unnecessary costs, both for the shop and the fleet.

Technicians don’t always have access to all the information about when parts were last replaced or whether they are still in warranty, which can lead to these errors. A good parts inventory system can make sure that everyone knows the warranty status of the parts being used from the start.

“Fleetsoft’s parts inventory system can automatically warn you if a part is under warranty by tracking its date added to the vehicle, vendor and odometer placed on the asset,” Fleetsoft’s Claussner says.

“FleetWave enables warranty parameters to be captured. This means that when parts are issued to a job—and the vehicle in question has previously had the component replaced within the warranty period—the user is notified that a warranty claim is due,” Chevin’s Clark says. “In addition to this, when used with Chevin’s Workshop Hub, technicians have access to the maintenance history of the vehicle, including any parts replaced, pre-empting them that a warranty claim is due and reducing the risk for the part being disposed of unnecessarily.”

3) Keeping inventory on shelves for vehicles that are no longer in service

“When we implement TMT Fleet Maintenance (designed for fleets that maintain their own equipment) or TMT Service Center (designed for shops that maintain others’ equipment), we do an inventory review and clear out parts that are no longer needed,” Trimble’s Adler says. “Many repair shops sell the parts they no longer need, leading to significant cost savings.”

4) Properly managing inventory levels for high-usage parts

“Another common issue,” Adler notes, “is managing inventory levels for high-usage parts like filters and brakes and ensuring that there are enough on hand to reduce downtime.”

He also recommends eliminating the storage of expensive parts that are rarely or never used.

“Again,” he adds, “TMT Fleet Maintenance and TMT Service Center provide insight on both sides of the spectrum to ensure a balance of keeping the high-volume parts in stock and eliminating the expensive parts that are rarely used. Our systems also help with managing recalls, all of which helps to reduce downtime.”

Fullbay’s Findlay says that his company’s system tracks part cross-references; that is, if the exact part isn’t able to be re-ordered, the system suggests alternative/cross-reference parts that will be a suitable replacement.

5) Lack of bin locations for parts

Pluss Software’s Fish says this is one of the most common concerns his company runs into.

“A basic labeling system and setup will allow you to count your entire inventory three to five times a year without the dreaded end-of-year inventory count, also allowing you to keep up on cleaning the parts shelves while counting,” he says. “This practice allows you to self-audit at the end of the year by counting a specific amount of your highest moving items.”

Fullbay’s Findlay says that parts tracking is also an important feature. “Parts can be in one or many locations—a part could be in a warehouse and also on ten service trucks. In our system, each location has a min and max for reordering purposes,” he says.

6) Excessive administration errors

“In order to reduce administration errors when it comes to booking parts out, shops should use barcoding used in conjunction with parts labeling at their pick location,” Chevin’s Clark says. “FleetWave and the Workshop Hub can be used to produce and read bar codes to facilitate this enhancement. A recent development in the Workshop Hub now means that device cameras can also read barcodes, removing the need to purchase additional hardware.”

7) Using bar codes properly

“Implementing barcoding will be critical for the success of large shops and parts houses,” Pluss’s Fish says. “Barcoding ensures immediate data entry, so parts are never miscounted while cycle counting manually. Making sure you are completing your purchase orders and stocking your shelves will be a higher priority as well with a larger shop.”

Fullbay’s Findlay says this feature allows users to print and scan barcodes, which allow for quickly adding parts to repair orders on the shop side, and also for a true point-of-sale experience when selling parts over the counter.

Fleetsoft’s Claussner says that in his company’s system, shops can bar code their parts so it is easy to charge them out to an asset, saving time and making the process more efficient and accurate. They can also specify a category for each part to easily create a report or chart showing the total value of each part category is on their shelves and also what amount has been charged out to assets.

8) Allowing proper lead time

“Once you have set up an inventory with proper minimums maximums and priority codes, ordering becomes very simple,” Fish says. “Determine lead-time days for specific vendors and space out your receiving, not your ordering. This makes the time from shipping dock to shelf much more consistent. This not only reduces the stress on the warehouse department but relieves stress on the counter staff who are expecting to have parts to move to the customer.”