By 2040, zero-emission bus sales are forecast to reach 83% of the global market, as the commercial vehicle industry strives to meet zero-emission targets and the cost and asset benefits of EVs compared to internal combustion engines (ICEs) become apparent; and trucks, from light- to heavy-duty, are sure to follow.

Make no mistake: Completing the switch to electric is a major but essential operational shift. While much attention is given to EVs themselves, less is said about the electrical and mechanical infrastructure required to provide optimized power distribution, energy management and in-depot charging capabilities.

Charging infrastructure is the backbone of any electric fleet and must meet the associated power requirements of the vehicles to be charged. The success of any new build or retrofit EV charging project relies on three key sets of considerations: infrastructure, electrical and mechanical.

Infrastructure considerations

In the early stages of project development, examining the existing site conditions is critical. The electrical infrastructure required to charge an electrified fleet will require additional space and provisions, so further investigation and analysis must be given when converting an existing ICE facility to an EV site.

It is in these early stages that a design team should start to work alongside the utility provider to determine the quantity and quality of available power, considering the addition of renewables for on-site generation plus energy storage and backup.

Vehicle range is important too. Understanding the distance traveled by an electrified fleet will determine whether on-route charging will also be required in addition to charging at the main depot overnight. It is essential criteria like this that will determine the level of upfront investment required to transition to electric.

Electrical considerations

Switching to an EV fleet is an essential and positive step, but the new infrastructure must be scalable to accommodate fleet growth. The grid has limitations and adding more vehicles will require a thorough understanding of efficient charging processes, mitigation of peak loads and overall control of the site’s power system.

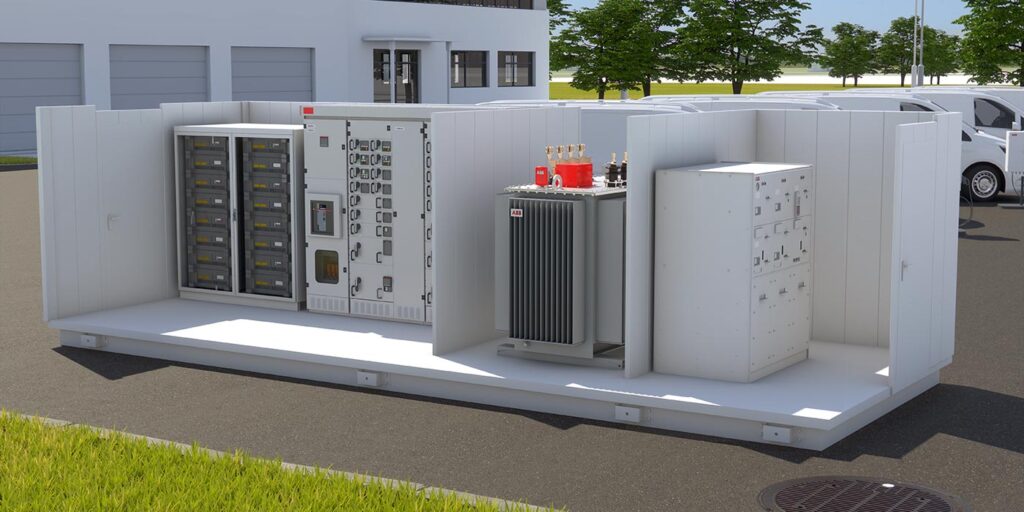

In some cases, the electrical grid will need to supply well over 10 times the power required for a combustion engine depot. This increased power demand often requires the site’s electricity supply to be upgraded to a medium-voltage service of 1,000 to 42,000 volts. For safety, it is crucial that the higher voltage electrical switchgear and components be located within the main building or within a tested and validated electrical enclosure or e-house.

For smaller depots, the use of a battery energy storage system (BESS) can prevent the need for an upgrade to a medium-voltage service by “topping up” the power from a standard low-voltage supply when the vehicles are being charged. Likewise, for bus depots, one option may be to add solar generation with load optimization in conjunction with the BESS. This architecture will help to minimize the utility infrastructure requirements and provide a good first step towards fleet electrification.

No matter how the electrical considerations are configured, a digital management system will be required to coordinate the electrical grid, infrastructure, chargers and vehicles so that they all work efficiently together.

Mechanical considerations

The primary mechanical consideration should be cable management and providing a path between the charger and the vehicle inlet. There is a choice to be made between manually operated high-power chargers, which are those chargers plugged in by hand, or automatic bus and transit charging systems in which the charging interface raises automatically from the roof of the vehicle to connect to the charger.

How to implement the right processes

A solution architecture approach to the deployment of depot charging infrastructures provides value as a pre-engineered optimized solution. It reduces site work and ensures smooth startup, regardless of fleet size or the complexity of the site to be developed.

Solution architectures can combine a range of optimized network components, deliver faster drawings, manufacturing cycles and streamlined start-up and commissioning processes, to encourage rapid deployment of charging infrastructure.

Implementing solution architectures can often be achieved on a modular and scalable basis. This allows for simplified upgrades or additions as the fleet operation grows and increases its power and electrification infrastructure needs.

This article was contributed by Marty Trivette, global solution architect manager at ABB Electrification Distribution Solutions.