The headline asks an important question that may feel too early in the zero-emissions vehicle adoption cycle to ask. As first-adopting fleets do their parts to field electric trucks, install charging infrastructure and start working through the electric truck operation wrinkles, the fact is that sustainability is larger than just OEMs manufacturing electric trucks and fleets buying them. Even if your fleet sports zero emissions at the tailpipes, if the utility providing your energy is fossil fuel-based, then all you’ve essentially done is shift your emissions loads from your trucks to the utility.

To truly tackle the climate change crisis, the cycle of energy has to be sustainable.

“We’re not just thinking about the chargers and the infrastructure to make those work in terms of underground electrical interconnection. We’re thinking about where they draw their electrons,” said Nicole Geneau, senior vice president of development at AlphaStruxure, an “energy as a service” provider.

What is energy as a service? The phrase caught my attention as well. The trucking industry is well aware of software as a service (SaaS—think telematics services), and energy as a service is similar, but instead of data-driven software solutions, it’s the electrons with which you’re charging your trucks.

But it’s about more than just providing energy. An energy as a service provider finances, develops, owns and operates EV charging infrastructure for the customer, eliminating the upfront cost and risk for fleet owners and operators looking to electrify. As part of the agreement, the customer is guaranteed outcomes for energy reliability, sustainability and energy cost predictability.

“The electric truck energy system, holistically, often requires the fleet owner to think about the fuel going into their vehicles, electric or otherwise, as an integrated system within their operations,” Geneau said. “When we talk to them about how they operated their fleets in the past, they didn’t have to think a lot about where the fuel was coming from for a diesel or gas fleet.”

Fleet managers have always been, in a sense, fuel managers (at least in part) by spec’ing most efficient equipment to help save on hefty fuel costs. In the battery electric future, savings comes down to managing charging cycles and ensuring your energy is sustainable and cost effective. That’s what energy-as-a-service company likes AlphaStruxure manages.

“We try to default to on-site power solutions—a combination of solar and battery energy storage,” Geneau began. “Most solar is produced in the middle of the day but most charging activities for fleets take place at night, so you need to be able to use those solar electrons in the evening to charge. Having an on-site solution means you can make that supply of electricity resilient, such that it’s available to you even if there’s no power from the utility.”

That’s right: energy independence, to a degree. Geneau noted that as a fleet moving toward electrification, your fuel source is controlled by the utility. Climate change continues to produce extreme weather, placing greater demand on electric grids that your trucks will come to depend upon. What happens if there’s a blackout? Or rolling brownouts like we’ve seen in California?

Downtime due to unexpected maintenance is one thing; downtime because you can’t charge your trucks is another. So Geneau is going to walk us through on-site energy generation and storage options that aim to move fleets toward renewable energy usage models and ensure you always have the power to be productive.

The two main sources of on-site energy generation

The first is a generator and the second is solar. Let’s detail the first: Ideally, if you’re going to invest in a generator, you’d want it to work off renewable energy. While diesel generators can be a stepping stone toward renewable energy generators down the line, natural gas generators are also available. (Of course you’d want to be sure you’re sourcing renewable natural gas.) And soon, hydrogen fuel cell generators can be put to work for sustainable backup energy generation.

The second, and perhaps more interesting component, is the installation of solar panels at your locations.

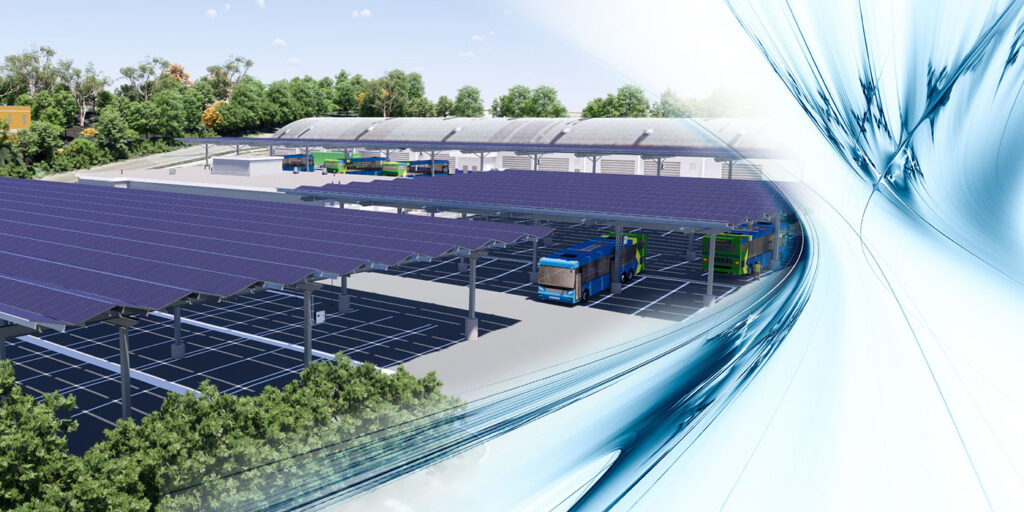

“Solar really depends on the site where your vehicles are parked and how much you can incorporate in that facility—whether it’s on the facility roof or you build a parking canopy to cover the vehicles and generate the solar, which is what we’ve done with a bus depot in Montgomery County,” Geneau said. “We covered the parking lot with solar canopies, which have a couple of benefits beyond making electricity. You’re also now protecting your vehicles from the elements and in some geographies, that becomes hugely important.”

The biggest takeaway is that on-site energy generation isn’t one solution—it’s a combination of energy sources.

“We approach the challenge with a mix of energy sources—it’s a microgrid,” she said. “With charging for most of the fleet operators, charging activity typically happens in the evening and nighttime hours when the vehicle’s not being used for revenue. Solar is produced in the middle of the day so for vehicle charging purposes you need to pair solar with some kind of storage in order to shift the timing when you can use those solar electrons.”

That brings us to on-site energy storage.

Clearly, generator energy storage is pretty straightforward. You have a natural gas source or hydrogen fuel source probably in the form of a tank. You fuel your generator, start it up and produce energy you can use immediately.

Solar energy storage isn’t as cut and dry.

Solar energy generation necessitates on-site battery storage. You’re harvesting the sun’s rays during the day when your trucks are out and about and then storing it for later usage.

It’s a lot, and service providers understand the frustration.

For AlphaStruxure’s part, Geneau recognized that there isn’t a plug-and-play solution. Each on-site energy build is different because each fleet has different operating conditions and energy demands that need to be met. The key is to start talking about your fleet’s challenges.

“Think about parking canopy solar versus rooftop solar versus ground mount solar; the three different kinds of photovoltaic solar panels that have different efficiencies and use different amounts of spaces to produce the same number of electrons. It just gets so complicated,” she said. “When I talk to fleet owners, that is one of the frustrations: this isn’t simple. This isn’t put in a gas pump, and it isn’t just about the vehicle.”

She explained that the solar solutions in AlphaStruxure’s electric bus depot project for Montgomery County will also generate energy to power its facility, in addition to bus charging.

“When you start thinking about producing your own electricity on site, why wouldn’t you also take power to your buildings?” she asked rhetorically. “As soon as that light bulb goes off, then we go to a different part of the conversation, which has two aspects. One, you need a broader number of stakeholders at the customer to be engaged, because it’s about more than just the fleet manager. And two, you start to really dig into the decarbonization of the whole operation, as opposed to this isn’t just about vehicles anymore.”