Every jobsite, application or body demands something a little different from vocational vehicles, notes Len Copeland, product marketing manager at Detroit Products. “There can be power and frame space needs, demands for light weight and a shorter wheelbase for maneuverability,” he adds, “and environmental considerations in extended idle applications or at remote worksites.”

“The first rule is to understand what you like and don’t like about your current equipment,” says Kristopher Ptasznik, powertrain TCO and consultancy leader at Cummins Inc. “From a powertrain standpoint, that includes the engine’s horsepower and torque ratings, transmission type, rear axle ratio, etc. The next step is to look at your performance requirements, including key operational aspects such as the type of surfaces the vehicle will operate on, payload and weight requirements, and desired cab or vehicle size.

“These considerations may influence engine and transmission choices and will dictate minimum acceptable performance characteristics such as low speed maneuverability, startability and gradeability,” Ptasznik continues. “Vocational specific ratings provide broader horsepower curves to help fleets complete tasks as efficiently as possible. A fleet can also choose to leverage fuel economy focused features when the vehicle is traveling between locations as it will not have an impact on the vehicle during the vocational aspect of the duty cycle.”

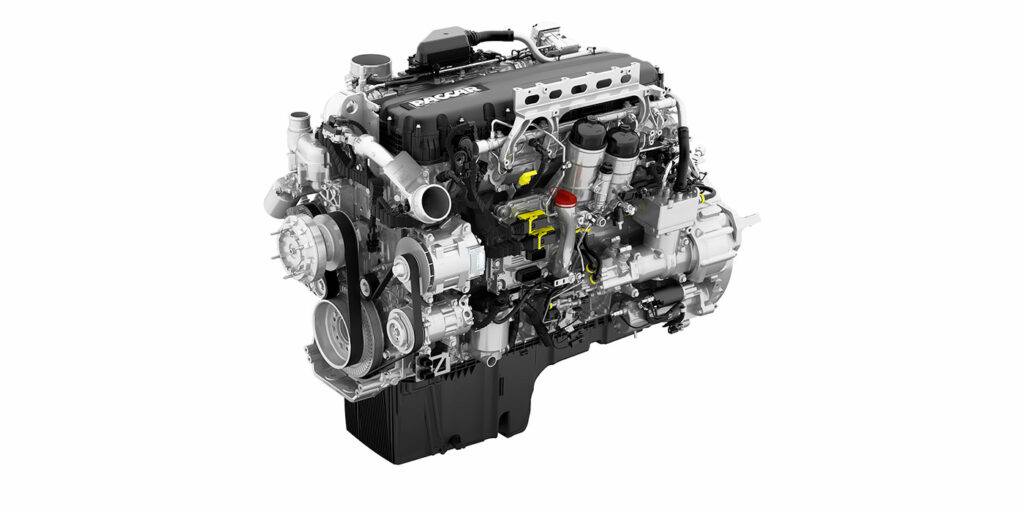

“We’ve seen a trend in vocational applications switching to smaller block engines to save tare weight in order to maximize payload,” says Hank Johnson, Kenworth general sales manager for vocational and medium duty. “For those fleets with weight sensitive applications, an 11-liter engine can save several hundred pounds, offer an excellent power-to-weight ratio in a compact package, and deliver the same performance as a larger engine. Also, while it’s typically assumed that a larger engine will outlast a smaller engine in the same application, that isn’t the case when engines have been tested and held to the same design life expectancy under identical conditions.”

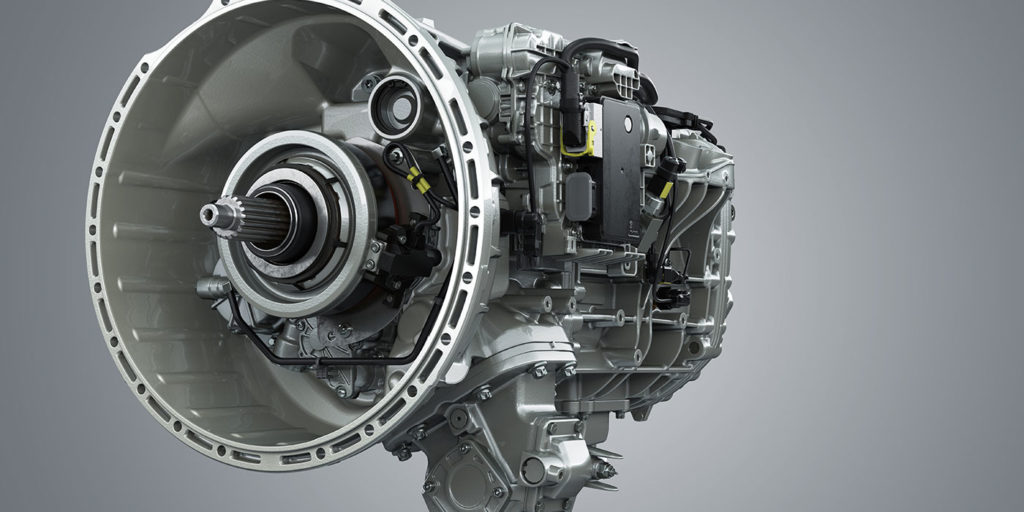

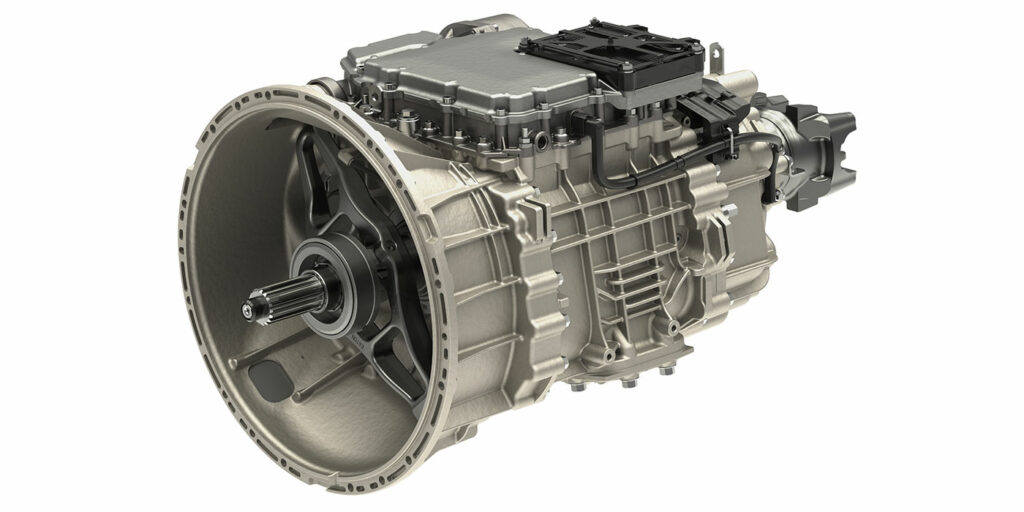

Today, the level of integration between the engine and transmission is impressive, points out Ken Rocker, Endurant XD series product manager at Eaton Cummins Automated Transmission Technologies. “They work together seamlessly to ensure optimal fuel efficiency, power and performance,” he says. “A lot of time is spent developing transmission calibrations paired with an engine’s torque curve to optimize performance.”

Rocker also relates what the company asks fleet customers in order to properly spec transmissions:

- How important is low speed operation? The challenge for many applications is the need to optimize highway and jobsite operation. First gear or crawler gear ratios along with the axle ratio will determine the minimum sustainable creep speed, while the overall ratio of the transmission will determine the highway cruise performance.

- Will the truck need to operate frequently in reverse? For short distances (under 50 yards), one to two reverse speeds will probably suit the application, but for longer distances (over 500 yards) or applications with deep axle ratios, fleets should consider spec’ing transmissions with a higher number of reverse gears to increase reverse vehicle speeds.

- What road conditions will the truck operate in? Different road conditions will impact the time spent in different gears of the transmission and is one factor is spec’ing the correct powertrain. Soft soil and off-road conditions can also increase the frequency of shock loads on the driveline.

- What is the max GCW? Overall, the vehicle’s Gross Combination Weight will affect your transmission choice.

- What types of grades will the truck operate in? Closely linked to GCW, significant grades increase the need for wider ratio transmission specs (to increase first gear startability by running a deeper axle ratio) and the need for smaller step sizes between the gear ratios to ensure shifting on grades.

- What kinds of accessories, such as PTOs, auxiliary transmissions, etc., are needed? The power capacity and number of PTOs needed will narrow the transmission search. Some applications can require an auxiliary transmission behind the main transmission or the use of two-speed axles. These multi-speed drivelines can increase the available gearing options beyond the primary transmission for in-frequent heavy loads and/or steep grades where a fixed ratio conventional driveline cannot cover all driving scenarios, such as interstate driving while unloaded vs. high GCW maneuvering on a job site.

The manufacturers interviewed for this piece all report that they are ready to help fleets make the right powertrain choice. “The goal when designing vocational engines and transmissions is to develop, test and release rugged and tough componentry that shows up for work at the jobsite each and every day,” Detroit’s Len Copeland says.