When a truck is idling it burns approximately 0.8 gallons of fuel per hour. At today’s average cost of diesel fuel of $3.04/gal., a truck idling for 10 hours will cost approximately $24.32. Multiplied over hundreds of trucks and the costs escalate quickly.

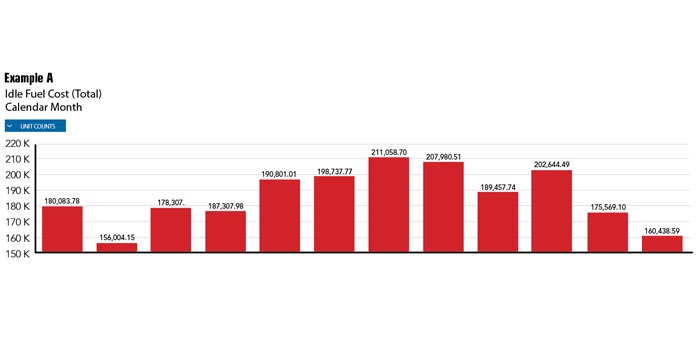

As shown in Example A above, fleets begin to see spikes in idle percentage starting around May and going through August. This can result in an increased burden on a fleet’s bottom line. Argonne National Laboratory, a multidisciplinary science and engineering research center, estimates that here in the U.S., rest-period truck idling consumes up to one billion gallons of fuel annually at a cost of around $3 billion.

Argonne further estimates that rest-period idling results in the emission of about 11 million tons of carbon dioxide, 55,000 tons of nitrogen oxides and 400 tons of particulate matter annually in the U.S.

These levels are alarming, and also represent a major reason as to why transportation fleets are changing their mindset in how they manage the lifecycle of trucks today. They are paying closer attention to fuel costs, as well as utilization rates, finance costs, maintenance and repair, which are all factored into a truck’s TippingPoint: the point at which it costs more to operate a truck than it does to replace it with a newer model.

Case in point: fleet operators can realize a first-year per-truck savings of $16,928 when upgrading from a 2015 sleeper model-year truck to a 2020 model. For a fleet of 100 trucks, when upgrading to a 2020 model year the savings can reach $1.7 million. These cost savings are only achieved when adopting a shorter asset lifecycle.

These costs are further exacerbated the more a truck idles during the hot summer months. What’s more, many states have idle restrictions in place that can penalize drivers and fleets with hefty fines if caught idling for an extended period of time.

On top of the expanded fuel costs and environmental harm caused, engine idling also increases wear and tear on engine components and can lead to costly aftertreatment expenses. The more hours an engine is running, the harder the aftertreatment system must work to keep the exhaust clean resulting in faster wear on aftertreatment components.

Engine oil and coolants can be impacted by heat, and service technicians will want to make sure oil levels are properly maintained since it provides lubrication to engine components and also helps keep the engine itself cool. The engine radiator, EGR coolers and transmission cooler also must be well maintained to keep adequate engine and transmission temperatures.

Fleets should also work with drivers to ensure engine idle shutdown settings are enabled and working properly. Many fleets set their idle shutdown settings to five or even three minutes, where the engine will shut down after a tractor has been idling for the pre-determined amount of time.

Lastly, fleets may want to consider purchasing auxiliary power units for sleeper tractors to help curb idle percentage times. These are external engines that operate the HVAC in the cab, and the engine is more efficient than the main powerplant of the tractor. It is estimated that auxiliary power units can save one tractor up to 2,500 gal. of diesel each year.

Travis Wynes, CTP, is director of fleet services for Fleet Advantage.