Cooling systems on fleet vehicles get a lot of attention these days. High-tech coolants are available from a wide variety of sources, and each claims to be the solution to whatever problem your engine is facing. Coolant analysis can help fleets maintain the proper chemical composition of the coolant.

Cooling systems on fleet vehicles get a lot of attention these days. High-tech coolants are available from a wide variety of sources, and each claims to be the solution to whatever problem your engine is facing. Coolant analysis can help fleets maintain the proper chemical composition of the coolant.

In fact, according to some experts, improper cooling system care may be the cause of about 40% of premature engine failures. But, if you think you’re doing your vehicles justice by checking coolant level and conditions at every PM inspection, think again. You may be neglecting an often overlooked, but critical, part of the truck’s cooling system—the fan clutch.

Understanding the fan clutch

“The technology in the commercial truck industry as it relates to fan clutches is very mature,” says Jim Benson, applications engineering manager at Borg Warner. “However, we’re facing the realization that not everybody understands fan clutches and how they operate.”

In a nutshell, a diesel engine must operate within certain temperature parameters to be most fuel efficient. Cooling the engine is always a concern; so cooling fans have traditionally been used to turn on when needed, helping to draw excess heat from the engine compartment.

However, since 2007 when new EPA emissions regulations began producing the unintended consequence of higher heat in the engine compartment, increased attention has been paid to the design and operations of the fan clutches available at the OE level.

Dissipating heat

“There are a variety of issues fleets must consider with fan clutches, but the main issue we’re seeing today with the later model post-’07 engines is greater cycling of the fan drives and longer run times,” explains Tom Hujik, director of North American Aftermarket Field Sales for Horton, Inc. “Unfortunately, heat under the hood went up significantly. Excessive heat is bad for all underhood components. Power steering pumps, air compressors and alternators have all been affected by this increased heat. Fifteen years ago 5% run time was typical of a fan drive. Now, it’s closer to 30% on-time and significantly higher for vocational trucks. Cycling and on-time leads to wear whether it is an on/off or variable speed fan drive.”

Hujik says another culprit under the hood with post-’07 engines is the excessive cycling of the fan due to the air conditioning system requirements. “There is a TMC recommendation regarding fan on-times for A/C units,” Hujik explains. “In other words, when the A/C system engages the fan to cool the condenser, it should be on a minimum of 60 seconds, which gives ample time to reduce the head pressure in the system. Straightforward enough, except for one problem, Hujik added. “All the ECMs from the factories should be programmed this way—many of them weren’t. We’ve seen a significant number of trucks that were set at 0 seconds, meaning the clutch would just sit there and chatter the whole time. That’s a sure way to wear the lining out quicker.”

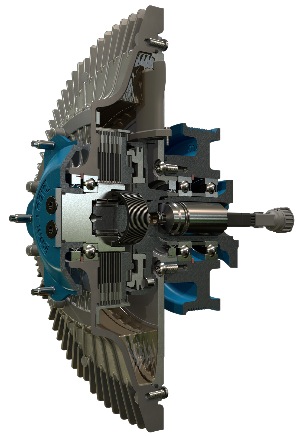

Hujik explains that all of these difficulties challenged the manufacturers to develop a more effective solution. “So through all that, the idea came about that since we have higher on-times, why not have a low-speed to take care of that kind of demand?” he says. “In a lot of cases, when there’s no ram air driving down the road, such as with a stop-and-go type application like a garbage truck, the fan wouldn’t need to come on, because the low speed would satisfy most cooling requirements without engaging to its full on mode. This style also provides fuel savings, reduced fan noise and increased belt life in these types of applications.”

This cycling issue isn’t exclusive to just one manufacturer, according to our experts, but is in fact a pervasive problem for all fleets.

But while cycling concerns are recognized across the industry, Borg-Warner’s Benson says the rush to do something about them hasn’t been universal. “Some of the OEs were quick to embrace the variable speed technologies, where others relied on the on-off system and continue to have it as their standard offering. Only the Volvo Mack group offers a variable speed product as its standard product, but allows fleets to specify an optional on-off.”

Variable speeds are more expensive initially, Benson is quick to point out. In fact, even at Volvo/Mack where the variable speed fan is standard, if you spec an on-off unit, you get a credit. “They’re designed for longer use—you should expect to see twice the life out of a variable speed than when you would have to service an on-off drive. You’ll get the same life if you do the service, but you also have to maintain it,” Benson explains.

Along with increased service life, both of our experts agree that variable speed fan clutches offer a host of other benefits.

“Demand for power under the hood has gone up,” acknowledges Hujik. “And through the years, we’ve always tried to stay ahead of that with bigger fan blades and bigger radiator packages; we’ve got a little respite now because we’re finding the SCR technology has not added any more heat than the previous generation.

Benson agrees. “All the other auxiliary components that interact with the fan drive—the whole drive belt system—live longer. You get better life out of tensioners, idler pulleys, out of belts. You don’t have to change the belts as frequently. And you don’t get the large thermal swings with your radiator and charge air cooler with a variable speed product that you do with an on-off. Your fan starts coming on and your coolant may never get to 212º because you brought the fan on before that. You maintain a more reasonable temperature—you don’t have those huge temperature spikes in your heat exchanger, either. You get some longevity out of the other components that help you cool.”

In addition to smaller, hotter running engines, today’s fan clutches face another, perhaps unexpected, challenge. “Modern aerodynamics mean the trucks don’t slow down as well on their own—rolling resistance is less, so drivers rely more and more on an engine retarder to slow that vehicle down,” says Hujik. “There is a parameter in most ECMs as well that turns the fan on when you turn the retarder brake on. If you do that, the drive is not being used in a manner in which is was intended and induces more wear.

Robbing horsepower is often a goal but can be a curse as well, says Benson. “On-off products take a lot of horsepower when they come on—in the range of 60-70 HP. All that drain of the power from the engine often causes the driver to downshift to get back into a range in the engine where they have higher power. So having an on-off can often require more frequent shifting to maintain speed. For a guy running a manual transmission, that’s significant.”

When vehicles aren’t equipped with the correct components, unintended consequences mean accelerated wear out on other parts including seals and friction material. Servicing on-off fan clutches is a necessary part of a fleet manager’s responsibility.

Maintenance is required on a normal over-the-road fleet. Hujik recommends inspections at PM intervals where the units are checked for air leaks, discoloration, belt tension and liner wear; and then major overhauls at around 500,000 miles.

Variable speed fan clutches don’t have replaceable wear items, and that’s the difference. They’re designed for longer use—you should expect to see twice the life out of a variable speed than when you would have to service an on-off drive. You’ll get the same life if you do the service, but you also have to maintain it, Benson says.

Under-appreciated components?

“I think fan clutches are a little under-appreciated as to how much they interact with the whole vehicle system,” Benson says. “If you have belts that wear out or tensioners that are breaking, or have high-ratio and high-torque fans that are required for very high heat rejection we find in today’s trucks, putting a variable speed unit on can help with much more than maintenance or just getting more life from the clutch. There are all sorts of NVH, driver retention and auxiliary component benefits. It does so much more than just keep your truck cool. Well-designed fan clutch can do a great many things.”

Hujik echoes these feelings and says whether it’s an on-off fan clutch, an eddy current two-speed version, or variable-speed design, the key is to have the proper unit. “Spec the truck right to begin with: if it’s an on-highway vehicle, you can continue to run an on-off fan drive and not have the slip and horsepower drain of a variable-speed drive. If it’s a vocational vehicle or anything that isn’t 80% on-highway, I recommend a multi-speed clutch.”

Either way, you have several options for keeping your cool. There is also the option of converting an existing on/off fan drive to two-speed style with the simple installation of a conversion kit or a reman unit to achieve these same benefits.