Unplanned service events are a fact of a fleet manager’s life. They happen. And when they do, you have to be able to talk about the problem with your service provider—be it your own shop, a dealership or an independent provider. That means having the right data and understanding what it means.

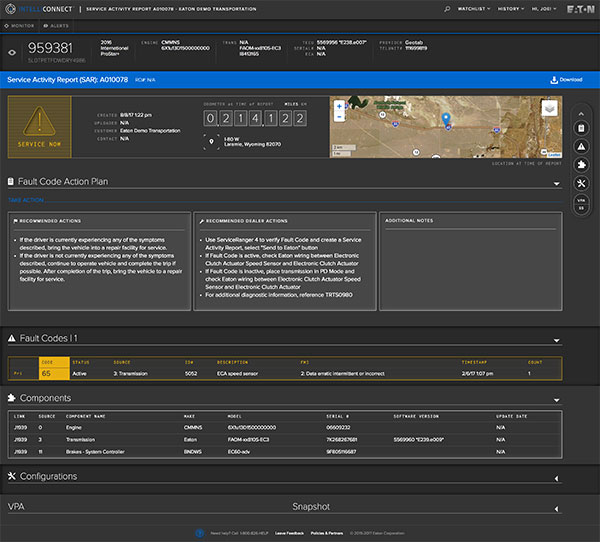

Having the right data means having all of the data. As the telematics landscape has evolved, component manufacturers are now offering portals into their proprietary data world. Take Eaton’s IntelliConnect platform, for example. It’s a transmission-focused remote diagnostics portal that integrates into existing platforms, such as those from Omnitracs and Geotab, to give you a window into not just specific transmission faults, but also how all the faults on the truck might impact the transmission.

“If a vehicle has an Eaton transmission in it, we want to see the body controller faults, the engine faults, the brake faults and the transmission faults because, being in the middle of all of those systems, the transmission can be easily affected,” said Bobby Robinette, manager of service solutions for Eaton. “It’s critical that we’re able to see all of those.”

That deep data insight is passed on to you, the fleet manager, via Eaton’s IntelliConnect complete with guidance concerning what to do next.

“Before that truck arrives at a service center, IntelliConnect gives you the information to let them know what fault codes may be coming,” said Robert Green, Eaton’s manager of digital engineering. “I’ve heard stories in which service providers have been able to complete the triage process remotely and, in one case based upon the IntelliConnect information, a technician met the truck in the parking lot at the dealership, swapped out a component and got the truck right back on the road within a matter of minutes to deliver an important load.”

Every load is important in today’s highly competitive freight environment. You need every advantage you can get, and manufacturers like Eaton know that means going beyond manufacturing top-notch hardware; it means transforming the data into actionable information.

“At this point, we tell service providers the troubleshooting procedure, and then we start giving guidance,” Green explained. “We’ll say, ‘Look, five components on the vehicle complained about a power issue, whatever you do don’t replace the transmission ECU. That’s not the root cause. Go look at the battery and look at the common wiring between all these systems.’ In the future, we definitely want to get to the point where we have online troubleshooting procedures that can adapt to the situation, and remove parts of the procedure we know aren’t the problem, streamlining the overall repair process.”

Of course, there’s a catch—the data isn’t going to act for you. You have to engage with the platform, understand what it’s telling you and then pick up the phone and execute the service plan.

“Fleets may hesitate to dive into the data because they think that it’s going to be a complicated process to get connected,” Robinette said, “but it’s really easy to get signed up with IntelliConnect.”

“That’s right,” Green agreed. “Once you enable the system it basically turns the faucet on to the data and it just starts flowing. We learn new vehicles automatically as the data comes into IntelliConnect, which means there’s very little setup required.”

Once that data faucet is flowing, Eaton stays connected with you to help you through the execution of the service plan. The IntelliConnect data helps inform Eaton’s Roadranger network—a crack squad of experienced, accessible drivetrain consultants that can help you work with your service provider and get your trucks back on the road.