With more technology being integrated into the daily functions of fleets, it can be hard to find the time and the best training methods to ensure that your staff is properly equipped to service your equipment assets. While technology is a factor creating this dilemma, it is also the solution. Virtual training in all aspects of fleet management and maintenance is a new way to train your technicians.

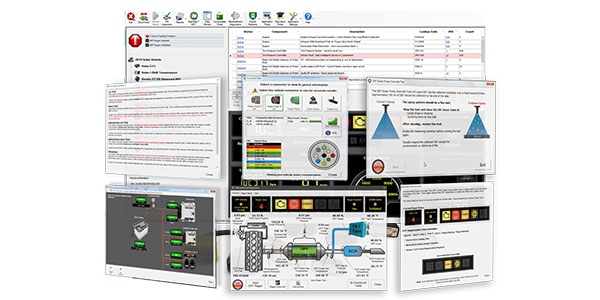

At the forefront of the virtual training game are companies like Noregon. In March, the company announced its first major 2018 update of its in-shop diagnostic and repair solution, JPRO Professional 2018 v1, which includes major virtual features such as an education portal, a virtual truck for hands-on learning and increased bi-directional tests.

“We believe strongly in improving a technician’s skill set so he or she can improve in-shop efficiency,” said Jason Hedman, JPRO product manager for Noregon. “Not only does this directly result in improved profits for a repair facility and increased uptime for vehicle owners, it also empowers fewer technicians to complete more work and be more efficient, helping address concerns around the technician shortage.”

Using a new educational portal, technicians have access to an extensive library of training videos, sorted by topic, where users can learn the intricacies of the software when needed. Additionally, the portal also includes four training webinars a month, where techs can ask a Noregon product expert their questions.

This virtual education tool can help bridge the gap between technicians and fleet managers. Through JPRO certification, technicians can prove their abilities on a tool commonly used by the largest fleets and repair facilities. Once certified, technicians earn patches to sew onto their work uniform to display their proficiency and assure employers they are properly trained and qualified.

“The benefit to fleets is having a tangible method to measure their technicians’ skillsets,” Hedman said. “By employing technicians capable of working on all makes, models and components in a single application, fleets save money from increased uptime as a result of quicker and more thorough repairs. Rather than using singularly focused OEM software to diagnose component-by-component, JPRO certified users are comfortable connecting with one tool to holistically diagnose and repair the entire vehicle. It can be difficult for a fleet manager to understand exactly how skilled or qualified a technician is. Programs like the JPRO certification course bridge this gap.”

Noregon also made sure technicians can continue to virtually work on trucks to hone their skills and troubleshoot a virtual truck feature. Using Noregon’s virtual truck, users can simulate the regen, or other bi-directional tests, without the limitations or liability concerns of performing them in the real world.

“Because JPRO is an all makes, models and components solution, the application presents the same interface and experience regardless of which brand of vehicle the user is connected to,” Hedman notes. “By using the virtual truck as a training tool, users have a repeatable, controlled environment to prepare for a situation commonly experienced in the field.

“If a student learns JPRO in the classroom by using the virtual truck,” Hedman continues, “he or she can be prepared to walk into the shop at any heavy-duty dealership with the skills needed to diagnose, troubleshoot and repair any vehicle brand.”

With a future in virtual training, Noregon has more virtual truck configurations planned to improve the training options for automotive students and fleets.