“Location, location, location” is a well-known real estate industry mantra; in the fleet world, we can change that to “application, application, application.” There’s no part or component on the truck that isn’t affected by the application the truck runs in, and this should be the first thing on any fleet manager’s mind when spec’ing a new part. Let’s go over some of the key application considerations for steer axles.

“Knowing where and how the truck will be used will help design the truck for proper load distribution and mitigate axle overload situations,” Brian Daniels, manager of Detroit powertrain and component projects, says of steer axle applications.

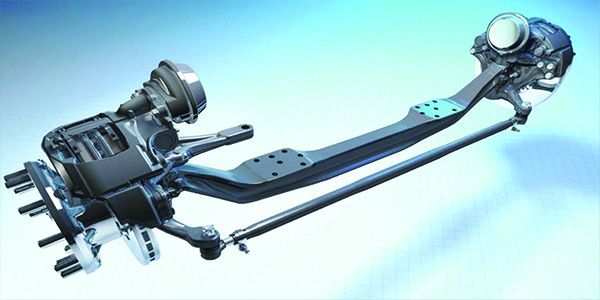

Harry Trost, senior manager of product planning with Dana, lists track width, beam drop, turn angle, maneuverability, weight and disc brake compatibility as the most important points for fleets to know before they begin the axle spec’ing process.

To zero in on a specific example, many fleets will have to take the steer angle offered by their axles into account, as high-angle capability is important for certain applications.

“Maximizing turn angle is a key consideration for commercial vehicles,” Dana’s Trost says. “Many applications often require enhanced maneuverability to get into and out of loading docks for Class 8 tractors, navigate residential neighborhoods for refuse and school bus, and even navigate twisting narrow roads for logging and mining applications. Dana Spicer steer axles offer turn angles up to 55 degrees to maximize maneuverability.”

Detroit’s Daniels notes that his company’s steer axles also offer a 55-degree turning radius, ensuring maneuverability in tight situations in the city or on the job site.

“The tight turning radius on vehicles equipped with Detroit steer axles minimizes the need for multipoint turns including reversing in tight spaces,” he says. “Reducing the need for multi-point turn maneuvers improves safety—it reduces blind backups—and efficiency.”

How brakes work with steer axles

Integration is always a focus when it comes to truck components, but this is especially true for steer axles, which work closely with the brakes and tires. This means that, when spec’ing axles in each position, you need to be especially aware of what equipment will be used throughout the truck and how it all fits together.

Dana’s Trost notes that steer axles need to be compatible with both drum and disc brakes. This should come as no surprise—drum brakes are still the tried-and-true option and represent a significant majority of the brakes on the road today, but air disc brakes are on the rise and have been increasing in popularity for years now.

Trost singles out Dana’s D-Series integrated air disc brake steer axle, which is available through multiple truck OEMs, to support air disc brake installations on 10,000 lbs. through 14,600 lbs. GAWR applications. Trost went on to point out that the air disc brake steer axle can be equipped with either disc brakes or drum brakes. Either way, he says, “steer axle installed air disc brakes offer extended maintenance intervals for pad replacement and better stopping performance for commercial vehicle applications.”

Tire options for the steer axle position

One option that might be worth considering in certain applications is retreaded tires for the steer axle position. You just have to make sure you are using the highest-quality retreads possible, as steer axle tires are subject to even more stress and road wear than any of the other tires on the truck. Vocational trucks, urban delivery trucks, and others that are back at the base every night and can have the tires frequently inspected are good candidates for retreads on the steer axle position.

This is borne out in the Federal Motor Carrier Safety Association (FMCSA)’s “Industry Recommended Practices for Tire Retreading & Tire Repairing,” which states that in local service applications, like those mentioned above, the tire may be retreaded more than once. However, the document specifically bars a previously retreaded tire being used on a long-haul truck in the steer axle position—this is a solution only available to urban, vocational and other similar applications.

Maintenance factors

As for steer axle maintenance, first and foremost it’s important to keep the axle’s recommended maintenance intervals, and the warranty that’s offered with purchase, at the top of your mind.

Detroit’s Daniels says that the company builds its steer axles with a low-maintenance result in mind. For instance, he notes, “when greasing the zerk fittings, there’s no need to tie up a service bay to lift the truck off the ground. Greasing can be done while the truck is on the ground and loaded due to the use of needle bearings instead of bushings. Needle bearings allow the grease to easily pass through and lubricate the kingpin components. This allows preventative maintenance to be performed quickly and returns the truck and driver to the job at hand.”