Daimler Truck North America (DTNA) debuted the Freightliner SuperTruck 2, showcasing features that are designed to deliver the next level of freight efficiency. As part of the SuperTruck program co-funded by the Department of Energy (DOE) with the aim to reduce emissions from on-road freight transportation, DTNA engineers were able to investigate next-generation technologies for heavy-duty commercial trucks and to clear the technical pathway for their development and potential integration into series production. Focus was on developing new technologies on the most promising core components and systems to improve the real world operational efficiency of the truck to help make customers more successful and increase fleets’ operation efficiency.

Building on the the first SuperTruck, which overachieved DOE requirements in 2015, SuperTruck 2 surpassed expectations in aerodynamics, tires, powertrain and energy management, while doubling the freight efficiency of the base vehicle from the start of the SuperTruck program.

Freightliner engineers noted the four key areas of the SuperTruck 2 development: aerodynamics; powertrain; rolling resistance; and electrical system.

Aerodynamic improvements

In close collaboration between the design and engineering departments, the teams were able to overachieve in aerodynamic improvements and reduce the aerodynamic drag of SuperTruck 2 by more than 12% over SuperTruck 1 according to studies conducted by DTNA. Instead of radically changing the structure of the truck, the design goal for SuperTruck 2 was to redefine the existing shape of the Cascadia to maximize aerodynamic efficiency and simultaneously employ advanced design language to convey that efficiency.

According to Jeff Cotner, chief designer, DTNA, the goal was to maximize freight efficiency while also creating an attractive truck without making unnecessary changes. The redesigned hood, bumper and chassis fairing all work well with the existing cab structure and now allow the air to flow undisturbed around the truck. The grille, air intakes and doors were redesigned to be as seamless and clean as possible; no sharp edges compromise the aerodynamics or beauty of the truck. Other areas were refined in an iterative approach between the design studio and engineering team. Active side extenders and a roof spoiler system closes the trailer gap by up to 4 inches at highway speeds and an enhanced Aerodynamic Height Control lowers the truck just inches off the ground for additional aerodynamic improvements.

Thanks to federal exemption by the National Highway Traffic Safety Administration (NHTSA) for the program, by removing the exterior mirrors and integrating a mirrorless camera system from Stoneridge, the aerodynamic drag of SuperTruck 2 was significantly reduced. The cameras have been tested under all weather conditions and have shown great promise in enhancing the driver’s visibility and improved vehicle safety, which supports advocacy for future regulatory changes that would permit the widespread adoption of this advanced technology by manufacturers.

Powertrain technologies

The updated powertrain enables a 5.7% fuel consumption reduction over SuperTruck 1, according to the company. With a non-certified prototype Detroit 13-liter engine featuring two-stage turbo and interstage cooling and a 13-speed overdrive transmission, the powertrain is able to achieve lower downspeeding and greater fuel savings through reduced drag overdrive.

One key powertrain feature of SuperTruck 2 is split cooling. This system consists of high temperature and low temperature cooling circuits, working in tandem with two-stage turbocharging and exhaust gas recirculation (EGR) cooling on the engine. Together, these technologies result in further efficiency gains enabling more aggressive downspeeding. A smart engine lubrication circuit minimizes internal pumping losses, thus reducing engine parasitics by actively proportioning flow to the most sensitive components.

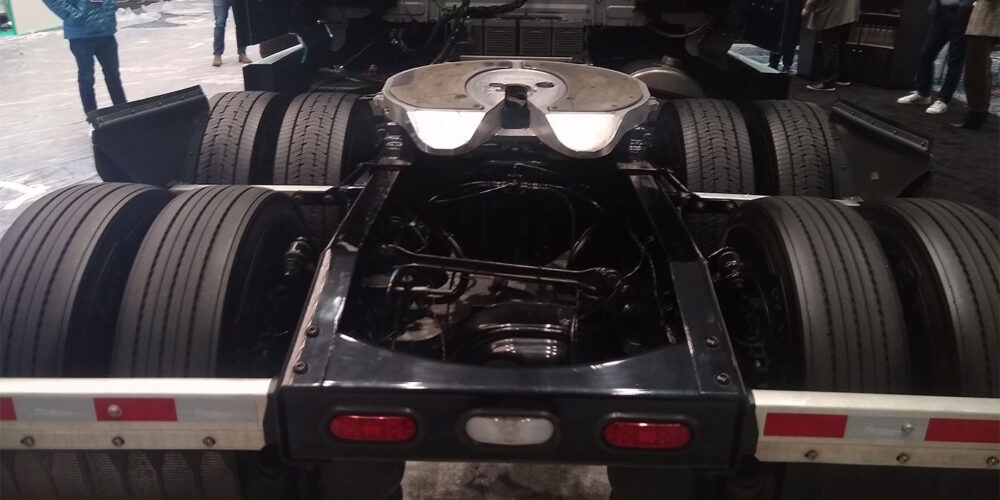

According to DTNA, through the implementation of adaptive tandem axles, it allows for increased torque from the fuel-efficient powertrains and automatically shifts from 6×4 to 6×2 at highway speeds which benefits the driver when maneuvering in low speed.

Low rolling resistance tires

DTNA again collaborated with SuperTruck 1 partner Michelin on the development of brand new tires specifically designed for adaptive tandem axles to not only reduce vehicle energy consumption but also to reduce maintenance downtime due to minimized wear and tear on the tires. By lowering the friction on the road, less fuel is needed to maintain the truck speed. The engineers were able to significantly reduce the tractor rolling resistance by 12% over SuperTruck 1.

In co-development with DTNA, Michelin designed tires specifically for the steer, drive and tag axles on SuperTruck 2. The introduction of dynamic load shift further increases efficiency and fuel savings. With this technology, some of the load will be shifted automatically from the drive axle to the tag axle to take advantage of the tag tire low rolling resistance. The overall design of the new tires included development of new treads and compounds that translated into more than 20% improvements in drive tire wear and tear and overall significantly improved rolling resistance.

Energy management

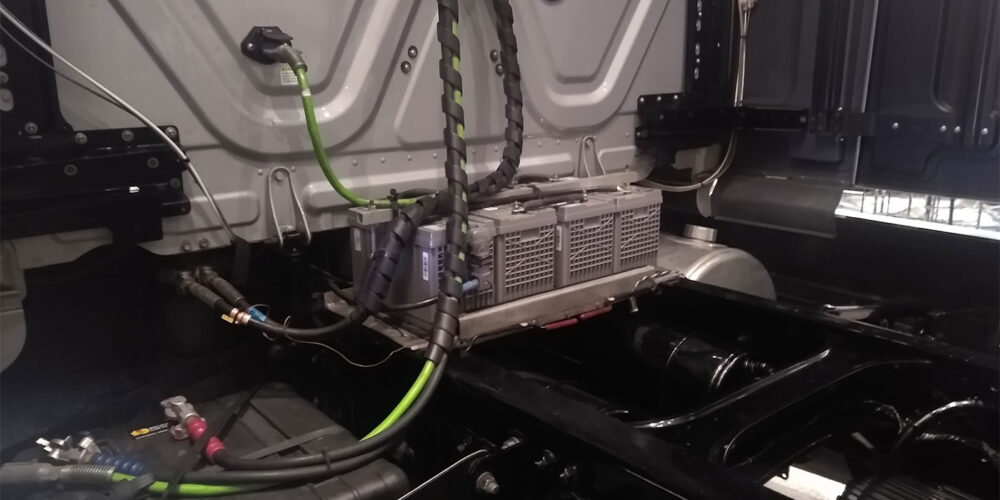

SuperTruck 2 features a 48-volt electrical system with lithium-ion batteries, enabling a new electric steering system to adjust demand as needed, whether the operator is maneuvering at low speed or driving at highway speeds, or to operate during EcoSail while the engine is off.

The EcoSail feature can turn the engine off when drive power is not needed, without requiring any intervention from the driver. At the same time, if the truck is coasting down a hill while the engine is off, features like air conditioning remain in operation. As soon as power is needed, the engine will restart automatically for a seamless experience for the driver.

More 48-volt features result in decreased fuel consumption and increased driver comfort like a new electric air conditioning system that consumes 50% less energy than SuperTruck 1 and continues seamless operations while the engine is turned off.

A new 48-volt starter turns on the engine with more power and speed. Finally, the new 48-volt electrical system operates the hoteling features without the engine running while delivering 12- volt power for the standard cab items like lighting or the instrument cluster.

The SuperTruck trilogy

DTNA has also been awarded a grant for SuperTruck 3 to develop a hydrogen fuel cell electric tractor that exceeds heavy-duty long-haul sleeper performance, efficiency, and range requirements without compromising payload. SuperTruck 3 designs are planned to be revealed by 2027.