Cummins

The official quote: “Cummins isn’t introducing new technology to meet 2021 emissions. Instead, we’ve been able to optimize our current technologies to continue to deliver efficiencies and performance while still meeting emissions standards.”

—Kris Ptasznik, Cummins heavy-duty product manager.

Improvements within its latest engine release (to name a few):

- Increased compression ratio for improved combustion efficiency provide increased cylinder pressure to help drive the piston down;

- Hardware optimization for reduced parasitic losses; and

- Software changes for improved combustion and new feature content for drive cycle fuel savings.

- Integrated Powertrain offerings pairing the Endurant transmission with look ahead features to provide exclusive features in the EX package like on-ramp boost and predictive engine braking.

The 2020 X15 Efficiency Series base engine hardware improvements and advancements in air handling deliver up to a 3.5% better fuel economy when compared to the 2017 X15 Efficiency Series engine model, meeting 2021 requirements a year in advance with the same improvements coming to the Performance Series at the 2021 launch, Cummins reported. The 2020 Productivity Series offers ratings designed for multi-purpose, vocational and heavy-haul customers.

Detroit

The official quote: “At NACV, Detroit showcased the enhanced Detroit DD15 Gen 5 engine [available 2021]. Updates for the next generation engine will allow for more efficient combustion which will contribute to greater fuel economy and reduced C02 emissions. The result is a fuel economy gain of more than 3% – with additional gains possible when the truck is equipped with an integrated Detroit powertrain.”

—Brian Daniels, manager, Detroit Powertrain and Component Product Marketing

In the new DD15 Gen 5, ultra-high compression ratios paired with a new swirl piston design make combustion even better, according to Daniels. A few other components that are enhanced within the DD15 Gen 5:

- A Ball Bearing Simple Geometry Turbo that Daniels said allows peak power and torque to be reached faster;

- Turbocharger;

- Engine brake;

- Vocational ratings and new ratings with higher torque; and

- Increased compression ratio.

There are also enhancements coming to the DT12 transmission in 2020. According to the OEM, these include higher overall ratios that will contribute to fuel efficiency improvements and provide better low-speed maneuverability, and new side power take-off capabilities that allow increased flexibility and expanded application coverage.

International

The official quote: “Fuel economy continues to improve, up to 8.2% for the 2021 Model Year International LT Series vs. the beginning of the 2020 Model Year. Predictive cruise control is standard, and its fuel economy benefit has been further improved for the International A26 and for the Cummins X15.”

—Jim Nachtman, heavy-duty marketing director, Navistar

Enhanced aerodynamics, and new aerodynamic options, on the LT Series and RH Series continue to boost the fuel savings bottom line, according to the OEM.

Aerodynamic advances offered for 2020 include (continued on the next page):

- Enhanced roof fairing

- Day cab extenders that are 12 in. longer, closing the tractor-trailer gap

- Sleeper cab extenders are 3 in. longer, reducing the tractor-trailer gap

- Steering wheel closeouts around the front tires

- Longer chassis skirt Vidon strips, which enhance aerodynamics and are damage resistant

- New cab-to-skirt closeouts to further reduce wind drag

- 1 in. lower bumper valence

- FlowBelow 2.0 design, optimized for the International LT Series

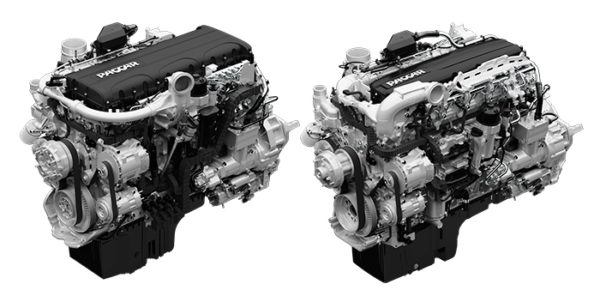

PACCAR

The official quote: “The Greenhouse Gas Phase 2 standards that go into effect in 2021-27 call for substantial efficiency improvements, while Ultra Low NOx regulation will require significant reductions in tailpipe emissions. At the same time, our customers rely on our engines for their business and we recognize that uptime is paramount.”

—Carl Hergart, director of powertrain and advanced engineering, PACCAR Technical Center

Peterbilt Motors Co. and Kenworth Trucks both announced over-the-air updates for model year 2017 PACCAR MX-11, MX-13 engines with a SmartLINQ subscription and Kenworth TruckTech+, respectively. In Peterbilt’s case, the technology will leverage the existing SmartLINQ Remote Diagnostics hardware and the PACCAR Solutions portal, along with a new mobile app, to deliver secure software updates remotely. Fleets are able to request the software updates via the PACCAR Solutions portal. Over at Kenworth, The PACCAR Solutions portal provides customers with visibility to all their Kenworth trucks, truck performance data, and shows those trucks requiring updates, the OEM announced. Once the customer approves the update, the vehicle’s software update package is automatically built and the customer receives an email when the download is ready for installation.

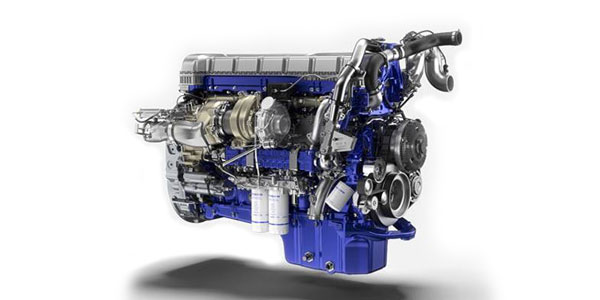

Volvo Trucks North America

The official quote: “Volvo Trucks North America is introducing the next generation of its Turbo Compound technology. This new D13TC further increases fuel efficiency by up to 3% over the current D13TC engine, saving approximately $1,200 per year per truck, based on the average fuel price and 125,000 miles per year.”

—John Moore, product marketing manager at Volvo Trucks North America

The revised wave piston, designed and patented by Volvo Trucks, is also raising the efficiency bar. The improved design optimizes wave technology to evenly distribute the air/fuel mixture in the cylinder, burning the fuel more consistently than a traditional piston.

“The wave piston allows us to make better use of fuel that’s wasted in the late stages of combustion,” Moore explained. “That fuel doesn’t have a chance to mix with air and burn, and so it typically burns most of the air around the edges of the cylinder. The wave piston forces the fuel air mixture to circulate more to the center of the cylinder and burn it all.”

For more on this topic, click here to read 2021 model year diesel engines: What you need to know.