Conal Deedy sits in a dramatically lit conference room within the Volvo Trucks Customer Center. Spotlights shine on technology innovations past, present and future—from today’s over-the-air engine reprogramming to a rarely seen scale model of a Volvo concept truck. As Volvo Trucks’ director of connected vehicle services, Conal is Volvo’s foremost voice on all things connectivity. He leans back in a sleek white pedestal chair that wouldn’t be out of place on the set of 2001: A Space Odyssey, contemplating the question I just posed:

With thousands of possible fault codes that can be triggered and a remote diagnostic system that is capable of sending an email notification for each one, how do you make sure you’re providing valuable service information and not just spamming fleet manager inboxes with automated alerts?

“The information you provide has to be meaningful,” he begins. “From the beginning design phase of the ASIST system, we didn’t want to send out data on a fault code—that’s handing a problem to a customer. What we wanted to do was identify an issue and provide a solution to support our customers.”

Though technology is driving equipment trends from new truck designs to constant equipment communication, Volvo Trucks has invested heavily on the human side of innovation with its 123,000-sq.-ft. Uptime Center in Greensboro, N.C., which employs more than 170 employees who bring Volvo’s three integrated services—Volvo Action Service, ASIST and Remote Diagnostics—to life.

“We have to work together as a partner to get the best result and tailor the programs and structure to the customer,” Conal says. “That’s why we have people involved.”

It’s the same reason why I have pulled Conal aside during the busy launch of the Volvo VNX heavy-haul lineup, because at the end of the day, there’s nothing more valuable than talking with a real person about real problems. Technologies, including ever-evolving truck solutions, are merely a tool. It’s the data-driven hammer to pound more productivity out of your fleet, but a hammer doesn’t swing itself.

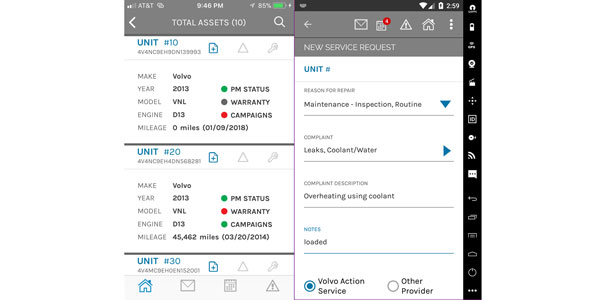

Conal explains that when a fault is triggered on a Volvo truck, the ASIST Service Management platform opens a case file based on the information the remote diagnostic system algorithm parsed through. It assigns a severity level, recommends an action plan based on established technician service trees and presents that information to a Volvo Uptime Center agent, who then contacts the fleet and walks the point of contact through the fault and the recommended service action.

“At that point, the fleet managers are the decision makers,” Conal says. “Many of our customers want control of the information—they don’t want to distract the truck driver with the issue. So we call them to provide insight into the fault, explain what the driver is probably seeing and share our service recommendation. Then they can call the driver, confirm what he is experiencing and communicate their service plan.”

Volvo applies that same technology strategy and people philosophy to its own service network—transferring the aforementioned case file to the service provider so that when the truck arrives and the QR code is scanned, all the relevant information will be displayed.

“The case file gives the dealership all the information they need to know to schedule the repair, ready the parts and even integrate into their service writer software and payment systems,” Conal says. “It’s hard to find good technicians in our industry right now, and you don’t want your best techs spending all their time diagnosing a truck that just shows up. But dealers put some of their best technicians on that job, and once they know what needs to be done, they pass the job down to a less experienced technician when it comes to turning the wrench. Having the information up front frees up expert diagnostic technicians so that they can spend more time doing what they’re really good at.”

Building smarter trucks and better solutions

Each step in the next iteration of truck technologies is neither a beginning nor an ending; it’s constant growth. It’s taking what OEMs learned today and applying it to a new solution tomorrow. As Conal talks more about the technology that is expanding into nearly every truck component, his smile grows wider.

“We’re just now starting to scratch the surface on what we can do,” he says through a full-on grin. “As the OEM, having the manufacturing and application knowledge and seeing the data means that we can translate that into actionable steps forward. Consider the configuration of a truck—I’m really excited about this. We can impact road speed limit and fuel economy performance with the right programming package from this room with over-the-air updates.

“It’s amazing what information is already coming off the truck,” Conal continues. There is no stopping him now; ambition and excitement have taken hold. I only hope that my typing keeps up with his imagination as it churns out the truck technology possibilities of tomorrow.

“We have ambient temperature sensors; we know the weather outside. In fact, we have thousands of sensors on the truck—good, bad or indifferent—and as technology has evolved not all the sensors were designed to do what we’re now asking them to do.

“So when we say we’re building the truck with connectivity in mind,” he says, “it sounds like a marketing line, but it refers to the sensors that are collecting information. Today, you’re seeing how new trucks glean even more information we need to improve the build for the next model down the road through new and more accurate sensors. If we can combine the truck’s history and application information, what can we do next?”

The “we” in that statement isn’t referring to automated systems or endlessly generated notifications. It’s people. The people who make the trucks, the people who service the trucks and the people like you, the fleets who operate, manage and depend on your equipment day in and day out. People have been and always will be the solution to our problems. Technology is merely the tool we use to fix them.