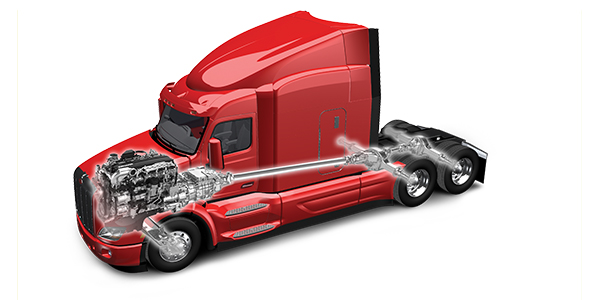

GHG Phase 2 regulations are coming in 2020, and while engines are the most obviously affected truck part, other components from the transmission to the suspension will be affected too.

Fleet Equipment reached out to ask transmission manufacturers how the upcoming standards will affect fleets’ transmission needs. One answer: powertrain integration will become more important than ever.

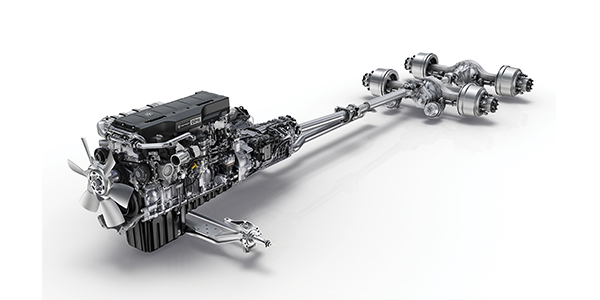

“The importance of powertrain integration cannot be overstated,” says Carl Hergart, director of powertrain and advanced engineering at the PACCAR Technical Center. “Even the most sophisticated transmission will not deliver the desired performance if not optimized with the engine, axle and overall vehicle as a system.”

John Moore, Volvo Trucks North America’s product marketing manager for powertrain, agrees. “Transmissions have become a key component in integrated drivelines, controlling how engines can run at lower RPMs for greater fuel efficiency and use available torque to maximize driver productivity while minimizing time spent at peak horsepower,” he says.

Most engine and transmission makers offer an integrated powertrain option, often including the axle, from truck OEMs such as Detroit, PACCAR, Volvo and Mack to the longstanding integration between Eaton and Cummins that resulted in the Eaton Cummins Automated Transmission Technologies joint venture, to name just a few examples.

Most engine and transmission makers offer an integrated powertrain option, often including the axle, from truck OEMs such as Detroit, PACCAR, Volvo and Mack to the longstanding integration between Eaton and Cummins that resulted in the Eaton Cummins Automated Transmission Technologies joint venture, to name just a few examples.

Integrated powertrains almost always feature automated manual transmissions (AMTs), which now possess an overwhelming share of the market across the trucking industry. The benefits of both AMTs and fully automatic transmissions will be intensified with the introduction of the new GHG phase.

“With GHG Phase 2, powertrain efficiency is becoming increasingly critical, driving increased adoption of automated transmissions over manual transmissions,” PACCAR’s Hergart says. “This is due to the increased efficiency of these transmissions combined with integrated features such as optimized shift points.”

According to Volvo’s Moore, the more stringent regulations will require improvements in fuel efficiency from the engine, transmission and exhaust aftertreatment system. Automated manual and automatic transmissions will provide GHG credits in Phase 2, he added, which will exert pressure for truck manufacturers to sell more AMTs and full automatics.

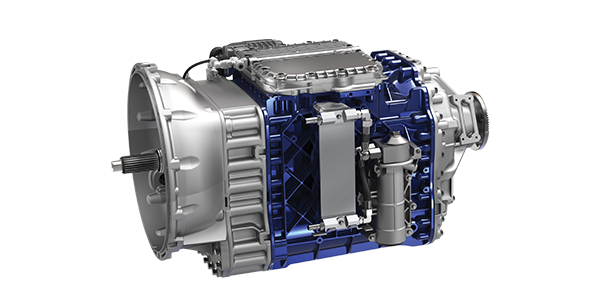

Brian Daniels, manager of Detroit powertrain and component product marketing, says that GHG Phase 2 will highlight the important of both AMTs and downsped engines. He calls out Detroit’s DT12 AMT, which he says is “an enabler for the entire powertrain to deliver efficiency increases and can further downspeed the engine.

“This,” Daniels adds, “is done through reducing losses, using improved and specifically formulated fluids, and creating more efficient shift maps that are dependent on the vehicle and application. The whole powertrain must work together to get these efficiency gains and the AMT is an integral part of the system.”

So: more integrated powertrains, and more automated manual and automatic transmissions. Sounds familiar, doesn’t it? No, neither of these trends is new, exactly—both powertrain integration and automated and automatic transmissions have been gaining market share at a rapid pace for years. But it does solidify that these trends are here to stay, and give fleets yet another reason to go with both.

Improving efficiency

Efficiency is key when it comes to meeting the new GHG standards—and, of course, with improving the bottom line, which is any fleet’s number one concern, regulations be damned. We asked the transmission manufacturers about technology on today’s transmissions that is improving efficiency, and they were all too happy to provide examples.

Efficiency is key when it comes to meeting the new GHG standards—and, of course, with improving the bottom line, which is any fleet’s number one concern, regulations be damned. We asked the transmission manufacturers about technology on today’s transmissions that is improving efficiency, and they were all too happy to provide examples.

PACCAR’s Hergart points to the improved architecture of modern AMTs as a good starting point.

“Modern automated transmissions tend to feature a twin countershaft design, which saves weight and improves efficiency,” he notes. “Lubrication is another key consideration, and designs that do without a cooler can gain significant efficiency. Controls are also becoming increasingly important. Technologies like neutral coasting and predictive functionality can deliver substantial fuel savings, depending on the route and application. For automatic transmissions—transmissions equipped with a torque converter—features such as neutral idle improve efficiency, especially in applications that require significant idle time.”

Detroit’s Daniels singles out four features of his company’s DT12 transmission that boost fleet efficiency:

- Skip shift, which increases shifting efficiencies and reaches cruising speed faster.

- eCoast, which allows the vehicle to coast down grades while the engine operates at idle speeds while maintaining momentum.

- Optional direct drive. The increased focus on downspeeding by using faster axle ratios with both direct and overdrive transmissions. Direct drive transmissions allow for greater top gear efficiency due to a one-to-one 12th gear ratio. Engine torque is transmitted directly through the transmission, reducing parasitic driveline loss and improving fuel efficiency.

- Intelligent Powertrain Management (IPM), which knows the route ahead and accelerates, preselects gears, eCoast and brakes to maximize efficiency. IPM adjusts shifting, engine torque output and engine braking level to achieve the greatest efficiencies.

Volvo’s Moore highlights the software improvements of today’s transmissions as a major step toward improved efficiency.

“Software on AMTs, like the Volvo I-Shift, includes fuel-efficient economy modes that allow skip shifting when less load is on the driveline such as flat to rolling terrain or lighter payloads,” Moore points out. “Top speed can be achieved in just four shifts. As load changes the transmission will revert to performance mode to maintain driveability and shift through every gear if necessary. Transmissions now connect with GPS to identify location to recognize terrain hills from memory and then climb most efficiently every time, knowing when to hold a gear or change one. The transmission is also using the engine fuel maps, horsepower and torque curves to decide best engine RPM to shift and optimize the gear selection based on driving conditions.”

Of course, efficient components are no good if the truck isn’t being driven in a way that optimizes its efficiency in the first place.

“With all the advancements in technology, design and spec’ing, the driver is still the most important variable when it comes to fuel economy,” Detroit’s Daniels says. “That’s why, in addition to spec’ing the right powertrain, driver training is critical to achieve optimal performance.”