The measurement of any well-run fleet is its budget. Creating and maintaining that budget is a major aspect of fleet management. Success is often measured by how well costs can be controlled or lowered. Though setting up a fleet budget is not always the most exciting task for a fleet manager, it is still important work.

Fleet management budgets not only help companies set financial targets for their operations, but also highlight areas for improvement.

By following a simple, step-by-step plan, fleet managers can minimize headaches and maximize the all-important bottom line. In this post, we outline all the details you need to know about creating a successful fleet management budget, including our four-step approach to building a budget for your fleet.

What are fleet costs?

Fleet costs, also known as total cost of ownership (TCO), include the various costs associated with buying and maintaining fleet vehicles. TCO is often something that many fleet managers overlook when making vehicle purchases, which can lead to overspending.

To properly calculate TCO, you need to factor in:

- The cost of each fleet vehicle including interest fees and taxes

- The return value of your fleet vehicles should you choose to sell or scrap them

- All of the maintenance and repair costs accrued over the lifespan of the vehicle

To learn more, read this blog post: How do you calculate total cost of ownership?

How does fleet management reduce costs?

Fleet management can reduce fleet costs through the monitoring and evaluation of vehicle and driver performance. When you optimize fleet performance with the use of telematics, you are likely to see a major financial impact on your fleet.

To reduce costs, you can adapt your fleet management strategy to focus more on cost savings strategies such as:

- Examining business costs

- Reducing risks to save money on insurance

- Building maintenance schedules

- Managing vehicle acquisition and disposal

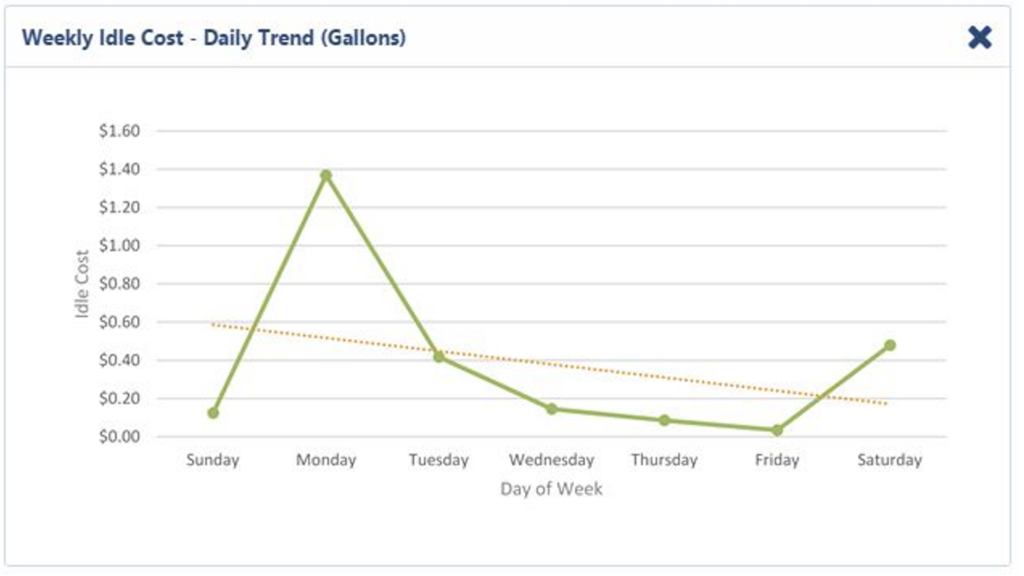

- Monitoring vehicle idling and fuel consumption

By monitoring existing fleet patterns, you can see solid indicators of future expenses and adjust your strategy to cut unnecessary costs. You can also track activity that isn’t expected and target trouble areas to increase efficiency.

Learn more about the cost savings associated with using telematics in: Managing fleet costs and finding savings with telematics.

How do you set up a fleet budget?

Building a fleet management budget doesn’t have to be complicated. By combining fleet data and previous operational insights together, you can find a simple way to outline your business expenses for the next year. To help you understand the building blocks for creating a fleet budget, we’ve created a simple, four-step approach:

- Set goals for the year

- Review last year’s expenses

- Forecast for the upcoming year

- Track your results against your budget

Step 1. Set goals for the year

The best budget is one that properly aligns with your company’s goals. When this happens, it’s easier to turn your budget into a useful tool for fleet success. To build your budget strategy, you’ll need to set specific goals for your fleet and align your budget to help reach them.

A great method for determining company goals is a SWOT analysis. This type of analysis is a tool for identifying your business’s strengths, weaknesses, opportunities and threats. For example, your strength may be adaptability, but your weakness is high idling levels. This could lead to building a goal to implement a new program to reduce idling and thus fuel costs over the next year.

Another opportunity you may have is to begin incorporating electric vehicles (EVs) into your fleet to combat the threat of competitors who have already begun to do so and to align with global sustainability goals. This would present an opportunity to build the costs of new or used EVs into your budget.

Ultimately, your goals should be to construct a plan for the business that touches on any changes that may occur in the coming year. The goals will set the foundation for the budget.

Step 2. Review last year’s expenses

Gathering information on previous costs provides a guideline of what expenses need to be included in the new budget. A review of past expenses can also highlight areas for improvement. For example, if fuel expenses were much higher than planned, a driver coaching program to reduce idling and speeding might be in order.

In addition, it’s important to reflect on past expenses and ask questions such as:

- Did you overspend or underspend?

- What were the largest areas of expense?

- Are there areas of the fleet that were underutilized and could be better optimized?

- What unexpected expenses came up and why?

- What efforts were made to cut costs and were they successful?

These kinds of questions can help shape the future of your fleet. They can also provide good reference points to look back on throughout the year to make sure your budget stays aligned.

Step 3: Forecast for the upcoming year

When preparing a budget, there are different budgeting techniques that can be used. One common method is incremental budgeting. In this method, a flat increase is added to the previous year’s expenses, e.g. 5%. While this method may be faster, it has certain flaws.

Firstly, it doesn’t take into account whether the previous year’s spending was necessary or appropriate. Secondly, a straight increase doesn’t give managers any reason to cut costs. In this way, incremental budgeting may actually promote increased spending.

A zero-based budgeting approach is more rigorous. Every item in the budget must be justified from zero, not just the changes from the previous year. Even though this process can be more time-consuming, zero-based budgeting helps develop a culture of cost-management in the organization.

Some key line items for a fleet management budget include:

- Fuel

- Maintenance

- License and taxes

- Disposal adjustment

- Leasing and fleet management

- Insurance and collisions

- Personal use chargebacks

- Vehicle depreciation

- Interest expenses

- Safety

Step 4: Track your results against your budget

After you’ve defined your fleet goals, reflected on the finances from previous years and developed a plan for the upcoming year, it’s essential to keep everything in alignment. This means regularly checking fleet metrics against your goals to benchmark against previous years to stay on track.

For example, measuring fleet productivity and managing downtime is an essential step to controlling unnecessary expenses. If you ever notice that your fleet is falling behind, don’t be afraid to introduce new solutions or programs that can help your fleet get back on track.

As with any goals, regularly checking the expenses against the planned budget is critical to staying on track. Benchmarking the budget against previous years or comparable fleets can provide further insight as well.

How telematics can help build a better fleet management budget

All fleets, whether small or large, private or public, need to have a budget. A well-defined budget helps set the organization on a path to success.

Telematics is especially useful for the budgeting process. Managers can use data insights to identify new opportunities for cost savings. Once the budget is set, fleet managers can control costs by using telematics to monitor fuel consumption, optimize routes and proactively manage vehicle maintenance.

Learn more on how you can optimize your fleet operations on the Geotab Blog