Integrated powertrains can offer multiple advantages to fleets compared to a traditional manual and legacy automated transmission-based systems, noted Kristopher Ptasznik, powertrain total cost of ownership and consultancy leader at Cummins.

“Traditionally, drivers can account for up to a 30% difference in a fleet’s fuel economy,” Ptasznik said. “By making it easier to operate the vehicle more efficiently, an integrated powertrain can drastically reduce that variation. Increased communication capabilities between the engine and transmission with new integrated powertrains also provide for faster shifting capabilities, load management logic, and allow for the development of future driver-focused features.”

“The components in an integrated powertrain work together to benefit the overall performance of the truck by providing a smoother, more efficient and safer driver experience,” said Len Copeland, product marketing manager at Detroit Products. “Integrated powertrains also are central to improving vehicle connectivity and performance by communicating and interacting seamlessly.”

Johan Agebrand, director of product marketing at Volvo Trucks North America, related that integrated powertrains can offer efficiency and performance benefits that are not always achievable in non-integrated engine and transmission combinations. “The basic fundamental when we talk about integrated powertrains is that the components fully communicate and collaborate,” he said. “That is done through algorithms in software that are optimized to have the most information available based on vehicle architecture.

“Fleets can see the benefits of integrated powertrains in efficiency, and in unique software calibrations and functions for different driving conditions,” Agebrand continued. “Non-integrated powertrains would have to consider all possibilities. Those systems usually have to accept lower optimization and performance levels in order to deliver reliability and quality.”

When deciding to specify an integrated powertrain, fleets should consider the application and the specs of the truck, Agebrand added. “Integrated components are always designed to work together where non-integrated components will always have to work with other components,” he said. “Fleets should definitely think about the value of simplicity that integrated components can offer.”

Kristopher Ptasznik at Cummins noted that depending on the type of operation, some fleets may feel they have greater control of their payload or vehicle while using a manual transmission compared to an automated transmission. Driver preference may impact a fleet’s powertrain specs as well.

“If you have a pool of drivers who prefer manual transmissions, you might want to slowly introduce an integrated powertrain to allow them to become comfortable,” Ptasznik said. “Conversely, a fleet might find it easier to recruit or hold onto drivers who prefer automated transmissions. In any case, drivers need to be informed of any changes to the powertrain so they understand how the vehicle is designed to operate.”

Having the right spec for the job is the best way to order any truck, noted Detroit’s Len Copeland. “When a fleet is spec’ing a powertrain for their respective type of operation, they need to make some choices such as engine displacement, transmission type and axle ratio,” he said. “They should also consider factors such as driver comfort and how different components can support driver training, recruitment and retention.”

Volvo’s Johan Agebrand pointed out that drivers and technicians will need training on integrated components, just as they would need similar training on non-integrated components. “We hear the argument that fleets want to utilize only one engine supplier or one transmission supplier due to the fact they are trained on those components,” he said. “What many fleets may be overlooking is that even those components evolve and will need new tools and continued training.”

Integration details

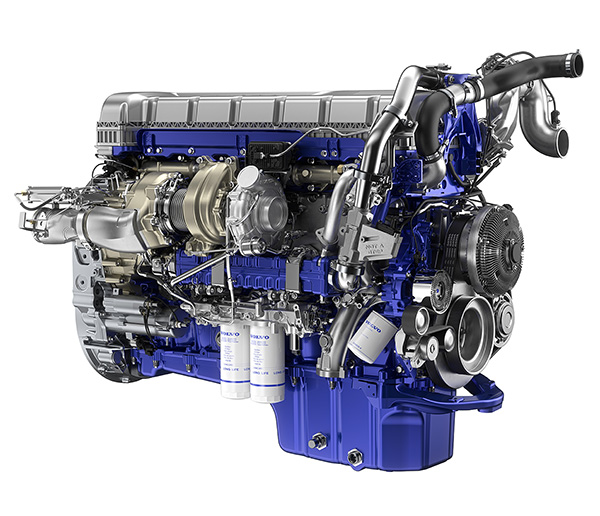

Volvo D11 and D13 engines can be matched with the OEM’s I-Shift 12-speed automated manual transmission in an integrated solution.

The Detroit Integrated Powertrain combines Detroit DD15 or Detroit DD13 engines with the manufacturer’s DT12 On-Highway series automated manual transmission.

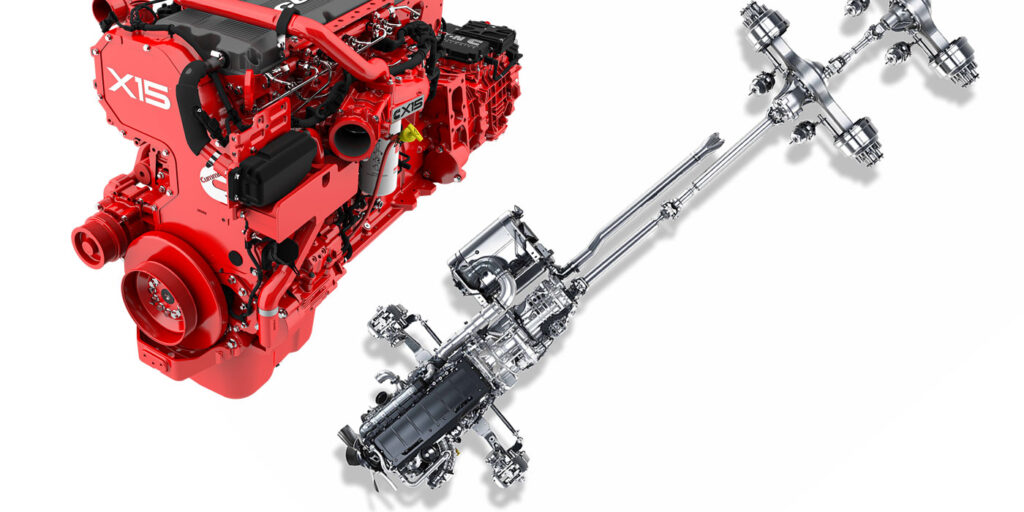

The SmartAdvantage Powertrain is configured using a Cummins ISX15 engine with SmartTorque2 and SmartCoast options paired with an Eaton Fuller Advantage 10-speed automated manual transmission. The Cummins diesel power portfolio also features integrated solutions that pair Cummins X15 or X12 engines with the Endurant HD 12-speed automated transmission from Eaton Cummins Automated Transmission Technologies.

Eaton, which collaborates with truck and engine manufacturers to offer integrated powertrain packages, provides the Eaton Fuller Advantage Series Automated 10-speed transmission with PACCAR MX-13 and International N13 engines.