Fleet managers play a pivotal role within their organization. Knowing which vehicles are in use at all times, keeping on top of maintenance and encouraging safer driving behavior while reducing costs requires a large amount of time and resources. Luckily, new technologies such as real-time vehicle tracking can help. At its core, vehicle tracking pinpoints vehicles on online maps in real-time or over a defined period, allowing fleet managers to access a wealth of data without having to distract drivers from their important duties.

Vehicle-tracking is not just for big companies: all types of businesses can benefit from its advantages, and providers offer scalable options to fit their customers’ needs. Many solutions offer functionalities such as online timesheets, route reports, driving-safety analysis and maintenance-tracking tools, leading to a safer and more efficient work environment. Here are some of the reasons why vehicle tracking can be a powerful tool for fleet managers to cut costs and increase productivity.

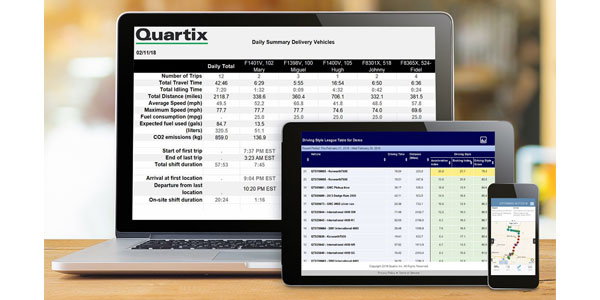

With GPS vehicle tracking, fleet managers can track their fleet in real-time, anytime and anywhere. Some solutions allow users to track their fleet on a map from any connected device, mobile, tablet or desktop, making it easy for fleet managers to access the data on the go. Quartix, a leader in the industry with over seventeen years of experience, offers a tailored dashboard that allows users to monitor the percentage of vehicles in use for each hour of the day or each day of the week and keep track of their vehicles’ activity in real-time.

Automatic data collection ensures fair fuel and overtime pay while helping fleet managers crack down on false claims. Further savings on fuel expenses can be made by monitoring and improving driver behavior thanks to driving style reports or reducing unauthorized vehicle usage with geo-fencing. Frost & Sullivan estimates that the effective deployment of a fleet management system leads to a 20% to 25% reduction in fuel expenses and a 10% to 15% decrease in overtime.

By monitoring driver behavior, vehicle tracking helps fleet managers spot the drivers who take too many risks. They can then incentivize safer and more conscious driving in order to reduce fuel consumption, violations, accidents and idling which, in turn, can help lower insurance and maintenance costs. Additionally, functionalities such as maintenance reminders simplify the workload of fleet managers to improve their productivity. According to Frost & Sullivan, a fleet management system that incorporates vehicle tracking can help fleet managers improve their productivity by 10% to 15%.

Comprehensive reports sent by email help fleet managers reduce their heavy workload, make sense of mileage and fuel costs, and remove regulatory paperwork headaches.

Finally, location pinpointing can come in handy in many situations, whether to locate a stolen vehicle or to send assistance in case of accident and illness, or if an employee doesn’t turn up when expected.

One provider—Quartix—has delivered real-time vehicle and telematics solutions for over 17 years. Nearly 10,000 businesses have chosen Quartix because it offers:

- Tiered pricing options that let them select the level of functionality they need

- Shorter contracts that don’t require multi-year commitment

- Contracts that do not auto-renew

- Customer service by experts invested in their success

To learn how Quartix can help you better serve your business, your employees, and your customers, visit www.quartix.com.