When Fleet Equipment caught wind that Meritor is using a unique lube management systems on its new 14X HE tandem axle, we wanted to know more. So we caught up with Ken Hogan, Meritor’s vice president for rear drivetrain, to find out how it works, what the benefits are for the axle and what other advancements may soon be in the offing.

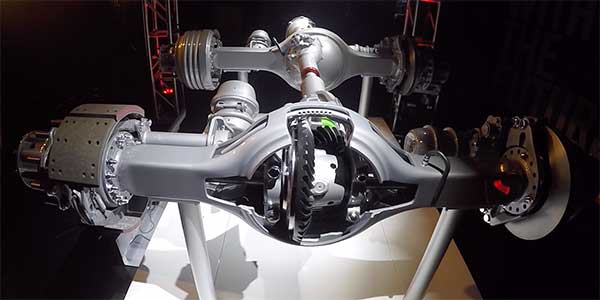

“The main benefit to the lube management system is that it enables our axle to lower the lube level while it’s moving at speed,” Hogan says. “It takes the oil and runs it through tubing and delivers it out to the wheel ends, and then it holds it in place there, lowering, effectively lowering the lube level, which reduces all of the friction losses that you see in the axle, one of the main contributors to the efficiency gain you see in the 14X HE. For starters, there is actually less lube in the system, which funnels in and it exits through drains as the axle slows down it can drain back in. So, when you go to start the truck back up again, it has all the oil it needs in that area.”

While less lubrication may seem counterintuitive, it has a better result.

“The reason for that is that it’s less viscous with less churning in the system,” Hogan explains. “That means less parasitic loss. Therefore, it takes less power and makes the whole axle more efficient. There are three main things that help to drive the efficiency. One is the high efficient bearings installed in both the forward and the rear. We have a spiral bevel gear design in the rear, which also contributes to lower friction losses, and then we use the passive lube system as well. Meritor plans to put the lube management systems on nearly all of its axles that are used in North America. We think it’s a cost-effective way to help improve efficiency in all of our axle products.”

What about downspeeding?

Meritor has fast ratios available with the new axle for fleets that frequently downspeed.

“I would expect the trend [of making fast ratios available] to continue,” Hogan says. “What we’ve seen since launching our faster ratios is that we now have nearly a quarter of the market. We launched a 2.28 a year ago, and we’re starting to see a pretty decent take rate on a 2.28. This axle has a 2.15 ratio available. So, we’re sure to see, as that engine slows down, more take and in the future, we’re developing axles that are going to be at 2.0 or lower, for that matter.”

Hogan adds that the company’s next generation of axles, will have a 1.8 range.

“We’re also testing and doing some development on trucks where the ratios could be low as 1.6,” he says. “I know that sounds a little out there, but we are taking a look in case that ratio is needed in the future.”

When it comes to enabling faster ratios, Hogan says that the size of the pinion head and a ring gear are pivotal.

“As the ratios get faster, this hardware actually gets larger,” he says. “That ring gear is getting bigger, and that pinion head, in particular, is getting larger, and that generates more revolutions.”

Meritor plans to introduce 20 new products within the next three years. Hogan says that these will be rolled out across the globe, in several of the company’s segments for on-highway, and off-highway.

Integration is a huge talking point now, specifically mating the transmission and the engine, but it’s spilling into the axles and smart driveline/powertrain management. Hogan says Meritor is working with others in the industry.

“One of our customers employs a vertically integrated strategy. However, we still offer our axle to their customers,” he says. “We’re also working with Cummins and Eaton to have an integrated package together and just have that system and be able to offer that to fleets as well.”

Telematics

Meritor wants to be able to offer new technologies as they become available.

“For example, we think axle load sensing would be a great feature to be able to offer customers,” he says. “We’re taking a look at our brake products, our driveline products, our axle products and wheel ends, for things that can help customers mostly for a predictive or uptime point of view. Taking a look at heat, taking a look at temperature, and seeing if there is any bearing life that can be prematurely failing, so they can see it before it breaks.”