You’ve probably heard the old adage “Rome wasn’t built in a day.” It was most likely in regard to a slow but steady climb towards a bigger picture. The paradigm is especially relevant to the commercial trucking industry, as ambitious sustainability initiatives are on the forefront for every manufacturer.

Due to the plethora of different applications, components, technology integrations, environmental conditions and predictive features, there isn’t a one-size-fits-all path to achieving zero emissions. As each OEM continues to forge its way to greener solutions, International took a “start from scratch” approach with innovative technology that takes the company one step closer to the ultimate goal: zero emissions.

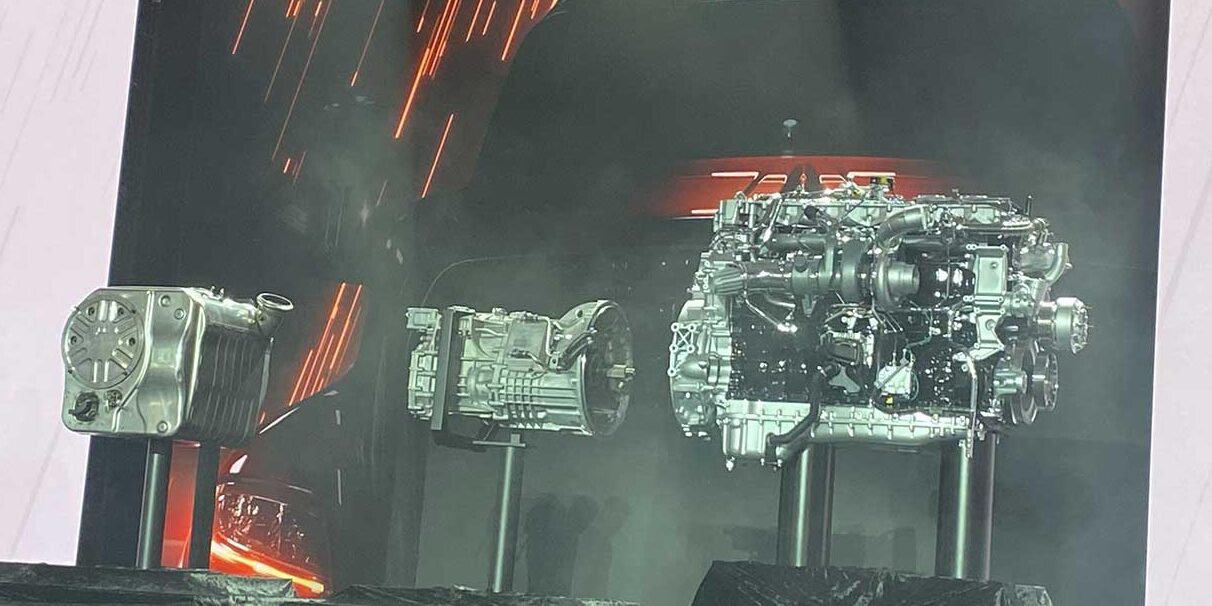

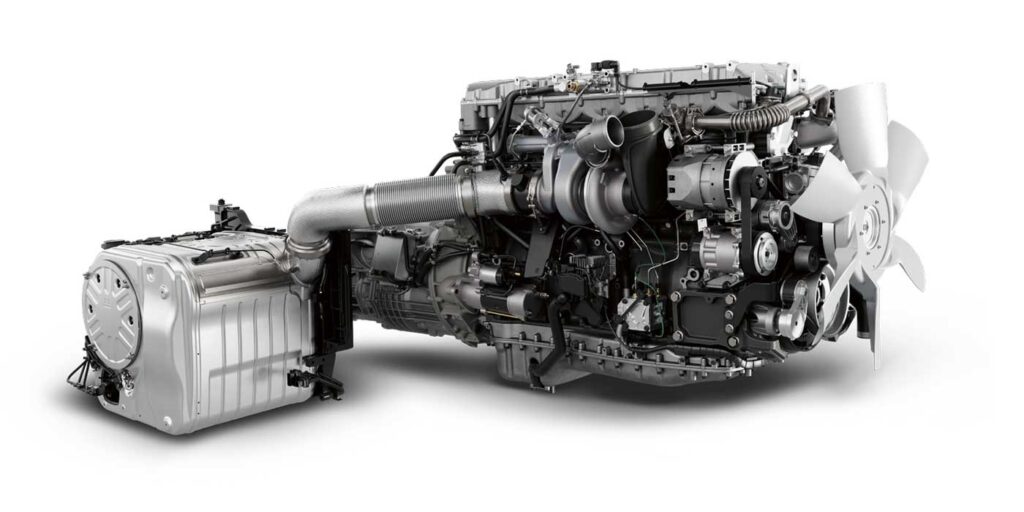

The introduction of its new S13 Integrated Powertrain was developed from the ground up. The engine, transmission and aftertreatment system were all refined simultaneously to ensure maximum compatibility between each of the components. As electrification continues to make advancements in the industry, International anticipates that this system will be the last diesel fuel engine they introduce.

Enough background. Let’s shift gears.

Shifting what’s possible

The event took place at the Las Vegas Motor Speedway and was kicked off by International’s CEO and President, Mathias Carlbaum; Executive Vice President of Commercial Operations, Göran Nyberg; and Executive VP of Operations, Michael Grahe.

Elaborating on the importance of increasingly sustainable technology, International was out to demonstrate its continuous efforts toward lowering emissions through the introduction of its new and improved powertrain technology, the S13 Integrated.

Going green and saving green

Built from the ground up, the company says the transmission, engine and aftertreatment system were developed concurrently to ensure optimal performance. International’s team of engineers used its decades of combined experience to improve the design and functionality of the system, boosting fuel economy by up to 15% compared to their A26 engine.

Off to the races

With full torque available starting at 900 RPM, the truck’s test drive was a smooth and quiet one.

Click here for more about the S13 Integrated Powertrain.