Kimberly Riccio; Kevin Johnson; Richard Trotta; Kyle Johnson; Marti Reed; Kent Johnson; Patricia

Johnson; Tanya Johnson; and Connie Johnson.

On the truck (left to right): Kenneth Johnson;

Ridgley Johnson; and Catherine Johnson.

To get the most out of its trucks, Leonard’s Express, a family-owned asset-based transportation provider headquartered in Farmington, N.Y., invests heavily in predictive analysis. The fleet is continuously working to stay one step ahead of the curve, working to keep its trucks running productively each day. As Leonard’s Express Chief Information Officer Kyle Johnson puts it: “If we can’t measure it, we can’t get better at it.”

As a company with diversified transportation services operating across multiple locations—Farmington, N.Y.; Eau Claire, Wisc.; Wilmington, Del.; Atlanta; and a long haul division that carries refrigerated food products to the West Coast and Florida—Leonard’s Express is faced with challenges unique to each location. With the guidance of tracking and data systems that measure tire performance, fuel consumption, odometer readings, vehicle inspection reports, engine performance and maintenance performed, Leonard’s Express is able to set up vehicles domiciled in each location to perform optimally within its operating local.

Given that the company operates in different markets, Leonard’s Express must also rely heavily on dealer relationships. Johnson explains, “For example, we buy a different brand truck in Wisconsin versus in New York simply because of the dealership network available in Wisconsin versus New York. The ability to get our equipment serviced and get our parts efficiently is a big factor.”

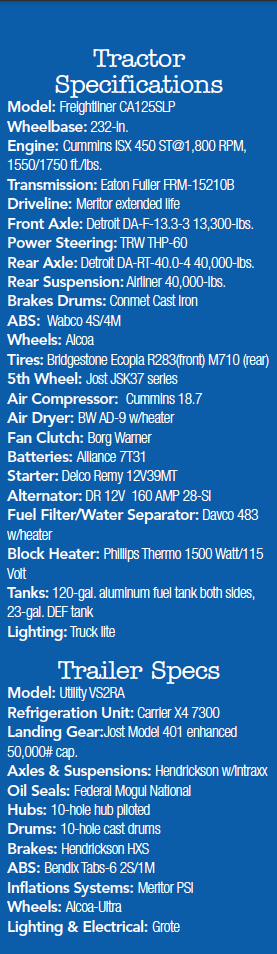

The multiplicity of truck brands (the company owns primarily Freightliner and Kenworth sleepers and day cabs, and a few other brand trucks such as Navistar and Volvo) purchased by Leonard’s and operating environments makes data that is specific to the brand and application invaluable to Leonard’s operations.

To address each location’s specific concerns, Leonard’s utilizes TMW Systems products to monitor all tractor performance. These products include TMT Fleet Maintenance and Service Center software to track maintenance schedules, TMT Tire Management Module to track tire performance, Omnitracs Satellite Tracking, which, among other things, reports odometer readings and emission components performance. The company recently implemented the Tire Management Module and Johnson is particularly interested in what it will uncover.

“Those will be very hard, trackable numbers that we’re really excited about being able to get,” Johnson notes. “We can use those numbers, to help better coach the drivers. If we have two trucks set up identically and one truck’s tires are wearing better, that’s likely to be a driver problem. We can then go in and compare what that one driver is doing against the others and use that information for the future.”

“Those will be very hard, trackable numbers that we’re really excited about being able to get,” Johnson notes. “We can use those numbers, to help better coach the drivers. If we have two trucks set up identically and one truck’s tires are wearing better, that’s likely to be a driver problem. We can then go in and compare what that one driver is doing against the others and use that information for the future.”

Johnson relates that the data from TMT Fleet Maintenance and Service Center has specifically benefited Leonard’s service center, Johnson Equipment. Johnson Equipment is a separate company that shares the same ownership as Leonard’s and handles all of Leonard’s maintenance. Johnson Equipment also services other fleets and even passenger cars, but the majority of the company’s business—60%, Johnson says—comes from Leonard’s.

“We have 40 technicians total that operate across two Johnson Equipment locations in Eau Claire, Wisc., and Farmington, N.Y. We track all of our maintenance for our fleet, as well as customer vehicles through the TMT software,” Johnson notes. “As for our own trucks, we track anything that happens—whether it’s a flat tire road call or a driver that replaced a marker light on the road—and we enter that information into the TMT Asset Maintenance software. Work that is done in our own shop is documented as well.”

With that information, it is possible to track all expenses related to each individual vehicle. Johnson says that the company has also been able to keep track its on-the-road repairs, which are “a lot more expensive than getting the repairs done in our own shop.”

The service center and the company has benefited from the tracking and adjusting its preventative maintenance schedules based on the information gathered. For example, it can make better decisions on when to replace a part to reduce the risk of it being repaired on the road. Sometimes, that means pulling parts well in advance of a manufacturer’s recommendations, especially in the case of diesel particulate filters.

“Filters are so expensive to take care of on the road so with that data we’ve set our own guidelines as far as when to get the particulate filters cleaned,” relates Johnson. “Let’s say the manufacturer recommends that we clean out the particulate filter every 100,000 miles; we’re doing preventative maintenance checks every 25,000 miles so the predictive analysis might indicate that we should pull that particulate filter at the 75,000 interval instead of waiting until the 100,000. That allows us to prevent that a roadside failure.”

Focus on maintenance and data

Focus on maintenance and data

For Leonard’s Express, a strong maintenance program coupled with data collected from onboard information systems has contributed to the success of the company. Going forward, the fleet will continue to invest in predictive data that will better its operations.

“We have found in our company that if we can measure it, we can get better at it. Whether it’s a tire or fuel purchases or fuel idle time—any of those things—if we can get the data then we can make better choices.”