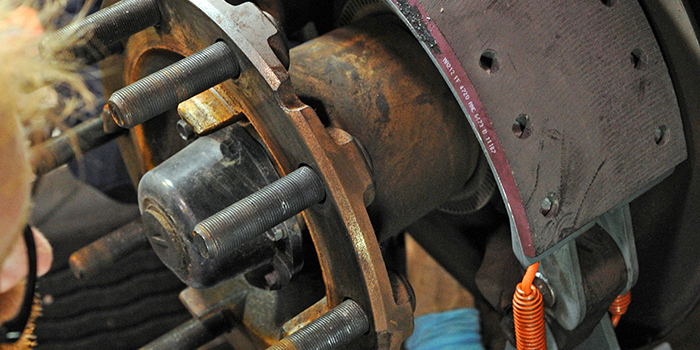

While Air Disc Brake market penetration has pushed into the tractor and trailer segments at approximately 20% (Give or take 5% either way depending on who you talk with), the majority of trucks on the road still use drum brakes.

The first major difference between disc and drum brake friction is heat. Disc brakes operate, and can withstand, much higher temperatures than their drum counterparts. Drum brakes will typically operate between ambient and 300°F in service (depending on the application), while disc brakes in the same application would operate between ambient and 600°F. Disc brake friction should be made to perform at these higher temperatures, and since the rotor is exposed to air, it constantly cools the brake and helps fight brake fade.

The second major difference is that surface area of disc pads is roughly one-half to one-third of equivalent drum brakes, but you still need to stop the truck. This means disc pad friction material must be formulated to withstand two to three times the energy per square inch. Application pressures are more than four times higher on disc brake pads as compared to drum brake shoes.

When it comes to spec’ing friction for either, try not to mix and match your friction brands and quality based on wheel position. Mixing friction has the potential to adversely impact stopping distances.

Additionally, Mixed quality of friction may lead to a brake imbalance on the trucks, which often leads to increased brake maintenance costs.