If you’re a fan of comic books, you’re no doubt familiar with the adage, “With great power comes great responsibility.” But when it comes to the trucking industry and the potential of combining lithium-ion and solar technologies, the axiom is, “With great power comes great reliability.”

Many fleets are seeking power solutions that represent clean energy. Fleet managers are faced with the challenge of needing more power, but without increasing the number of autostarts or hours idling. Due to tighter idling regulations and the constant pressure to increase efficiency, fleets are constantly searching for new technologies to reduce both fuel and maintenance costs.

Many fleets use Auxiliary Power Units (APUs) to reduce truck engine runtime, maintenance and fuel usage. There are two types of APUs commonly used today: diesel-powered and battery-powered. Diesel APUs practically eliminate truck engine idling for hotel loads, but still require some fuel and maintenance themselves (although much less than idling the truck engine). Battery or electric APUs do not require maintenance or fuel, but do auto-start the truck from time to time when the batteries need to be recharged.

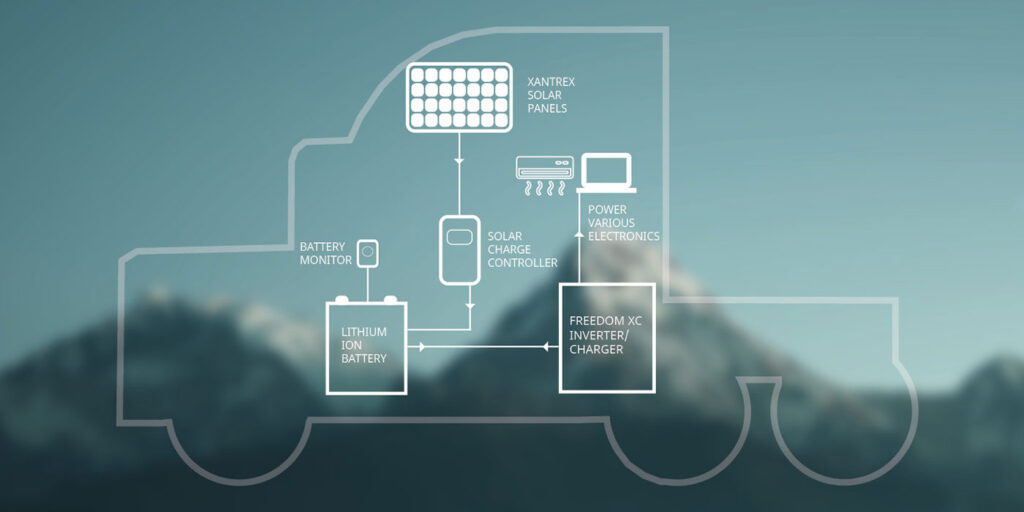

With technology advancing, there’s now a third solution to run all your electronics including climate systems. Using an inverter charger paired with a lithium battery pack can provide both DC and AC power solutions to run all sleeper cab hotel loads, including HVAC, without fuel, maintenance or truck auto-starts. Adding a solar panel to the system will ensure that the batteries stay topped off, and that you will virtually never run out of power when managed properly.

This is possible because lithium batteries can be completely discharged without damage and provide up to six to eight times more cycles than the typical deep cycle battery; so if you have a 600 amp hour lithium battery, you have 600 amp hours of usable power. Lead-acid batteries, on the other hand, can only be discharged 50% at most without causing them damage. Most commercial vehicles have 400-amp hour battery banks, which only gives you 200 amp hours of usable power. Making that even less effective, most OEMs only allow you to discharge the batteries 30%, so in that case, you’re hardly getting any usable battery power at all.

You might think more capacity means more bulk, but just the opposite is true as Li-Ion batteries are 60 to 80% lighter than their lead counterparts. A typical Group 31 battery weighs about 75 lbs. while a similar Li-Ion battery only weighs 28 lbs.

Since most trucks are on the road seven to ten hours every single day, the truck alternator provides enough power to charge the lithium pack. Adding solar is the icing on the cake to keep the battery fully charged and extend its lifespan. Solar acts as a secondary charging source for house batteries, liftgate batteries and battery-based APUs—all of which can lead to downtime and lost productivity if not properly charged. Park a truck and measure how much power is being depleted out of the battery: it’s significant. All the computer sensors and electronic devices in the truck are constantly drawing power. If you’re just off-venting parasitic loads, which is the major issue with sleeper cabs, a 165-watt solar panel measuring approximately three by four feet is sufficient and can be mounted inconspicuously in places on tractors, including roof fairings and sleeper roofs—areas that have direct access to sunlight. Thinner, flexible solar panels also mean improved aerodynamics.

Answering solar power FAQs

Isn’t solar dependent on the sun?

Technically, that’s true. But technologies have moved so rapidly that quality solar panels can actually harvest quite a bit of power even on cloudy days.

Will batteries discharge when connected to solar?

It’s a misconception is that batteries will never discharge when connected to solar, and that’s just not the case. It’s really about offsetting battery drain, and with solar power continually pouring in, it completely eliminates that issue.

Solar panels are typically connected directly to the batteries. The way it works is that solar is connected to a “charge controller” that might be on the panel itself or exist as an external device mounted in the cab so that you can see the data on how the panel is performing. That controller then regulates the power that’s coming off the solar panel, making sure it’s the right voltage for the type of battery.

Is a complete system with lithium, inverter charger and solar worth it?

A typical warranty on a traditional lead-acid battery is three years, but the importance of uptime can lead fleets to replace batteries much more frequently. Li-Ion batteries may cost more initially, but are a better investment in the long run since it can offer six to eight times more cycles and gives constant voltage through the entire cycle of the battery, and provide driver comfort benefits as well.

A recent Confidence Report from the North American Council for Freight Efficiency (NACFE) noted that solar panels “not only help the HVAC system make it through the night without draining the truck’s batteries, but also reduce the load on the alternator the next morning, resulting in fuel savings.”

Mitul Chandrani is the director of marketing at Mission Critical Electronics.