When it comes to tractor-trailer electrical connections, spec’ing and maintaining equipment is vital. This is especially true these days with fleets seeking to avoid CSA inspections that often lead to time off the road and costly citations.

Spec the best

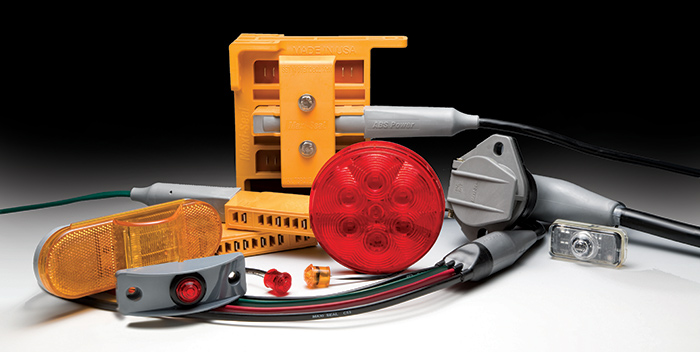

“At Peterson, we have been actively selling and promoting our Defender sealed, modular harness and lighting system for trailers to major fleets for approximately seven years now,” begins Mark Assenmacher, director of marketing for Peterson Manufacturing Co. “When a fleet specs a sealed system, like Defender, they are not only getting a better electrical system for their trailers, but also an extended warranty for both harness and LED lights. Buying a premium sealed system for trailers may cost the fleet a marginal cost increase upfront, but over the life of the trailer the cost of ownership will be less due to less maintenance, reduced down time, possible CSA violations, extended warranty, etc.”

“Some fleets still spec standard trailer wire harnesses and lights with the traditional PL3 and PL10 connectors, but these connections require vigilant inspection and maintenance,” Assenmacher continues. “These old fashioned, traditional connections are not as robust and are susceptible to failure due to corrosion if not well maintained with constant inspection and regular greasing of the connections with dielectric grease.”

Nowadays, if a fleet specs a premium, sealed LED electrical system for their trailers the chances are it may come with weather-resistant connectors such as AMP-style, Packard, Deutsch or sealed bullets. All of these connections should outperform industry standard connections such as PL3, PL10, and some male-pin connectors, Assenmacher says. The basic concern for the fleets are problems on the road such as CSA lighting violations or safety concerns resulting from intermittent “flickering” lights, diodes out on LED lights, voltage drop on double or triple trailer configurations, and simply non-functioning lights on the trailer.

Design excellence

“Much of a fleet’s success with its electrical system occurs at the design phase of the equipment that it uses—and is directly related to properly installed—secure and robust electrical connections,”

says Brad Van Riper, senior vice president and chief technology officer for Truck-Lite. “The primary development in electrical connection involves improved sealing of the entire wiring harness system.”

As the saying goes, a chain is only as strong as its weakest link; the same holds true with the wiring system. The selection of well-engineered connectors, along with improved wire and harness routings, can dramatically increase a fleet’s success in the long run. Similarly, fleets benefit from quality and consistency of standardized, sealed wiring and practices: one example is creating a drip loop, which prevents water from running down to the connector, as an installation practice.

Supplier focus

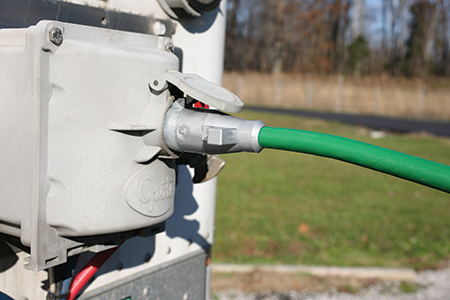

“Suppliers are focusing on power cords and connectors as well as the receptacles and nose boxes mounted on the front of the trailer,” says Darren Harmon, OEM regional manager for Grote. “From the power cord side some suppliers have updated their designs by adding external sealing rings to help prevent water intrusion into the receptacle area. Grote’s focus has been the plug durability, getting away from the plastic or hollow die cast plugs and using a zinc die cast plug filled with an elastomeric material that resist crushing and seals to the cable jacket via a patented bonding agent.

From the nose box and receptacle side, suppliers are focusing on meeting the SAE J560 guidelines and durability. Grote recently updated its Ultra Nose box by adding reinforcement ribs to protect against impact and improved the door latch and spring design to assure optimal plug retention.”

As for the latest developments, Mark Blackford, Grote’s national fleet manager, adds, “Grote is using sonic welded connections with ‘zero voltage drop’ Grote now ‘overmolds’ amp-type connectors to assure there are no leak paths of corrosion running from the wire.”

Connection protection

When it comes to protecting electrical connections, Truck-Lite’s Brad Van Riper says, “Good connections start with the selection of good connectors. The best connections are formed by sealed connectors, which are protected from road spray and contain a secondary lock that ensures that the connector is fully engaged. Truck-Lite’s variety of sealed, locking connectors stands up to moisture and debris, remaining resistant to corrosion. Used in conjunction with Truck-Lite’s line of corrosion-preventative products, these connectors ensure airtight and highly conductive connections.”

Grote’s Harmon says that some of the concerns fleets face include worn out plugs or terminals in the power cord plug, and broken or corroded pins in the nose box or receptacle. Blackford points out that fleets are sometimes confused about when to grease different types of connections.

Troubleshooting

“Preventative maintenance through regular inspection is always recommended,” says Peterson’s Assenmacher. “Inspect all connections for proper fit. However, if using a modular, sealed system do not open up any modular connections at the distribution module or Weather Pack connections. If there is a problem, start at the point of the problem and refer to Peterson’s Defender trouble shooting guide for best maintenance practices to keep the fleet’s warranty intact.”

Taking care of equipment

Grote’s Harmon agrees that preventative maintenance and taking care of the equipment is crucial and suggests: “For power cord plugs, use a holder on the back of the truck to secure the plug when not connected to a trailer. Don’t allow the plug to be dragged. Take the time to clean the plug every now and then with wire brushes supplied by power cord vendors. Look at the terminal and look for corrosion, damage or ware. Make sure the cable is still in the plug and there is no damage to the plug which would allow water intrusion into the connector and the terminal area. Adding dielectric grease to the terminals on the power cord plug can also help with protecting against corrosion.”

On the nose box, make sure the pins are in good shape, with no corrosion. Addition of small amounts of dielectric grease here can also help prolong life. If you are using a nose box with split pin terminals, be careful if you are trying to pry them open for better terminal contact. Too much is a bad thing, you fatigue the terminal material and create a weak spot that could potentially break off part of your terminal. A brush tool designed to clean the receptacle area should be used periodically to assure no dirt or corrosion is building up in the socket area. Grote and other vendors supply these cleaning brushes and tubes of dielectric grease.

If you have no lights or flickering lights, inspect both ends of your power cord (if not hardwired into the tractor), Harmon advises. “Inspect the nose box receptacle area,” he says. “Look for broken or missing terminals or worn terminals. Check to see how lose your plug is when inserted into the nose box receptacle. It should be a snug fit with very little movement.”

Training is key

“Any fleet can benefit from a comprehensive multi-meter training program,” Truck-Lite’s Van Riper says. “A TMC skills review found that electrical knowledge was one of the weakest areas among fleet technicians. It’s imperative to use multi-meter skills to get to the root cause of the problem, rather than to simply replace parts. The old-school method was to replace parts until the problem was found, in many instances throwing away perfectly good parts.

“However,” he continues, “using the multi-meter can effectively identify the problem part and greatly reduce the cost of vehicle maintenance. Truck-Lite’s warranty department experiences a high percentage of returned items that are fully functioning, indicating a weakness in troubleshooting skills among fleets. For that reason, we are adding a multi-meter training supplement to the Truck-Lite Training Institute (TTI), which will be available in early 2017.”

ABS connections

ABS connections

“There are several ABS tractor-trailer connection and communication options available today,” says Dave Engelbert, chief engineer for Haldex. “Wireless communications can be used with the above options such as Bluetooth and ZigBee. The following standards stipulate minimum tractor power output for the trailer ABS: SAE J2247 and TMC RPs 137 and 141.”

There are also light-out detection systems now available on the market that monitor current on each circuit. Below are some examples that a failed electrical connection can have on systems:

- CSA violations, fines and points for lighting failures.

- ABS does not function due to powering issues causing vehicle combination to lose control during braking and possibly jack knife.

- Trailer roll stability systems rely on the auxiliary (blue) power to function. Without adequate voltage at the blue pin the trailers do not have rollover protection available. There is no redundant back-up circuit.

- Electronic lift axle systems rely on auxiliary power. Continuous power is required to keep the lift axles raised (for safety reasons). If this voltage source is intermittent it could cause the lift axle to drop unexpectedly while the trailer is in motion, causing the possibility of tire damage.

- Tire monitoring and inflation systems rely on auxiliary power. If the connection is bad there is no warning of an issue to the driver, so proper tire pressures cannot be maintained.