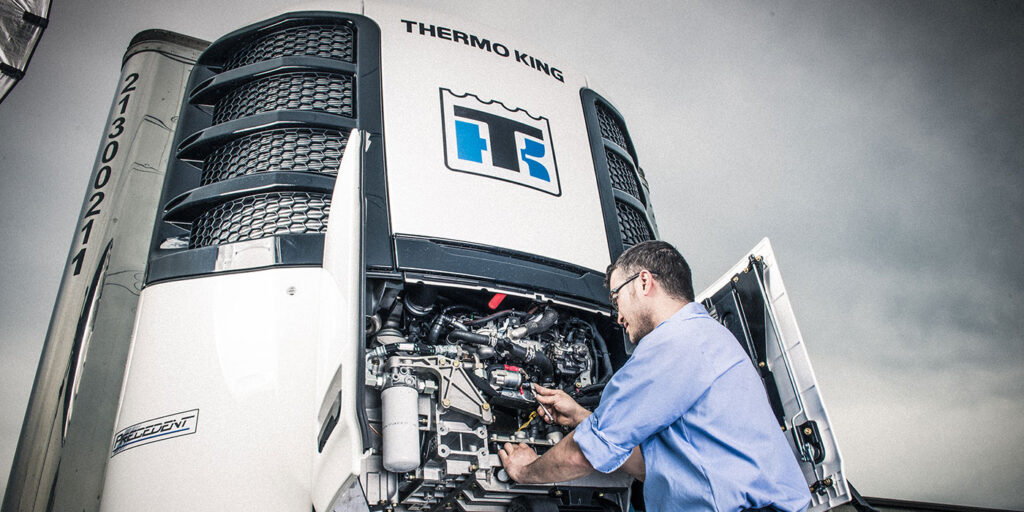

There’s a lot that goes into ensuring the safe and successful transport of temperature-sensitive goods. But there’s one thing you shouldn’t have to worry about: the reliability of your refrigeration unit. Completing an annual inspection, following the maintenance inspection schedule, and adhering to a pre-trip inspection before every load are just a few tips to follow to prevent costly repairs. Choosing a high-quality refrigeration unit, and getting it serviced regularly, will provide you with the reliability you need on the road and ensure a longer life cycle for your equipment.

Complete a planned maintenance inspection

Refrigeration unit utilization is typically high during the summer season and may not be available to perform the annual Preventive Maintenance. So scheduling Preventive Maintenance is vital to ensure proper operation of the unit before and after a busy season. In addition, it’s critical to complete an annual planned maintenance (PM) inspection. A thorough PM inspection will identify potential issues that could cause an unexpected breakdown.

At this time, you should also verify the condition of critical components such as belts, batteries, and air, oil, and fuel filters.

Other maintenance tasks:

- Inspect defrost drain hoses and flapper valves for dirt and debris.

- Check the unit for loose, frayed, or chaffing wiring.

- Examine doors and hardware.

- Look over software updates to ensure the unit is running on the latest software version.

- Complete a visual inspection of the unit for signs of leaks, i.e., refrigerant, oil, and coolant.

- Perform a “quick refrigerant level check.”

Paying close attention to your unit and getting it serviced regularly can extend its life cycle.

Follow a maintenance schedule

Unexpected repairs can cause an immense disruption in fleet operation, significantly if technician availability is reduced due to staggered shifts or social distancing safety measures. That’s why it’s essential to follow the Maintenance Inspection Schedule found in the unit maintenance manual.

The manual will help you or a service technician set up a normal cadence of maintenance and will serve as a guide through the inspection by highlighting critical areas. If your unit isn’t used frequently, you should start the units to recharge the battery and check that fuel has not gone stagnant or collected moisture. This will ensure that equipment will be in top shape when it’s returned to service.

A download of a unit — known as Service Watch download — can provide a history of the unit’s performance over the last three months. A trained Thermo King technician can review that information and provide insights into possible issues that may not have manifested into alarm codes.

Adhere to a pre-trip inspection

The last thing you want is costly repairs to your refrigeration unit. Following a pre-trip inspection will test the functionality of the system over a 15-minute comprehensive diagnostics check. The results will show a pass/check/fail code. In addition, the inspection is done independently of the operator so that other work can be conducted during the diagnostics check.

Thermo King’s automated pre-trip inspection checks multiple electronic component operations as well as cooling/heating operations. This helps ensure that the reefer is ready to protect the load.

As a good rule of thumb, drivers should never clear alarms without further investigation. The standard operating procedure will determine the next steps for each fleet.

Use telematics to remotely monitor your unit

Telematics can remotely monitor the equipment location and health status of your refrigeration unit. By utilizing telematics, such as TracKing from Thermo King, you and your fleet manager can act on items immediately to prevent breakdowns and reduce maintenance costs.

With TracKing, you and your fleet manager can monitor and react to selected codes the TRU may generate during operation. Having visibility to codes at the fleet manager level gives a different level of insight that was not previously available before the widespread use of telematics.

Today’s TRUs can set alarm parameters for maintenance events. For example, a TRU can be set to give you and your fleet maintenance manager a reminder at 1,500 hours to indicate that the unit is due for an inspection.

Be proactive

Proactive maintenance can save you time and money. One way to stay on top of maintenance is to use tools such as Thermo King OptiSet Plus to ensure optimal temperature control and engine run time while minimizing the potential for setpoint/mode errors. In addition, the OptiSet Plus package allows fleets to maximize unit efficiency and reduce run hours, which can extend the time between maintenance events.

In addition, you can install Thermo King ThermoLite solar panels on refrigeration units to help maintain battery voltage. Maintaining battery health is critical to reducing some of the most common out-of-service issues. With many units connected to cellular communication devices which create a parasitic load on the batteries, it’s critical to maintain battery voltage.

As you know, maintaining your refrigeration unit is a necessary but often overlooked step. By paying close attention to your unit and following these five tips, you can proactively avoid potential problems that may occur with your refrigeration unit and ensure the safe and successful transport of temperature-sensitive goods.

This article was written by Scott Koch and Freddy Muñoz. Koch has been with Thermo King since 1999, starting as a trainer in the Education Center for truck, trailer and bus products before moving to the district service manager role in 2003. Muñoz has been the north east district service manager since 2005 and is now the strategic account service manager for National Leasing Companies in North America and Canada.