With ongoing development, the latest technologies for axles on heavy-duty commercial vehicles are focused on maintenance and performance improvement. Recently, Fleet Equipment spoke to several heavy-duty axle manufacturers about design initiatives, new axle specifications and the advent of electronics. Taking part in the discussion were:

• Steve Mastroianni, senior manager of product planning, Dana

• John Bennett, vice president and chief technology officer, Meritor

• Sean Whitfield, marketing director, Hendrickson

What are the latest developments in axles for commercial vehicles, and what needs or trends were those changes designed to address?

Mastroianni: In order to meet Phase 2 greenhouse gas (GHG) regulations, developments in steer and drive axles have focused on lightweighting, downspeeding and torque carrying capabilities. To support engine downspeeding for line-haul applications, drive axles are engineered with faster ratios that can handle higher axle input torques which result from lowering engine RPM at highway speed. Also, with increased use of 6×2 configurations, single drive axles can be designed to accommodate super-fast ratios and enable engine downspeeding.

Additionally, as the industry continues to progress into electrification, innovation continues for drive axles that will successfully couple with electric powertrains. This includes designing to regenerative torque load requirements as well as integrating the right axle for electrified applications.

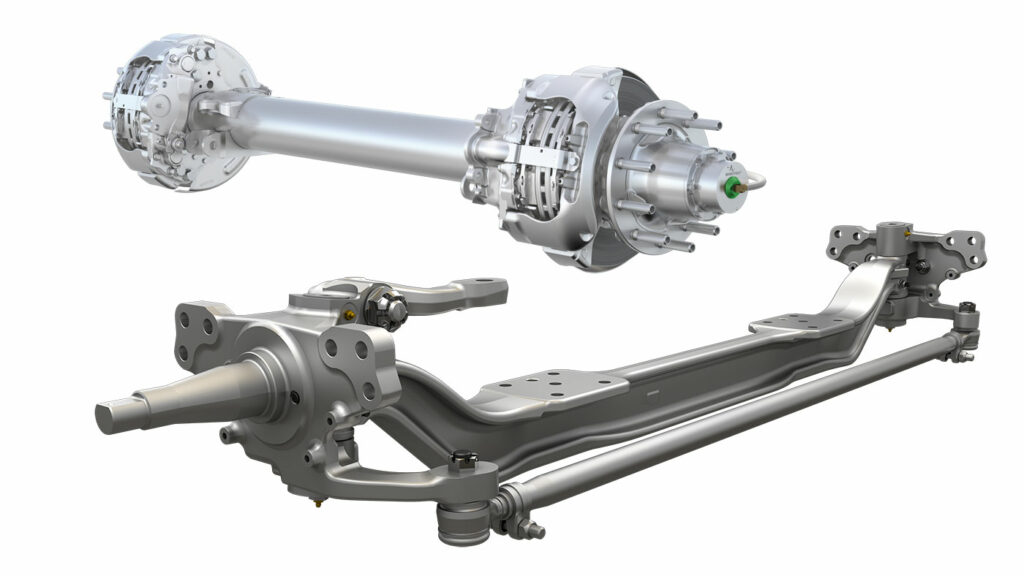

Bennett: Current developments for drive axles have been focused on reducing greenhouse gas (GHG) emissions by lowering efficiency losses through high efficiency gearing and bearings. Also, faster ratios are enabling diesel engines to run at slower speeds. On the steer axle side, the focus has been on weight reduction through integration at the wheel end of steering arms, tie rod arms, spindles and torque plates.

Looking toward the future, with a lot of activity taking place for electric vehicle technologies, there is an opportunity for electric motor and transmission integration into the axle itself. That will result in very compact, power-dense systems that allow for packaging more batteries in the vehicle to help increase operating range.

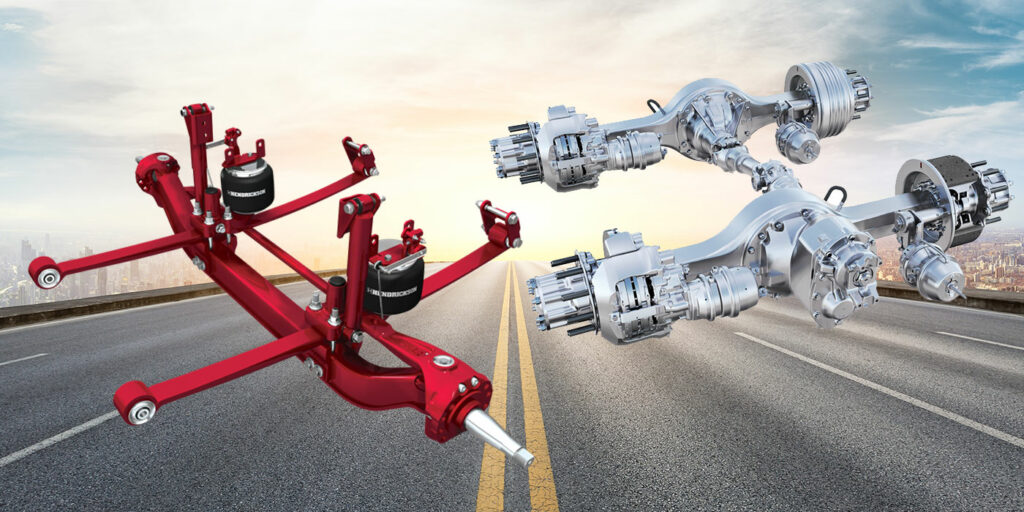

Whitfield: The market continues to demand lightweight products that offer improved performance, whether for serviceability, improved ride or enhanced handling. For example, steer axle systems have optimized kinematics with minimized bump steer and roll steer. This results in decreased transmission of road feedback to the driver whether it is through the seat or the steering wheel, which can contribute to a reduction in driver fatigue.

With the evolution of integrated powertrain offerings, how have axle designs and specifications changed?

Bennett: This gets back to developing faster, lower numerical ratios and changing gear designs in axles so engines can operate at slower speeds. Generally, the focus is on improving the capability of gear sets, bearings and drivelines to accommodate the shift. That results in a greater benefit to overall system performance.

Mastroianni: Integration includes axles that are synchronized to a vehicle platform and powertrain technologies. Additionally, axles offered with customization provide the design to meet today’s extensive application requirements. Added to that, understanding the relationship between the axle and the driveshaft in today’s downsped drivetrains is critical. Coupling the right driveshaft with the right drive axle to mitigate issues like noise, vibration and harshness is crucial when it comes to the different vehicle harmonics produced when an engine is operating at a lower speed.

As vehicle manufacturers increasingly incorporate electronics, what features, capabilities and benefits will those systems bring to axle performance and maintenance?

Whitfield: Liftable forward 6×2 axles designed to improve efficiency can use systems that sense fifth wheel loads and automatically lift the forward tandem axle when a deployment threshold, determined by the tractor configuration, is achieved.

Bennett: The industry is starting to look at what type of telematics and sensor information they can use to further reduce maintenance costs and be more proactive about service. The focus is on integration of sensors in vehicles. For axles, telematics can monitor parameters such as temperature, vibration and even weight. Integration of weight or load sensors can tell a driver exactly how much load is on each axle so fleets can rest assured that they are operating safely within legal limits. Similarly, via telematics we can monitor vibration and provide the fleet manager with an indication that a bearing will soon require replacement before it causes more damage resulting in larger service bills.

Mastroianni: In tandem with axle electrification initiatives, there is also innovation around axle preventative maintenance sensoring. These health monitoring technologies could potentially focus on maintenance issues such as lubricants, steer axle alignment and overall structural health, just to name a few.